Moscow 1995

Developed by the Central Research Institute building structures(TsNIISK) named after. V.A. Kucherenko State Construction Committee of the USSR.

With the entry into force of this chapter of SNiP, chapter SNiP 11-6.2-71 “Stone and reinforced masonry structures. Design standards".

Editors - engineers F.M. Shlemin, G.M. Khorin(Gosstroy USSR) and candidates of technical. sciences V.A. Kameiko, A.I. Rabinovich(TsNIISK named after V.A. Kucherenko).

At the end of the document there is an amendment to SNiP II-22-81, approved by Decree of the USSR State Construction Committee dated September 11, 1985 No. 143.

When using a regulatory document, you should take into account the approved changes to building codes and regulations and state standards published in the journal "Bulletin of Construction Equipment" and the information index "State Standards" of the Russian State Standard.

1. General Provisions

1.1. The standards of this chapter must be observed when designing masonry and reinforced masonry structures of new and reconstructed buildings and structures.

1.2. When designing stone and reinforced masonry structures, the following design solutions, products and materials should be used:

a) external walls made of: hollow ceramic and concrete stones and bricks; lightweight brickwork with slab insulation or backfill made of porous aggregates; solid stones and concrete blocks on porous aggregates, porous and cellular concrete. The use of solid masonry made of solid clay or silicate bricks for the external walls of rooms with dry and normal humidity conditions is allowed only if it is necessary to ensure their strength;

b) walls made of panels and large blocks made of various types of concrete, as well as brick or stones;

c) bricks and stones of grades with a compressive strength of 150 or more in buildings with a height of more than five floors;

d) local natural stone materials;

e) solutions with antifreeze chemical additives for winter masonry, taking into account the instructions of Section. 7.

Note. With appropriate justification, it is allowed to use design solutions, products and materials not provided for in this paragraph.

1.3. Application of silicate bricks, stones and blocks; stones and blocks made of cellular concrete; hollow bricks and ceramic stones; semi-dry pressed clay bricks are allowed for external walls of rooms with wet conditions, provided that a vapor barrier coating is applied to their internal surfaces. The use of these materials for the walls of rooms with wet conditions, as well as for the external walls of basements and plinths, is not allowed. The humidity conditions of the premises should be taken in accordance with the chapter of SNiP on construction heating engineering.

1.4. The strength and stability of structures and their elements must be ensured during construction and. operation, as well as during transportation and installation of elements of prefabricated structures.

1.5 . When calculating structures, one should take into account the reliability coefficients UD, adopted in accordance with the Rules for taking into account the degree of responsibility of buildings and structures when designing structures. approved by the USSR State Construction Committee.

1.6. When designing buildings and structures, measures should be taken to ensure the possibility of their construction in winter conditions.

Reinforced stone structures

4.30. Calculation of elements with mesh reinforcement (Fig. 10) under central compression should be made according to the formula

where is the calculated longitudinal force;

Design resistance under central compression, determined for reinforced masonry made of bricks of all types and ceramic stones with slot-like vertical voids according to the formula

when the strength of the mortar is less than 2.5 MPa (25 kgf), when checking the strength of the masonry during its construction according to the formula

![]() .

(28)

.

(28)

If the strength of the solution is more than 2.5 MPa (25 kgf/), the ratio is taken equal to 1;

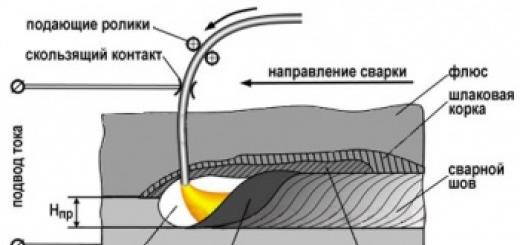

Rice. 10. Transverse (mesh) reinforcement

stone structures

Reinforcement mesh;

- release of reinforcement

grids to control its placement

Calculated compressive resistance of unreinforced masonry during the considered period of mortar hardening;

Design resistance of masonry with mortar grade 25;

Percentage of reinforcement by volume, for meshes with square cells made of reinforcement with a cross-section of the cell size at a height distance between marks

Coefficient determined by formula (16);

And - respectively, the volumes of reinforcement and masonry;

Buckling coefficient determined from table. 18 for or with the elastic characteristics of masonry with mesh reinforcement, determined by formula (4).

![]() .

.

2. Elements with mesh reinforcement are made using mortar grades of at least 50 with a masonry row height of no more than 150 mm.

4.31. Calculation of eccentrically compressed elements with mesh reinforcement at small eccentricities that do not extend beyond the core of the section (for rectangular section), should be produced according to the formula

![]() ,

(29)

,

(29)

or for rectangular section

![]() ,

(30)

,

(30)

where is the design resistance of reinforced masonry under eccentric compression, determined with a mortar grade of 50 and higher according to the formula

![]() ,

(31)

,

(31)

and when the grade of mortar is less than 25 (when checking the strength of the masonry during its construction) according to the formula

![]() .

(32)

.

(32)

The remaining quantities have the same meanings as in paragraphs. 4.1. and 4.7.

Notes 1. For eccentricities beyond the core of the section (for rectangular sections), as well as for or, mesh reinforcement should not be used.

2. The percentage of masonry reinforcement with mesh reinforcement during eccentric compression should not exceed that determined by the formula

![]() .

.

5. CALCULATION OF STRUCTURE ELEMENTS ACCORDING TO LIMITS

CONDITIONS OF THE SECOND GROUP (ON EDUCATION AND DISCLOSURE

CRACKS AND DEFORMATIONS)

5.1. Based on the formation and opening of cracks (masonry joints) and deformations, the following should be calculated:

a) eccentrically compressed unreinforced elements with

b) adjacent, working together structural elements of masonry from materials of different deformability (with different moduli of elasticity, creep, shrinkage) or with a significant difference in the stresses arising in these elements;

c) self-supporting walls connected to frames and working in transverse bending, if the load-bearing capacity of the walls is insufficient to independently (without a frame) bear loads;

d) wall fillings of frames - for distortion in the plane of the walls;

e) longitudinally reinforced bending, eccentrically compressed and tensile elements operated in environments that are aggressive to reinforcement;

f) longitudinally reinforced containers if there are requirements for the impermeability of plaster or tile insulating coatings;

g) other elements of buildings and structures in which the formation of cracks is not allowed or the opening of cracks must be limited due to operating conditions.

5.2. Calculation of masonry and reinforced masonry structures according to the limit states of the second group should be carried out for the influence of standard loads for their main combinations.

5.3. Calculation of the opening of cracks (masonry joints) of eccentrically compressed unreinforced masonry structures should be carried out at , based on the following provisions:

in the calculation, a linear diagram of eccentric compression stresses is taken as for an elastic body;

the calculation is made using the conditional tensile edge stress, which characterizes the magnitude of crack opening in the tensile zone.

The calculation should be made according to the formula

![]() ,

(33)

,

(33)

where is the moment of inertia of the section in the plane of action of the bending moment;

The distance from the center of gravity of the section to its compressed edge;

Calculated tensile strength of masonry during bending along an untied section (see Table 10);

Coefficient of masonry operating conditions when calculating crack opening, taken according to table. 24.

The remaining designations of quantities are the same as in paragraph 4.7.

