Country house or country cottage will not be able to cope without a reliable sewer system. Progressive hydraulic devices, which include a fecal pump with a grinder, help ensure its uninterrupted functioning. It has several versions suitable for specific operating conditions. What it is and how to choose the right unit is in our article.

Methods of use

The device has multi-purpose use in domestic and industrial conditions. It is installed for seasonal pumping in warm time years in the following cases:

- emptying the cesspool;

- pumping out of septic tanks;

- cleaning containers with stagnant contaminated water.

The built-in mechanism is capable of grinding not only fibrous structures that fall into the sewer, but also perform other work for the garden. Knives can easily chop up organic elements found in water:

- grass or fallen leaves from trees;

- seaweed;

- particles of household waste, etc.

The resulting fine-grained mixture does not load the pump motor and increases the throughput of the connected pipes.

Due to the fact that a fecal pump with a grinder for cesspools literally cuts the garbage it encounters into millimeter-sized fragments, the risk of jamming is reduced. This feature allows the devices to be used in transporting the following liquids:

- rain or storm drains (containing leaves or small branches);

- drainage from the sink (there are food remains);

- retraction dishwasher(large particles come across);

- toilet sewage - waste products, toilet paper, foreign objects, etc.

A variety of sewage pumps with a grinder are necessary for places where the sewer system is used uncontrollably by a large number of users, in particular, we are talking about public toilets.

Foreign solids can also get into pipes in catering establishments, campsites or factories. Water is pumped out with units of this type from natural reservoirs for their partial drainage or for liquid selection. Silt or algae can enter inside. Additional cutting is not necessary in systems with channels with an internal diameter of less than 80 mm.

Construction and basic elements

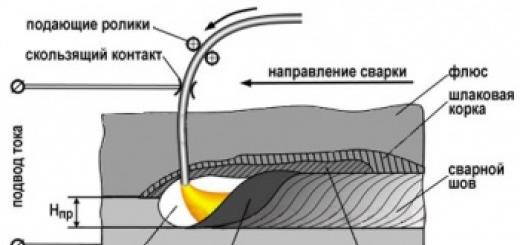

To obtain a fine fraction from organic and inorganic residues, a cutting unit is installed in the design. It has several options:

- the blades of the auger impeller, which has a conical shape, are sharpened on the outer side;

- sharpened blades pass closely along the polished end of the output cylinder, providing a scissor effect;

- a pair of knives is located coaxially with the diameter, processing incoming waste;

- the cutting module is mounted next to the hole and rotates through an additional gearbox.

The rest of the design resembles a regular one drainage pump. The design also includes:

- Electric motor. Household products operate on 220 V, industrial products are designed for 380 V.

- Frame. Different copies are made of different materials.

- Fence part. Allows fluid to flow without blocking the inlet.

- Outlet pipe. It allows connection to a pipeline for further transportation of liquid.

An important feature of the fecal pump with a grinder for cesspools is the use of materials resistant to external influences for the housing and working units. They must withstand mechanical and hydraulic loads, and also not be damaged by chemicals. A durable body must not be destroyed by fine sand acting as an abrasive.

The material for the body is:

- Stainless steel - this material is practically not subject to corrosion.

- Cast iron - powerful body withstands significant mechanical load.

- Plastic - used in budget models, resistant to chemicals.

Knives are made only from stainless high-alloy steel. They have an additional protective coating.

Equipment functionality

It is clear that the main function of the fecal apparatus is to pump out contaminated liquid from the sewer, and it is for this purpose that it is most often purchased. But he also copes with other tasks 100%. We are talking about the following potential:

- When the house is located in a low-lying area, any heavy rainfall leads to flooding of the basement and basement floors. Self-priming equipment is capable of pumping out water with solid inclusions, including small stones.

If flooding occurs regularly, you can make pits or storm drains in the basement or basement to place the unit. And if you choose equipment with a float, you don’t even have to pull it out - it will start working as the pit fills.