Table 24

|

Characteristics and working conditions of masonry |

Coefficient of operating conditions for the expected service life of structures, years |

||

|

1. Unreinforced eccentrically loaded and tensioned masonry |

|||

|

2. The same, with decorative finishing for structures with increased architectural requirements |

|||

|

3. Unreinforced eccentrically loaded masonry with waterproofing plaster for structures operating under hydrostatic fluid pressure |

|||

|

4. The same, with acid-resistant plaster or cladding on liquid glass putty |

|||

|

Note. The coefficient of operating conditions when calculating longitudinally reinforced masonry for eccentric compression, bending, axial and eccentric tension and main tensile stresses is taken according to table. 24 with odds: 1.25 at ; 1 at . For intermediate percentages of reinforcement - by interpolation performed according to the formula |

|||

5.4. Structures in which, due to operating conditions, the appearance of cracks in plaster and other coatings cannot be allowed, must be checked for deformation of tensile surfaces. These deformations for unreinforced masonry should be determined at standard loads that will be applied after applying plaster or other coatings, according to formulas (34) - (37). They should not exceed the values of relative deformations given in table. 25.

Table 25

|

Type and purpose of coatings |

|

|

Waterproofing cement plaster for structures subject to hydrostatic pressure of liquids |

|

|

Acid-resistant plaster on liquid glass or a single-layer coating of cast stone tiles (diabase, basalt) on acid-resistant putty |

|

|

Two- and three-layer coatings of rectangular stone cast tiles with acid-resistant putty: |

|

|

a) along the long side of the tiles |

|

|

b) the same, along the short side of the tiles |

|

|

Note. When longitudinally reinforcing structures, as well as when plastering unreinforced structures on a grid, the maximum relative deformations can be increased by 25%. |

|

5.5. Calculation of deformations of tensile surfaces of stone structures made of unreinforced masonry should be carried out using the formulas:

with axial tension

when bending

with eccentric compression

(36)

(36)

with eccentric tension

(37)

(37)

In formulas (34) - (37):

And - longitudinal force and moment from standard loads that will be applied after applying plaster or tile coatings to the masonry surface;

Limit relative deformations accepted according to table.

25;

Distance from the center of gravity of the masonry section to the most distant stretched edge of the covering;

Section moment of inertia;

The deformation modulus of the masonry, determined by formula (8).

6. GUIDELINES FOR STRUCTURE DESIGN

General instructions

6.1. When checking the strength and stability of walls, pillars, cornices and other elements during the construction of buildings, it should be taken into account that the floor elements (beams, slabs, etc.) are laid along the course of the masonry and that it is possible to support the building elements on fresh masonry.

6.2. Large-sized structural elements (panels, large blocks, etc.) must be checked by calculation for the stages of their manufacture, transportation and installation. The dead weight of elements of prefabricated structures should be taken into account taking into account the dynamic coefficient, the value of which is taken to be equal to: during transportation - 1.8; during lifting and installation - 1.5; in this case, the overload coefficient to the element’s own weight is not entered. It is allowed to reduce the above dynamic coefficients if this is confirmed by long-term experience in the use of such elements, but not lower than 1.25.

6.3. For continuous masonry of regularly shaped stones, with the exception of brick panels, the following minimum bonding requirements must be provided:

a) for masonry made of solid brick 65 mm thick - one joint row for six rows of masonry, and for brick 88 mm thick and hollow brick 65 mm thick - one joint row for four rows of masonry;

6.4. It is necessary to protect walls and pillars from moisture from the side of the foundations, as well as from adjacent sidewalks and blind areas by installing a waterproofing layer above the level of the sidewalk or top of the blind area.

The waterproofing layer should also be installed below the basement floor.

For window sills, belts, parapets and similar protruding parts of the walls that are especially susceptible to moisture, protective coatings made of cement mortar, roofing steel, etc. should be provided. The protruding parts of the walls must have slopes that ensure the drainage of atmospheric moisture.

6.5. Non-reinforced masonry made of stone materials, depending on the type of masonry, as well as the strength of stones and mortars, are divided into four groups (Table 26).

|

Table 26(K) |

Type of masonry |

|||

|

Masonry group |

1. Solid masonry made of bricks or stones of grade 50 and higher |

With a solution of grade 10 and higher |

||

|

With grade 4 solution |

1. Solid masonry made of bricks or stones of grade 50 and higher |

With a solution of grade 10 and higher |

||

|

2. The same, stamps 35 and 25 |

3. The same, stamps 15, 10 and 7 |

3. The same, stamps 15, 10 and 7 |

||

|

On any solution |

||||

|

4. The same, brand 4 |

5. Large blocks of brick or stones (vibrated and non-vibrated) |

|||

|

On a solution of grade 25 and higher |

6. Masonry from soil materials (soil blocks and mud bricks) |

On lime mortar |

||

|

On clay mortar |

7. Lightweight masonry of brick or concrete stones tied with horizontal bonded rows or staples |

On mortar grade 50 and higher, filled with concrete grade not lower than M 25 or with liners grade 25 and higher |

On mortar grade 25 filled with concrete or liners grade 15 |

|

|

Using grade 10 mortar and filling with backfill |

8. Lightweight brick or stone masonry for wells (with ligation of vertical diaphragms) |

On mortar grade 50 and higher, filled with thermal insulation boards or backfill |

||

|

Using grade 25 mortar filled with thermal insulation boards or backfill |

5. Large blocks of brick or stones (vibrated and non-vibrated) |

9. Masonry made of rubble |

On lime mortar |

|

|

On a solution of grades 10 and 4 |

10. Masonry made of torn rubble |

With a solution of grade 50 and higher |

With a solution of grade 10 and higher |

|

|

On a solution of grades 25 and 10 |

11. Rubble concrete |

On concrete grade B7.5 and higher |

On concrete grades B5 and B3.5 |

|

On concrete grade B2.5

6.6. Stone walls, depending on the structural design of the building, are divided into:

load-bearing, in addition to loads from their own weight and wind, also loads from coatings, ceilings, cranes, etc.;

non-load-bearing (including hinged), taking the load only from its own weight and wind within one floor with a floor height of no more than 6 m; with a higher floor height, these walls are self-supporting;

partitions - internal walls that absorb loads only from their own weight and wind (with open window openings) within one floor, with a height of no more than 6 m; with a higher floor height, walls of this type are conventionally classified as self-supporting.

In buildings with self-supporting and non-load-bearing external walls, loads from coatings, ceilings, etc. transferred to the frame or transverse structures of buildings.

6.7. When calculating for horizontal loads, eccentric and central compression, stone walls and pillars of buildings should be assumed to be supported in the horizontal direction on interfloor floors, coverings and transverse walls. These supports are divided into rigid (non-displaceable) and elastic.

The following should be taken as rigid supports:

a) transverse stone and concrete walls with a thickness of at least 12 cm, reinforced concrete with a thickness of at least 6 cm, buttresses, transverse frames with rigid joints, sections of transverse walls and other structures designed to bear horizontal loads;

b) coverings and interfloor ceilings with a distance between transverse, rigid structures not exceeding those indicated in the table. 27;

c) wind belts, trusses, wind ties and reinforced concrete frames, calculated in terms of strength and deformation to accommodate the horizontal load transmitted from the walls.

Coverings and interfloor ceilings should be taken as elastic supports when the distances between transverse rigid structures exceed those indicated in the table.

27, in the absence of wind connections specified in subparagraph “c”.