- It is convenient to use a pumping unit for cleaning drainage holes or collectors. It is also convenient to use it for pumping out the chambers of a septic tank in order to transfer liquid to the filtration field.

- If there is a river or lake nearby, you can use fecal equipment with a grinder to collect water for irrigation or other technical needs. Strong steel knives are capable of cutting through any solid inclusions, not counting mud, algae and branches, so there will be an abundance of water cleared of foreign objects in the area.

VIDEO: Submersible fecal pump with grinder

Types of models

Each fecal pump with grinder for cesspools belongs to one of three large groups. The main difference between them is the installation method:

- Submersible pump. It is located at a shallow depth in the liquid. The main advantage is the processing of waste up to 45 mm in diameter, and it also has significant lifting power. The disadvantage is inconvenient maintenance and repair.

Immersion models are the most popular in households

- Surface fecal pumps with grinder. They are based on land, and the intake liquid is supplied through a special pipe or hose with a diameter of more than 60 mm. The convenience lies in the fact that you can pump out liquid from a container with a small diameter. It is enough to lower the intake sleeve there. You can permanently place the device near the toilet, kitchen or bathroom.

Surface equipment is quite bulky and very noisy compared to submersible products - they are installed outside the house

- Semi-submersible vehicles. Rare examples have a shredder, since the maximum diameter of possible contaminant particles is limited to 15 mm.

In addition to devices for household needs industrial installations are used. They are installed in institutions, enterprises and organizations.

When choosing a product for pumping liquid from the kitchen or from a dishwasher, it is necessary to select a product capable of transporting hot liquid with a temperature of up to 80-90°C.

Type of operation

Installation depends on the method of use. In some households, pumping is used regularly, sometimes from time to time.

In the case of stationary operation, it would be appropriate to use a submersible fecal pump with a grinder or use a semi-submersible type unit. They will need dismantling only for the period of preventive maintenance or repair. They will be most comfortable in a prepared receiving well. The diameter of the hole must be at least half a meter. All outlets from the bathtub, kitchen, bathhouse and other places are connected to such a tank.

It will be necessary to configure the system for pumping depending on the degree of filling of the well. After removing waste, it is supposed to turn off the automation so that air is not trapped.

If pumping involves long breaks in time, then it is worth using a submersible pump with a small device in the form of rigid guides. Additionally, a pulling cable is attached to the device.

Vertical posts provide the desired working position. Moving along them, the device descends to the very bottom of the pit. After work, take out the unit, clean and dry it. It is preferable to store it in a dry, warm place, such as a utility room, garage or pantry.

Main evaluation criteria

If you need a fecal pump with a grinder for cesspools or pits, you should focus on certain parameters. Among them:

Power and voltage

Most modern household equipment runs on a standard 220V power supply. Power determines its functional characteristics - column height, pumping speed, grinding fraction, etc. This information is reflected in the technical data sheet of the product and must be studied.

Example. If you need a fecal pump with a grinder for sewage of a small country house, which can also be used for pumping water from the basement or draining, then equipment with a power of 500 W will do just fine. And if you need equipment that will work constantly and “serve” a family of several people, the optimal power will be 1-1.5 kW.

Performance

This is the volume of liquid pumped per unit of time. For all types of suction equipment, this indicator is measured in liters per minute. An ordinary household unit with a power of 500 W pumps about 150 liters of liquid per minute, and 1.5 kW equipment will pump 650-700 liters. This means that even with a large volume it will not take much time to work.

Column height

It is usually measured in meters. For pumping devices, this indicator indicates the height to which the water column rises at the time of pumping. And if for ordinary submersibles this is a unit of vertical design, then for fecal ones it is a horizontal unit. Considering that it is often necessary to work with heavily contaminated liquids, the average indicator is taken as a basis - 1 created pressure ensures the movement of water over a distance of 3.5-4 meters.

For domestic needs, 10-15 meters of water column is sufficient.

What is the body made of?