Walls and pillars that are not connected to the floors (when installing roller supports, etc.) should be considered free-standing.

|

Table 27 |

Type of coatings and floors |

|||

|

Distance between transverse rigid structures, m, with masonry group |

||||

|

A. Prefabricated reinforced concrete cast-in-place (see note 2) and monolithic |

||||

|

B. From precast concrete decks (see note 3) and from reinforced concrete or steel beams with slab or stone decking |

||||

|

B. Wooden Notes: 1. Indicated in table. 27 maximum distances must be reduced in the following cases: a) at wind speeds of 70, 85 and 100 kgf/ respectively by 15, 20 and 25%; c) for narrow buildings with a width less than twice the height of the floor - proportional to the ratio. 2. In prefabricated cast-in-place floors of type A, the joints between the slabs must be strengthened to transmit tensile forces through them (by welding reinforcement outlets, laying additional reinforcement in the seams with filling the seams with a mortar of a grade not lower than 100 - for slabs made of heavy concrete and a grade not lower than M 50 - with slabs made of lightweight concrete or other methods of embedding). 3. In type B floors, the seams between slabs or stones, as well as between filling elements and beams, must be carefully filled with a solution of a grade of at least 50. 4. Type B floors must have double wooden flooring or flooring, bevel and hemming. |

||||

6.8. With elastic supports, a frame system is calculated, the racks of which are walls and pillars (reinforced concrete, brick, etc.), and the crossbars are floors and coverings. In this case, it should be assumed that the racks are rigidly clamped in the supporting sections.

In static calculations of frames, the rigidity of walls or pillars made of brick or stone masonry can be determined using the modulus of elasticity of the masonry and the moment of inertia of the section without taking into account the opening of the seams, and the ceilings and coverings should be taken as rigid crossbars (spacers) hingedly connected to the walls.

6.9. In walls with or without pilasters, the width of the wall when calculating should be taken as follows:

a) if the design of the covering ensures uniform transmission of pressure along the entire length of its support on the wall, equal to the width between the openings, and in walls without openings, equal to the width of the section of the wall between the axes of the spans;

b) if the lateral pressure from the wall to the covering is transferred in places where trusses or purlins rest on the walls, then the wall with a pilaster is considered as a frame post with a constant cross-section in height, while the width of the shelf is assumed to be equal in each direction from the edge of the pilaster, but no more the width of the wall between the openings ( - the height of the wall from the embedment level, - the thickness of the wall). In the absence of pilasters and the transfer of concentrated loads to the walls, the width of the section is taken in each direction from the edge of the distribution slab installed under the supports of the trusses or purlins.

6.10. Walls and pillars that have supports in the planes of interfloor floors, considered as rigid according to clause 6.7, are designed for eccentric loads as vertical continuous beams.

It is permissible to consider walls or pillars divided in height into single-span beams with support hinges located in the planes of support of the floors.

In this case, the load from the upper floors should be taken to be applied at the center of gravity of the section of the wall or pillar of the overlying floor; loads within the calculated floor are taken to be applied with actual eccentricities relative to the center of gravity of the section of the wall or pillar, taking into account the change in the section within the floor and weakening by horizontal and inclined grooves. In the absence of special supports that fix the position of the support pressure, it is allowed to take the distance from the point of application of the support reaction of purlins, beams or flooring to the inner edge of the wall or base plate equal to one third of the embedment depth, but not more than 7 cm.

Bending moments from wind loads should be determined within each floor as for a beam with embedded ends, with the exception of the upper floor, in which the upper support is assumed to be hinged.

6.11. When calculating walls (or their individual vertical sections) for vertical and horizontal loads, the following must be checked:

a) horizontal sections in compression or eccentric compression;

b) inclined sections for the main tensile stresses during bending in the plane of the wall;

c) opening of cracks from the vertical load of differently loaded, interconnected walls or different rigidities of adjacent sections of walls.

![]() ,

(38)

,

(38)

When taking into account the joint work of transverse and longitudinal walls under the action of a horizontal load, the perception of shear forces in the places of their mutual abutment, determined by the formula, must be ensured

where is the shear force within one floor;

Design shear force from horizontal load at the middle of the floor height;

The distance from the axis of the longitudinal wall to the axis passing through the center of gravity of the wall section in plan (Fig. 11);

Rice. 11. Plan of the transverse wall and piers of the longitudinal walls

Longitudinal wall pier;

- transverse wall

Sectional area of the shelf (section of the longitudinal wall taken into account in the calculation);

Moment of inertia of the wall section relative to an axis passing through the center of gravity of the wall section in plan;

Transverse wall thickness;

Floor height;

6.12. Calculation of transverse walls for main tensile stresses should be made according to the formula

if there is a stretched part of the section in the wall - according to the formula

In formulas (39) and (40):

Design shear force from horizontal load at mid-height of floor

![]() ,

(41)

,

(41)

Calculated resistance to main tensile stresses at masonry joints (Table 10);

Design resistance to shearing of masonry, compressed by design force, determined with an overload coefficient of 0.9;

If there is a stretched part of the section in the wall, it is accepted

where is the cross-sectional area of the transverse wall, taking into account (or not taking into account) sections of the longitudinal wall (see Fig. 11);

The area of only the compressed part of the wall section, with eccentricities extending beyond the core of the section;

The thickness of the transverse wall in the area where this thickness is the smallest, provided that the length of this area exceeds 1/4 of the floor height or 1/4 of the wall length; if there are channels in the wall, their width is excluded from the wall thickness;

The length of the transverse wall in plan, if the section includes shelves in the form of segments of external walls, then - the distance between the axes of these shelves;

Coefficient of unevenness of tangential stresses in a section. Values allowed:

for I-sections,

for T-sections,

for rectangular sections (without taking into account the work of longitudinal walls);

The static moment of the part of the section located on one side of the axis passing through the center of gravity of the section;

The moment of inertia of the entire section relative to an axis passing through the center of gravity of the section.

6.13. If the masonry has insufficient resistance to chipping, determined by formulas (39), (40), it is allowed to reinforce it with longitudinal reinforcement in horizontal joints. The design resistance to shearing of reinforced masonry should be determined using the formula

![]() ,

(44)

,

(44)

where is the percentage of reinforcement determined by the vertical section of the wall.

6.14. When calculating the transverse walls of a building for horizontal loads acting in their plane, lintels covering openings in the walls are considered as hinged inserts between the vertical sections of the walls.

If the strength of transverse walls with openings under the action of horizontal loads is ensured only taking into account the rigidity of the lintels, then the lintels must absorb the shear forces occurring in them, determined by the formula

where is the calculated transverse force from the horizontal load, perceived by the transverse wall at the level of the floor adjacent to the calculated lintels;

Moment of inertia of the wall section relative to an axis passing through the center of gravity of the wall section in plan;

Length of the transverse wall in plan (clause 6.12);

Accepted according to clause 6.12.

6.15. The calculation of jumpers for shearing force from a horizontal load, determined by formula (45), is carried out for shearing and bending according to formulas (46) and (47), and the smaller of the two obtained values is accepted

where and are the height and span of the lintel (clear);

See formula (45);

Cross section of the lintel;

And - see table. 10.

If the strength of the lintels is insufficient, then they must be reinforced with longitudinal reinforcement or reinforced concrete beams designed for bending and shearing at the moment

and shear force, formula (45), in accordance with the chapter of SNiP on the design of concrete and reinforced concrete structures. Calculation of the sealing of the ends of beams (lintels) in the masonry is carried out according to the instructions in clause 6.46.

Acceptable ratios of heights of walls and pillars

to their thickness

6.16. The ratio of the height of a wall or pillar to its thickness, regardless of the calculation results, should not exceed those specified in paragraphs. 6.17 - 6.20.

6.17. The ratio (where is the height of the floor, is the thickness of the wall or the smaller side of the rectangular section of the column) for walls without openings bearing loads from floors or coverings, with the free length of the wall should not exceed the values given in table. 28 (for masonry made of stone materials of regular shape).

Table 28

|

Brand of solution |

Relationships with masonry group (see table 26) |

|||

For walls with pilasters and pillars of complex cross-section, the conventional thickness is used instead, where .

For pillars of round and polygonal sections inscribed in a circle, , where is the cross-sectional diameter of the pillar.

Note. If the floor height is greater than the free length of the wall, the ratio should not exceed 1.2 according to the table. 28.

6.18. Ratios for walls and partitions under conditions different from those specified in clause 6.17 should be accepted with the correction factor given in table. 29.

|

Table 29 |

Characteristics of walls and partitions |

|

Coefficient |

|

|

1.Walls and partitions that do not bear loads from floors or coatings with a thickness, cm: |

|

|

25 or more |

|

|

10 or less |

|

|

2. Walls with openings |

|

|

3. Partitions with openings |

|

|

4. Walls and partitions with their free length between adjacent transverse walls or columns from 2.5 to 3.5 |

|

|

5. The same, with |

|

|

6. Walls made of rubble masonry and rubble concrete 2. If the thickness of non-load-bearing walls and partitions is more than 10 and less than 25 cm, the value of the correction factor is determined by interpolation. 3. The values - net area and - gross area are determined by the horizontal section of the wall. |

|

Limit ratios for pillars are taken according to table. 28 with the coefficients given in table. thirty.

Table 30

|

Coefficient for pillars |

||

|

Smaller cross-sectional size of the pillar, cm |

made of bricks and stones of regular shape |

from rubble masonry and rubble concrete |

|

90 or more |

||

|

0.6, the height of the walls is not limited and is determined by strength calculations. With a free length equal to or greater than , but not more (where is the floor height), the condition must be met 6.20. For walls, partitions and pillars that are not fixed in the upper section, the ratio values should be 30% less than those established in paragraphs 6.17 - 6.19. Walls made of panels and large blocks 6.21. Brick panels should be designed from clay or sand-lime brick of a grade of at least 75 in mortar grades of at least 50. 6.22. When designing panels, it should, as a rule, provide for filling mortar joints using vibration. The calculated resistance of the vibrating masonry should be taken according to clause 3.2. It is allowed to design single-layer panels of external walls from hollow ceramic stones that are thermally efficient, one, one and a half and two stones thick without the use of vibration. In this case, the calculated resistance of the masonry should be taken according to clause 3.1. Note. In panels made of hollow ceramic stones made without the use of vibration, the ligation of the vertical joints of the masonry must be observed, which must be indicated in the project. 6.23. Brick panels of external walls should be designed as two-layer or three-layer. Two-layer panels should be made with a thickness of half a brick or more with insulation from rigid heat-insulating boards located on the outer or inner side of the panels and protected by a finishing reinforced layer of mortar of a grade of at least 50, with a thickness of at least 40 mm. Three-layer panels should be made with outer layers a quarter or half a brick thick and a middle layer of rigid or semi-rigid thermal insulation boards. When designing external wall panels, it should be taken into account that, depending on the architectural requirements, the outer layer of the panels can be made with an open texture of brick and stones or with a finishing layer of mortar. 6.24. Brick panels of internal walls and partitions should be designed single-layer thick: a quarter of a brick (8.5 cm), half a brick (14 cm) and a brick (27 cm) and two-layer of two layers of a quarter brick thick (18 cm). Frames in panels of internal walls should be installed along the perimeter of the panels along the contour of the openings. Notes: 1. Panel thicknesses are indicated taking into account the outer and inner mortar layers. 2. Panels one-quarter brick thick should be designed for partition walls only. 6.25. Brick and ceramic wall panels should be designed for eccentric compression according to the instructions given in paragraphs. 4.7 and 4.8 under the action of vertical and wind loads, as well as the forces arising during transportation and installation (see clause 6.2). If the required strength of the panel is ensured without taking into account the reinforcement, then the cross-sectional area of the longitudinal rods of the frames should be determined from the condition that it be at least 0.25 cm per meter of horizontal and vertical sections of the panel. If reinforcement must be taken into account when determining the load-bearing capacity of a panel, then it should be calculated as for a reinforced masonry structure. When calculating panels with a thickness of 27 cm or less, random eccentricity should be taken into account, the value of which is taken to be 1 cm for load-bearing single-layer panels; 0.5 cm - for self-supporting panels, as well as for individual layers of three-layer load-bearing panels; For non-structural panels and partitions, random eccentricity is not taken into account. 6.26. Panels with reinforced ribs different materials 6.27. Connections between external and internal wall panels, as well as external wall panels and floor panels should be designed using steel ties welded to embedded parts or to frame plates. The connections between the panels must be installed in recesses located in the corners of the panels and covered with a layer of mortar at least 10 mm thick. When making embedded parts and connecting rods from ordinary steel, they must be protected from corrosion. The grade of mortar for installation joints of panel walls should be taken according to calculation, but not less than 50. 6.28. Large blocks for external and internal walls should be designed from cement and silicate heavy concrete, concrete on porous aggregates, cellular concrete and natural stone, as well as from masonry made from brick, ceramic, concrete and natural stones. The calculated resistance of masonry made from large blocks is taken according to paragraph 3.3, and for blocks made of brick or stones without vibration - according to paragraphs. 3.1, 3.4 and 3.6. The grade of mortar for installation joints of masonry blocks made of bricks or stones should be taken one step higher than the grade of mortar of blocks. 6.29. In large-block buildings with a height of up to 5 floors inclusive, with a floor height of up to 3 m, the connection between the longitudinal and transverse walls should be carried out: a) in the outer corners - by bandaging the masonry with special corner blocks (at least one row of blocks per floor); b) in the places where the internal transverse walls adjoin the longitudinal ones, as well as the middle longitudinal wall and the end walls - by laying T-shaped anchors made of strip steel or reinforcing mesh in one horizontal seam in each floor at the floor level. For large-block buildings with a height of more than 5 floors and for buildings with a floor height of more than 3 m, rigid connections must be provided between the walls, both in the corners and in the places where the internal walls adjoin the external ones. Connections should be designed in the form of embedded parts in blocks, connected by welding to overlays. Multilayer walls (lightweight walls masonry and walls with cladding) 6.30. When calculating multilayer walls (see paragraphs 4.21 - 4.29), the connections between the structural layers should be considered rigid: a) for any heat-insulating layer and the distances between the axes of vertical diaphragms from interlocking rows of bricks or stones are no more than 10 and no more than 120 cm, where is the thickness of the thinner structural layer; b) with a heat-insulating layer of monolithic concrete with a compressive strength of at least 0.7 MPa (7 kgf/) or with masonry made of stones of a grade of at least 10, with horizontal bonded rows located at distances between the axes of the rows along the height of the masonry of no more 5 and no more than 62 cm. 6.31. Flexible connections should be designed from corrosion-resistant steels or steels protected from corrosion, as well as from polymeric materials. The total cross-sectional area of flexible steel ties must be at least 0.4 per 1 wall surface. 6.32. The facing layer and the main masonry of the wall, if they are rigidly connected to each other by mutual ligation, should, as a rule, have similar deformation properties. It is recommended to provide for the use facing bricks or stones having a height equal to the height of the main masonry row. 6.33. Projects should include ligation of cladding rigidly connected to the masonry with bonded rows, according to the instructions in clause 6.3. 6.34. When installing edges in masonry rigidly connected to the cladding, within the protruding part of the wall along its entire thickness, the design should provide for laying reinforcing mesh at the edge in at least three seams. Anchoring of walls and pillars 6.35. Stone walls and pillars must be attached to floors and coverings with anchors with a cross-section of at least 0.5. 6.36. The distance between the anchors of beams, purlins or trusses, as well as floors made of prefabricated decking or panels resting on walls, should be no more than 6 m. When increasing the distance between trusses to 12 m, additional anchors should be provided connecting the walls with the covering. The ends of beams laid on purlins, internal walls or pillars must be anchored and connected to each other when supported on both sides. 6.37. Self-supporting walls in frame buildings must be connected to columns with flexible connections that allow for independent vertical deformations of walls and columns. The connections installed along the height of the columns must ensure the stability of the walls, as well as the transfer of the wind load acting on them to the frame columns. 6.38. Calculation of anchors should be made: a) with a distance between anchors of more than 3 m; b) with an asymmetrical change in the thickness of a pillar or wall; c) for piers with a total normal force of more than 1000 kN (100 t).

where is the bending moment from the design loads at the level of the ceiling or covering (see clause 6.10) in places where they rest on the wall at a width equal to the distance between the anchors (Fig. 12); Moment of inertia of the wall section relative to an axis passing through the center of gravity of the wall section in plan; The calculated normal force at the anchor level at a width equal to the distance between the anchors.