Metal is an absolute priority, since it is many times stronger than even the highest quality plastic, although modern polymers have repeatedly confirmed their strength. More expensive specimens are made of stainless steel, simpler ones are made of cast iron. We are not even talking about ordinary steel, since feces and wastewater are too aggressive chemical composition so that the steel body can cope with this for a long time.

.png)

Cast iron fecal appliances with a grinder are very massive and heavy, so carefully choose the thickness of the rope. In addition, cast iron is a brittle material and can burst if it receives an accentuated blow.

The presence of a float (water level sensor)

Even if the unit is not intended to be used in automatic mode, the presence of a water level sensor with a shutdown function will protect it from emergency operation outside a liquid medium.

Immersion depth

It is clear that lowering a suction unit of a certain power and performance to a depth greater than technically designed and expecting that it will work normally is at least strange. Each sample has its own parameter for the distance to the water surface, and this is reflected in the data sheet.

Solids size

Since this is a fecal pump with a grinder, there is a certain diameter of foreign matter that it is able to grind. For domestic needs, it is enough to choose 20-30 mm, this is an excellent indicator.

Please note that it is the size of the solids that matters, not their hardness or density. The knives are capable of crushing even stones.

Working environment temperature

Depending on the environment in which - hot or cold - the drainage device is planned to be used, the operating temperature is also selected. Cold indicator - up to 35°C. Hot - up to 90°C.

Rating of the best models of fecal pumps with a grinder

Let's look at several popular, in-demand devices that have proven themselves in the domestic hydraulic pump market:

Gilex 150/6

Russian manufacturers offer a budget model for 3,000 rubles. It is of the household type and can be used for pumping out sewerage in the house. The power is 0.4 kW with a maximum pressure of 6 m. It operates from a household power supply of 220 V and is capable of flowing up to 9 m 3 / hour. Stainless steel body.

Grundfos SEG

German assembly and high quality are noticeable in professional equipment for 50,000 rubles. The cast iron body is equipped with an overheating protection system and is protected from corrosive processes. The power is 900 W, and the throughput reaches 15 m 3 / hour. Starts from a voltage of 220 V. Operates at a depth of up to 10 m.

ESPA Draincor 180

Spanish installation, providing excellent value for money among analogues. It withstands various environments and operates with minimal noise levels. The body of the device is cast iron. Power is 1.7 kW. The pressure reaches 12.5 m. Capable of withstanding voltage drops of 220±10% V.

For a permanent connection in the toilet, the Grundfos Sololift2 line is used. It starts and stops automatically after liquid enters the working cavity. The unit is installed directly behind the toilet.

VIDEO: Grundfos SEG sewage pump with cutting mechanism

Reading time: 9 minutes.

Life on summer cottage or just in your own home - this is an opportunity to take a break from the bustle of the city. However, in addition to pleasant moments, problems of drainage and sewerage arise.

A septic tank is needed to drain water from the house and, of course, fecal water. After all, it’s not very pleasant to catch the smell emitted by a cesspool located on your property.

To pump out fecal water, it is necessary to use an appropriate electric pump.

Types of fecal electric pumps

To choose the right fecal pump, you should know that fecal pumps are:

- submersible;

- semi-submersible;

- superficial.

Submersible

Submersible fecal pumps are somewhat different from conventional ones. They are capable of pumping out small debris and solid particles up to 500 mm in size along with water, depending on the model.

Quite often, private houses cannot be connected to a centralized sewer system, or it runs far, is completely absent, or the slope of the pipe does not allow this. A smart owner knows that water drainage through pipes from the house should take place with a slight slope. In such cases, a septic tank or cesspool comes to the rescue in conjunction with which, to ensure your comfort, a fecal pump is created.

Considering that this type of pump will operate in an aggressive environment, the appropriate material for its production is selected: the body is made of cast iron or stainless steel. A submersible fecal pump with a grinder, installed at production facilities, has become an integral part of them.