Rice. 12. Determination of the force in the anchor from the bending moment at the floor level Note. The instructions of this paragraph do not apply to walls made of vibrating brick panels. 6.39. If the thickness of walls or partitions is determined taking into account the support along the contour, it is necessary to provide for their fastening to the adjacent side structures and to the upper floor. Supporting structural elements on masonry 6.40. Under the supporting sections of elements that transfer local loads to the masonry, a layer of mortar no more than 15 mm thick should be provided, which should be specified in the design. 6.41. In places where local loads are applied, in cases where this is required by calculations for crushing, it is necessary to provide for the installation of distribution slabs with a thickness that is a multiple of the thickness of the masonry rows, but not less than 15 cm, reinforced according to the calculation with two meshes with a total amount of reinforcement of at least 0.5% of the volume concrete. 6.42. When supporting trusses, roof beams, crane beams, etc. on pilasters, it is necessary to provide a connection between the distribution slabs on the supporting section of the masonry and the main wall. The depth of embedding of slabs into the wall should be at least 12 cm (Fig. 13).

The masonry located above the slabs should be carried out immediately after the installation of the slabs. It is not allowed to install slabs in grooves left when laying walls. Rice. 13. Reinforced concrete distribution slabs 6.43. For local edge loads exceeding 80% of the design bearing capacity of the masonry under local compression, it is necessary to provide for reinforcement of the supporting section of the masonry with meshes of rods with a diameter of at least 3 mm with a cell size of no more than 60x60 mm, laid in at least three upper horizontal seams. When transferring local loads to pilasters, the masonry section located within 1 m below the distribution slab should be reinforced across three rows of masonry with the meshes specified in this paragraph. The grids must connect the supporting sections of the pilasters with the main part of the wall and be embedded in the wall to a depth of at least 12 cm. 6.44. When resting reinforced concrete purlins, beams and decks on brick walls and pillars, in addition to the calculation for eccentric compression and crushing of the sections below the support unit, the cross-section of the masonry and reinforced concrete elements must be checked for central compression. The calculation of the support unit under central compression should be made according to the formula where is the total cross-sectional area of the masonry and reinforced concrete elements in the support unit within the contour of the wall or pillar on which the elements are laid; A coefficient that depends on the size of the support area of reinforced concrete elements in a node; A coefficient depending on the type of voids in a reinforced concrete element. Taken equal to: for solid elements and floorings with round voids - 1; for floorings with oval voids and the presence of clamps on the supporting areas - 0.5. 6.45. In precast reinforced concrete decks with unfilled voids, in addition to checking the load-bearing capacity of the support unit as a whole, the load-bearing capacity of the horizontal section intersecting the ribs of the deck must be checked according to the formula

where is the design resistance of concrete to axial compression, taken in accordance with the chapter of SNiP for the design of concrete and reinforced concrete structures; The horizontal cross-sectional area of the deck, weakened by voids, over the length of the deck supporting the masonry (total cross-sectional area of the ribs); Design compressive resistance of masonry; from the plane of the wall. The required embedment depth should be determined using the formula

If the embedding of the end of the beam does not satisfy the calculation according to formula (53), then the embedment depth should be increased or distribution pads should be placed under and above the beam. If the eccentricity of the load relative to the center of the embedment area exceeds more than 2 times the embedment depth (), compression stresses may not be taken into account: the calculation in this case is made according to the formula When using distribution pads in the form of narrow beams with a width of no more than 1/3 of the embedment depth, it is allowed to take a rectangular stress diagram under them (Fig. 14,).

Rice. 14. Calculation schemes for embedding cantilever beams Lintels and hanging walls 6.47. Reinforced concrete lintels should be designed for the load from the floors and the pressure from freshly laid, uncured masonry, equivalent to the weight of a masonry belt with a height equal to 1/3 of the span for masonry in summer conditions and the whole span for masonry in winter conditions (in the thawing stage). Notes: 1. It is allowed, in the presence of appropriate design measures (protrusions in prefabricated lintels, reinforcement outlets, etc.), to take into account the joint work of the masonry with the lintel. 2. Loads on lintels from beams and floor decks are not taken into account if they are located above a square of masonry with a side equal to the span of the lintel, and in the case of thawing masonry made by freezing - above a rectangle of masonry with a height equal to twice the clear span of the lintel. When the masonry thaws, the lintels can be strengthened by installing temporary supports on wedges for the period of thawing and initial hardening of the masonry. 3. In the vertical seams between the timber lintels, in cases where the required resistance to their heat transfer is not provided, provision should be made for laying insulation. 6.48. The masonry of hanging walls supported by rund beams should be tested for crushing strength in the area above the rund beam supports. The strength of the masonry when crushed under the supports of the rand beams must also be checked.

The length of the pressure distribution diagram in the plane of contact between the wall and the rand beam should be determined depending on the rigidity of the masonry and the rand beam. In this case, the rand beam is replaced by a conditional masonry belt equivalent in rigidity, the height of which is determined by the formula where is the initial modulus of elasticity of concrete; The moment of inertia of the reduced section of the rand beam, taken in accordance with the chapter of SNiP for the design of concrete and reinforced concrete structures; The deformation modulus of the masonry, determined by formula (7); Thickness of hanging wall. | ||

The stiffness of steel rand beams is determined as the product

Stone materials are classified: by origin: a) natural stones mined in stone quarries (stone blocks, rubble); b) artificial stones produced by firing (brick, ceramic stones), and unfired stones (silicate brick, slag brick, concrete stones made of heavy and light concrete); by structure: a) solid brick and solid stones; b) hollow bricks and stones with voids of various shapes.

For manual masonry, the following types of bricks are used: ordinary ceramic plastic and semi-dry pressing, hollow ceramic plastic pressing, silicate brick, brick made of tripoli and diatomite.

Solid ceramic and sand-lime bricks are used for masonry load-bearing walls and pillars; ceramic hollow - for laying external walls of heated buildings. Ceramic and concrete stones are used in the construction of walls and partitions, and large blocks of heavy concrete are also used for laying foundation walls.

Natural stones from heavy rocks (limestone, sandstone, granite) are used mainly for cladding walls and laying foundations, and in some areas walls are built from light rocks (tuff, limestone, shell rock).

The main characteristic of stone materials used in load-bearing structures is their strength, characterized by a grade that indicates the temporary resistance of the samples under compression.

Fittings. For the reinforcement of stone structures, the following should be used: as mesh reinforcement - hot-rolled round steel of class A-1 or reinforcing wire of a periodic profile of class VR-1 with a diameter of 3...8 mm, as longitudinal and transverse reinforcement - steel of classes A-1, A -11 and Vr-1 with a diameter of 5...8 mm. Connecting elements, embedded parts and steel frames should be made from rolled sheet steel, shaped profiles, and strip steel.

Calculation of stone and reinforced masonry structures is carried out using the limit state method. In this case, 2 groups of limit states are taken into account: the first for bearing capacity (strength and stability), the second for the formation and opening of cracks (masonry joints) and deformations. Calculations according to the first group are always performed for all types of structures. Calculations in the second group are carried out for structures where cracks are not allowed (tank linings) or their incomplete opening is required (eccentrically compressed elements with large eccentricities), deformations are limited according to the conditions of joint operation of adjacent structures (wall fillings of building frames), etc. The purpose of the calculation is to selecting sections of elements or checking existing sections. The calculated stresses, deformations and crack widths should not exceed the limit values established by the standards.

The calculation for bearing capacity is made from the condition that the design force N is less than or equal to the design bearing capacity. The design force is calculated under the action of loads taken with a safety factor under their unfavorable combination. The design load-bearing capacity is determined depending on the geometric dimensions of the section, the design resistance of the masonry R and the operating conditions coefficients. The calculated resistance, which takes into account the possibility of a decrease in strength associated with the natural variation in mechanical properties, is taken into account by the reliability coefficient and is determined by the formula

SNiP II-22-81

BUILDING REGULATIONS

STONE AND REINFORCED STONE STRUCTURES

Date of introduction 1983-01-01

DEVELOPED by the Central Research Institute of Building Structures (TSNIISK) named after. V.A. Kucherenko State Construction Committee of the USSR.

INTRODUCED by TsNIISK them. Kucherenko Gosstroy USSR

APPROVED by Decree of the USSR State Committee for Construction Affairs dated December 31, 1981 No. 292

With the entry into force of this chapter of SNiP, chapter SNiP II-B.2-71 “Masonry and reinforced masonry structures. Design standards” is cancelled.

SNiP II-22-81 “Stone and reinforced stone structures” was amended, approved by Decree of the USSR State Construction Committee dated September 11, 1985 N 143 and put into effect on January 1, 1986. The paragraphs and tables to which changes were made are noted in these Building code sign (K).

The changes were made by the legal bureau "Code" according to the official publication (Ministry of Construction of Russia - State Enterprise TsPP, 1995).

1. GENERAL PROVISIONS

1.1. The standards of this chapter must be observed when designing masonry and reinforced masonry structures of new and reconstructed buildings and structures.

1.2. When designing stone and reinforced masonry structures, the following design solutions, products and materials should be used:

a) external walls made of: hollow ceramic and concrete stones and bricks; lightweight brickwork with slab insulation or backfill made of porous aggregates; solid stones and concrete blocks on porous aggregates, porous and cellular concrete. The use of solid masonry made of solid clay or silicate bricks for the external walls of rooms with dry and normal humidity conditions is allowed only if it is necessary to ensure their strength;

b) walls made of panels and large blocks made of concrete various types, as well as from brick or stones;

c) bricks and stones of grades with a compressive strength of 150 or more in buildings with a height of more than five floors;

d) local natural stone materials;

e) solutions with antifreeze chemical additives for winter masonry, taking into account the instructions of Section. 7.

Note. With appropriate justification, it is allowed to use design solutions, products and materials not provided for in this paragraph.

1.3. Application of silicate bricks, stones and blocks; stones and blocks made of cellular concrete; hollow bricks and ceramic stones; semi-dry pressed clay bricks are allowed for external walls of rooms with wet conditions, provided that a vapor barrier coating is applied to their internal surfaces. The use of these materials for the walls of rooms with wet conditions, as well as for the external walls of basements and plinths, is not allowed. The humidity conditions of the premises should be taken in accordance with the chapter of SNiP on construction heating engineering.

1.4. The strength and stability of structures and their elements must be ensured during construction and operation, as well as during transportation and installation of elements of prefabricated structures.

1.5. When calculating structures, one should take into account the reliability coefficients adopted in accordance with the Rules for taking into account the degree of responsibility of buildings and structures when designing structures, approved by the USSR State Construction Committee.

1.6. When designing buildings and structures, measures should be taken to ensure the possibility of their construction in winter conditions.

2. MATERIALS

2.1(K). Brick, stones and mortars for stone and reinforced stone structures, as well as concrete for the manufacture of stones and large blocks must meet the requirements of the relevant GOSTs and be used in the following grades or classes:

a) stones - according to compressive strength (and brick - for compressive strength taking into account its bending strength): 4, 7, 10, 15, 25, 35, 50 (low-strength stones - light concrete and natural stones); 75, 100, 125, 150, 200 (medium strength - brick, ceramic, concrete and natural stones); 250, 300, 400, 500, 600, 800, 1000 (high strength - brick, natural and concrete stones);

b)(K) concrete classes according to compressive strength:

heavy - B3.5; AT 5; B7.5; B12.5; B15; IN 20; B25; B30;

on porous fillers - B2; B2.5; B3.5; AT 5; B7.5; B12.5; B15; IN 20; B25; B30;

cellular - B1; AT 2; B2.5; B3.5; AT 5; B7.5; B12.5;

large-porous - B1; AT 2; B2.5; B3.5; AT 5; B7.5;

porous - B2.5; B3.5; AT 5; B7.5;

silicate - B12.5; B15; IN 20; B25; B30.

It is allowed to use concrete as insulation materials whose compressive strength limits are 0.7 MPa (7 kgf/) and 1.0 MPa (10 kgf/); and for liners and slabs not less than 1.0 MPa (10 kgf/);

c) solutions based on compressive strength - 4, 10, 25, 50, 75, 100, 150, 200;

d) stone materials for frost resistance - Mrz 10, Mrz 15, Mrz 25, Mrz 35, Mrz 50, Mrz 75, Mrz 100, Mrz 150, Mrz 200, Mrz 300.

For concrete, the frost resistance grades are the same, except for Mrz 10.

2.2. Solutions with a dry density of 1500 kg/ and more are heavy, up to 1500 kg/ are light.

2.3. Design grades for frost resistance of stone materials for the outer part of walls (12 cm thick) and for foundations (full thickness), erected in all construction and climatic zones, depending on the expected service life of structures, but not less than 100, 50 and 25 years , are given in table. 1 and paragraphs. 2.4 and 2.5.

Note. Design grades for frost resistance are established only for the materials from which the upper part of the foundations is erected (up to half the calculated depth of soil freezing, determined in accordance with the chapter of SNiP "Foundations of buildings and structures").

Table 1

|

Type of structures |

MRZ values for the expected service life of structures, years |

||

|

1. External walls or their cladding in buildings with indoor humidity conditions: |

|||

|

a) dry and normal |

|||

|

b) wet |

|||

|

c) wet |

|||

|

2. Foundations and underground parts of walls: |

|||

|

a) from plastic clay bricks |

|||

|

b) from natural stone |

|||

|

Notes: 1. Frost resistance grades for stones, blocks and panels made from all types of concrete should be adopted in accordance with the chapter of SNiP on the design of concrete and reinforced concrete structures. 2. Frost resistance grades given in table. 1, for all construction and climatic zones, except for those specified in paragraph 2.5 of these standards, can be reduced for masonry made of plastic pressed clay bricks by one level, but not lower than MP3 10 in the following cases: a) for external walls of rooms with dry and normal humidity conditions (item 1, a), protected on the outside by cladding with a thickness of at least 35 mm, meeting the frost resistance requirements given in table. 1, the frost resistance of facing bricks and ceramic stones must be at least MP3 25 for all service life of structures; b) for external walls with damp and wet conditions of rooms (items 1, b and 1, c), protected on the inside by waterproofing or vapor barrier coatings; c) for foundations and underground parts of walls of buildings with sidewalks or blind areas erected in low-moisture soils, if the level groundwater below the level of the ground by 3 m or more (item 2). 3. Frost resistance grades given in pos. 1 for claddings with a thickness of less than 35 mm, are increased by one step, but not higher than MRZ 50, and for cladding of buildings erected in the Northern construction-climatic zone - by two steps, but not higher than MRZ 100. 4. Grades for frost resistance of stone materials, given in pos. 2, used for foundations and underground parts of walls, should be increased by one step if the groundwater level is less than 1 m below the ground level. 5. Stone grades for frost resistance for masonry of open structures, as well as structures of structures erected in an area of variable groundwater levels (retaining walls, tanks, spillways, side stones, etc.), are accepted according to regulatory documents approved or agreed upon by the USSR State Construction Committee . 6. In agreement with the state construction authorities of the union republics, frost resistance testing requirements are not imposed on natural stone materials, which, based on past construction experience, have shown sufficient frost resistance under similar operating conditions. |

|||

2.4. For construction areas located east and south of the cities: Grozny, Volgograd, Saratov, Kuibyshev, Orsk, Karaganda, Semipalatinsk, Ust-Kamenogorsk, requirements for frost resistance of materials and products used for structures specified in table. 1, it is allowed to reduce by one step, but not lower than Мрз 10.

Note. The magnitudes of the steps correspond to the values given in paragraph 2.1, d.

2.5. For the Northern construction-climatic zone, as well as for the coasts of the Arctic and Pacific oceans with a width of 100 km, not included in the Northern construction-climatic zone, grades for frost resistance of materials for the outer part of the walls (for solid walls - to a thickness of 25 cm) and for foundations ( for the entire width and height) should be one step higher than those indicated in the table. 1, but not higher than MP3 50 for ceramic and silicate materials, as well as natural stones.

Note. Definitions of the boundaries of the Northern construction-climatic zone and its subzones are given in the chapter of SNiP on construction climatology and geophysics.

2.6. For the reinforcement of stone structures in accordance with the chapter of SNiP on the design of concrete and reinforced concrete structures, the following should be used:

for mesh reinforcement - reinforcement of classes A-I and BP-I;

for longitudinal and transverse reinforcement, anchors and ties - reinforcement of classes A-I, A-II and BP-I (taking into account the instructions of P.3.19).

For embedded parts and connecting plates, steel should be used in accordance with the chapter of SNiP on the design of steel structures.

3. DESIGN CHARACTERISTICS

Calculated resistances

3.1. The calculated compressive strengths of masonry made of all types of bricks and ceramic stones with slot-like vertical voids up to 12 mm wide with a masonry row height of 50 - 150 mm on heavy mortars are given in Table. 2.

table 2

|

Brand of brick or stone |

Calculated resistances MPa (kgf/), compression of masonry made of bricks of all types and ceramic stones with slot-like vertical voids up to 12 mm wide with a masonry row height of 50 - 150 mm on heavy mortars |

||||||||||

|

depending on the brand of solution |

at mortar strength |

||||||||||

|

Note. The calculated resistances of masonry on mortar grades from 4 to 50 should be reduced by applying reduction factors: 0.85 - for masonry on hard cement mortars (without additives of lime or clay), light and lime mortars up to 3 months old; 0.9 - for masonry on cement mortars (without lime or clay) with organic plasticizers. It is not necessary to reduce the calculated compressive resistance for masonry of the highest quality - the mortar joint is made under the frame with the mortar leveled and compacted with a lath. The project specifies the brand of mortar for ordinary masonry and for high-quality masonry. |

|||||||||||

3.2. The calculated compressive resistance of vibrobrick masonry with heavy mortars is given in table. 3.

Table 3

|

Brick brand |

Calculated resistances MPa (kgf/), compression of vibrobrick masonry on heavy solutions depending on the brand of solution |

||||

|

Notes: 1. The calculated compressive resistance of brickwork vibrating on vibrating tables is taken according to table. 3 with a coefficient of 1.05. 2. The calculated compressive resistance of vibrobrick masonry with a thickness of more than 30 cm should be taken according to table. 3 with a coefficient of 0.85. 3. Calculated resistances given in table. 3, refer to areas of masonry with a width of 40 cm or more. In self-supporting and non-load-bearing walls, sections with a width of 25 to 38 cm are allowed, while the calculated resistance of the masonry should be taken with a coefficient of 0.8. |

|||||

3.3. The calculated compressive strengths of masonry made from large concrete solid blocks from concrete of all types and from natural stone blocks (sawn or clean wood) with a masonry row height of 500 - 1000 mm are given in Table. 4.

Table 4(K)

|

Calculated resistances MPa (kgf/), compression of masonry from large solid blocks from concrete of all types and natural stone blocks (sawn or clean wood) with a masonry row height of 500 - 1000 mm |

|||||||||

|

depending on the brand of solution |

at zero strength |

||||||||

|

solution |

|||||||||

|

1000 800 600 500 400 300 250 200 150 100 |

|||||||||

|

Notes: 1. The calculated compressive resistance of masonry made from large blocks with a height of more than 1000 mm is taken according to table. 4 with a coefficient of 1.1. 2. Concrete classes should be taken according to Table 1 ST SEV 1406-78. The grade of natural stone blocks should be taken as the compressive strength MPa (kgf/), a reference cube sample tested in accordance with the requirements of GOST 10180 - 78 and GOST 8462 - 75. 3. The calculated compressive resistance of masonry made of large concrete blocks and natural stone blocks, the mortar joints in which are made under the frame with leveling and compaction with a lath (as indicated in the project), can be taken according to table. 4 with a coefficient of 1.2. |

|||||||||

3.4. The calculated compressive strengths of masonry made of solid concrete stones and natural stones (sawn or clean wood) are given in Table. 5.

Table 5

|

Brand of stone |

Calculated resistances MPa (kgf/), compression of solid concrete masonry, gypsum concrete and natural stones (sawn or clean wood) with a masonry row height of 200 - 300 mm |

|||||||||

|

depending on the brand of solution |

When the strength of the solution |

|||||||||

|

Notes: 1. The calculated resistance of masonry made of solid slag concrete stones made using slag from the combustion of brown and mixed coals should be taken according to table. 5 with a coefficient of 0.8. 2. Gypsum concrete stones may only be used for laying walls with a service life of 25 years (see clause 2.3); in this case, the calculated resistance of this masonry should be taken according to table. 5 with coefficients: 0.7 for laying external walls in areas with a dry climate, 0.5 - in other areas; 0.8 - for internal walls. Climatic zones are adopted in accordance with the chapter of SNiP on building heating engineering. 3. The calculated resistances of masonry made of concrete and natural stones of grade 150 and higher with smooth surfaces and dimensional tolerances not exceeding ± 2 mm, with a thickness of mortar joints not exceeding 5 mm, made with cement pastes or adhesives, can be taken according to the table. 5 with a coefficient of 1.3. |

||||||||||

3.5. The calculated compressive resistance of masonry made of hollow concrete stones at a row height of 200 - 300 mm is given in table. 6.

Table 6

|

Calculated resistances MPa (kgf/), compression of masonry made of hollow concrete stones with a masonry row height of 200 - 300 mm |

||||||||

|

depending on the brand of solution |

at mortar strength |

|||||||

|

Note. The calculated compressive resistance of masonry made of hollow slag concrete stones made using slag from the combustion of brown and mixed coals, as well as masonry made of gypsum concrete, hollow stones should be reduced in accordance with Notes 1 and 2 to Table. 5. |

||||||||

3.6. The calculated compressive resistance of masonry made of natural stones (sawn and clean wood) at a row height of up to 150 mm is given in Table. 7.

Depending on the brand of solution

at mortar strength

1. From natural stones with a row height of up to 150 mm

2. The same, with a row height of 200 - 300 mm

3.7. The calculated compressive strengths of rubble masonry made from torn rubble are given in Table. 8.

zero

Notes: 1. Given in table. 8 calculated resistances for rubble masonry are given at the age of 3 months. for grades of solution 4 or more. In this case, the brand of solution is determined at the age of 28 days. For laying at the age of 28 days. calculated resistances given in table. 8, for solutions of grade 4 or more should be taken with a coefficient of 0.8.

2. For masonry made of bedded rubble stone, the calculated resistances adopted in table. 8 should be multiplied by a factor of 1.5.

3. The design resistance of rubble masonry foundations covered with soil on all sides may be increased: when laying with subsequent backfilling of the excavation pits with soil - by 0.1 MPa (1 kgf; when laying in trenches "by surprise" with untouched soil and with superstructures - by 0.2 MPa (2 kgf/).

Preface

Goals and principles of standardization in Russian Federation established by the Federal

Law of December 27, 2002 No. 184-FZ “On Technical Regulation”, and the development rules -

Decree of the Government of the Russian Federation dated November 19, 2008 No. 858 “On the procedure

development and approval of sets of rules."

Rulebook Details

1 CONTRACTORS - Central Research Institute of Construction

designs named after V.A. Kucherenko (TsNIISK named after V.A. Kucherenko) - institute of OJSC "National Research Center

"Construction"

2 INTRODUCED by the Technical Committee for Standardization TC 465 “Construction”

3 PREPARED for approval by the Department of Architecture, Construction and

urban planning policy

4 APPROVED by order of the Ministry of Regional Development of the Russian Federation

(Ministry of Regional Development of Russia) dated December 29, 2011 No. 635/5 and put into effect on January 1, 2013.

5 REGISTERED by the Federal Agency for Technical Regulation and

metrology (Rosstandart). Revision of SP 15.13330.2010 “SNiP II-22-81* Stone and reinforced stone

designs"

Information about changes to this set of rules is published annually

published information index “National Standards”, and the text of changes and

amendments - in the monthly published information indexes “National Standards”.

In case of revision (replacement) or cancellation of this set of rules, the corresponding

the notice will be published in the monthly information index

"National Standards". Relevant information, notice and texts

are also posted in the public information system - on the official website

developer (Ministry of Regional Development of Russia) on the Internet.

1 area of use............................................... ........................................................ ...........1

2 Normative references................................................................... ........................................................ ...........1

3 Terms and definitions................................................... ........................................................ .......1

4 General provisions................................................... ........................................................ ..............1

5 Materials................................................... ........................................................ ........................2

6 Design characteristics................................................................... ........................................................ ..4

7 Calculation of structural elements according to the limit states of the first group (according to

load-bearing capacity) .................................................... ........................................................ .........18

8 Calculation of structural elements for limit states of the second group (according to

formation and opening of cracks and deformations)................................................... ...................35

9 Structural design................................................................... ...............................................37

10 Guidelines for the design of structures erected in winter...................................................62

Appendix A (mandatory) List of regulatory documents.................................................... .66

Appendix B (mandatory) Terms and definitions.................................................... ...................67

Appendix B (mandatory) Basic letter designations of quantities.................................................68

Appendix D (recommended) Calculation of walls of buildings with rigid structural

diagram........................................................ ........................................................ ...............................73

Appendix E (recommended) Requirements for reinforcement of facing masonry

layer........................................................ ........................................................ ................................76

Appendix E (recommended) Calculation of walls of multi-story buildings made of stone

masonry for vertical load on crack opening at

different loading or different hardness of adjacent areas

walls........................................................ ........................................................ ................................79

Bibliography................................................. ........................................................ ...................81

Introduction

This set of rules has been compiled taking into account the requirements of federal

laws of December 27, 2002 No. 184-FZ “On technical regulation”, dated

June 22, 2008 No. 123-FZ “Technical regulations on requirements

fire safety", dated December 30, 2009 No. 384-FZ "Technical

Regulations on the safety of buildings and structures."

The update was carried out by the team of authors of the TsNIISK named after.

V.A. Kucherenko - Institute of OJSC “Scientific Research Center “Construction”:

candidates of technical Sciences A.V. Granovsky, M.K. Ishchuk (leaders

works), V.M. Bobryashov, N.N. Kruchinin, M.O. Pavlova, S.I. Chigrin;

engineers: A.M. Gorbunov, V.A. Zakharov, S.A. Minakov, A.A. Frolov

(TsNIISK named after V.A. Kucherenko); candidates of technical Sciences A.I. Bedov (MGSU),

A.L. Altukhov (MOSGRAZHDANPROEKT). General edition - Ph.D. tech. Sciences O.I. Ponomarev (TsNIISK named after V.A. Kucherenko).

SET OF RULES

STONE AND REINFORCED STONE STRUCTURES

Masonry and reinforced masonry structures

Date of introduction 2013-01-01

1 area of use

This set of rules applies to the design of stone and

reinforced masonry structures of new and reconstructed buildings and structures

for various purposes, operated in climatic conditions Russia.

The standards establish requirements for the design of stone and reinforced stone

structures built using ceramic and silicate bricks,

ceramic, silicate, concrete blocks and natural stones.

The requirements of these standards do not apply to the design of buildings and

structures subject to dynamic loads, erected on

undermined territories, permafrost soils, in seismically hazardous areas, and

also bridges, pipes and tunnels, hydraulic structures, thermal units.

2 Normative references

Regulatory documents to which there are references in the text of these standards are

are given in Appendix A.

Note - When using this set of rules, it is advisable to check

the effect of reference standards and classifiers in a public information system on

official website of the national body of the Russian Federation for standardization on the Internet

or according to the annually published information index “National Standards”, which

published as of January 1 of the current year, and according to the corresponding monthly published

information signs published this year. If the reference document is replaced

(changed), then when using this set of rules you should be guided by the replaced

(modified) document. If the reference document is canceled without replacement, then the position in which

a reference to it is given, applies in the part not affecting this reference.

3 Terms and definitions

This set of rules adopts the terms and definitions given in Appendix B.

4 General provisions

4.1 When designing masonry and reinforced masonry structures, you should

apply design solutions, products and materials that ensure

required load-bearing capacity, durability, fire safety,

thermal characteristics of structures and temperature and humidity conditions

(GOST 4.206, GOST 4.210, GOST 4.219).

4.2 When designing buildings and structures, it is necessary to provide

measures to ensure the possibility of erecting them in winter conditions.

4.3 Application of sand-lime bricks, stones and blocks; stones and blocks from

cellular concrete; hollow ceramic bricks and stones, concrete blocks with

voids; ceramic bricks of semi-dry pressing are allowed for external

walls of rooms with wet conditions, provided that they are applied to their internal

surface of the vapor barrier coating. The use of these materials for

walls of rooms with wet conditions, as well as for external walls of basements, plinths and

foundations are not allowed.

The use of three-layer masonry with effective insulation for external walls

rooms with wet operating conditions are allowed provided they are applied to

their internal surfaces have a vapor barrier coating. The use of such masonry

for external walls of rooms with wet operating conditions, as well as for

external walls of basements are not allowed.

4.4 The design of building elements should not be

the cause of the hidden spread of fire throughout a building, structure, or structure.

When using combustible insulation as an inner layer, the limit

fire resistance and structural fire hazard class of building structures

must be determined under standard fire test conditions or by calculation and analytical method.

Methods for conducting fire tests and calculation and analytical methods

determination of fire resistance limits and structural fire hazard class

building structures are established by fire safety regulations

security.

4.5 Application of this document ensures compliance with the requirements

Technical Regulations “On the Safety of Buildings and Structures”.

.

(54)

.

(54)