Since the fecal submersible pump will be located below the liquid level, such specimens are equipped with special float systems that turn off the pump when the set liquid level drops. It descends into a pit or septic tank on a cable, and a hose is attached to the pump through a fitting, which is led to the required location.

Semi-submersible

A semi-submersible fecal pump is located on the surface of the liquid using a special float. The engine is above the water, and the pumping element itself is submerged in the water. The maximum diameter of solid particles passed through in such samples is not large, so a special grinder is used in conjunction with it.

However, for domestic use, even without it, it can easily pump out decomposed masses in a septic tank, with debris and particles up to 15 mm.

Superficial

Fecal surface pumps have slightly worse characteristics than the previous two types. Their power is lower, as is their performance. The throughput of solid parts does not exceed 5 mm.

The advantage is high mobility and ease of use, as well as their price is much lower. An external pump for fecal matter is well suited when pumping is required more than once a quarter. Basically, they pump no more than 1500 liters per hour.

The electric pump itself is installed on the surface (near a cesspool or septic tank), only a hose is lowered into the water. It is not used for constant use, as it can fail if exposed to precipitation. It is recommended to bring it indoors after pumping out the liquid.

There are cases when such an electric pump is installed under a canopy, but the moisture in it will freeze in winter and the pump will fail. It is much better if it is installed in a heated room next to a well.

Electric pump with chopper

When installing a fecal pump, it is best to think about all the points that will affect its operation. Some models pump out 1100L per hour, while others pump out 1500L per hour.

Production samples with large dimensions are capable of pumping out much more liquid in a short period of time, but their water intake depth generally does not exceed 6 m. With a power of 250 W, which is not very much, they are capable of squeezing water out to a distance of up to 50 m. The peculiarity of this type of fecal pump is that it can be used on large objects or purchased one for several houses or cottages.

When living in a private house, cottage or other residential property that is not connected to a centralized sewer system, you should understand that you cannot do without water drainage and a cesspool or septic tank. As well as without a fecal electric pump, selected in accordance with the conditions in which it will be operated. A wise choice and proper prevention will help you forget about the problem of pumping out your cesspool and septic tank for many years.

Cleaning waste containers from contaminated water is a serious issue. The use of conventional pumps for pumping water is impossible here due to the increased viscosity of the liquid and the presence of solid and fibrous substances in it. For such types of work, fecal pumps with grinders, or as they are also called fecal pumps, were specially designed.

Centrifugal pumps are used as the basis for the production of fecal tanks with grinders. The shredder mechanism uses an additional impeller with cutting edges. The grinder device can grind solid particles with a fraction of no more than 8 centimeters.

Classification

Depending on the design, pumps can pump both cold liquids, no more than 40 degrees, and hot liquids, up to 90 degrees Celsius.

Depending on the installation location, fecal pumps can be divided into 3 groups:

- Surface installation.

- Semi-submersible installation.

- Submersible installation.

Surface method

Surface devices are the most powerful. They can create the highest pressure and flow rate of the pumped substance. Overall size is not as important for them as for other types of similar units. Such units can be driven by either an electric motor or an internal combustion engine.

For surface pumps there is no need to make the pump and motor housings from alloy steel. Only the supply hose, through which the liquid and the impeller are supplied, comes into contact with the pumped wastewater. There are types of units capable of connecting directly to a source of fecal water. For example, to the toilet.

When choosing a model, you need to pay attention to the following parameters:

- Motor power

- Maximum suction depth.

- Created outlet pressure

- Diameter of inlet and outlet pipes.

Depending on the engine power, installation requirements change. For low-power household pumps, just a flat surface is suitable. Further, progressively. The greater the power, the more serious the foundation will need to be prepared. The most powerful feces are placed on a buried concrete foundation and attached to it through vibrating inserts.

The positive aspects of using surface installation include the following:

- Unit mobility. Possibility of use on several objects. Where occasional use is required.

- Easy to install and operate. There is no need to create a special seat for operation.

- Low price. Due to the absence of contact of the housing with an aggressive environment, there is no need to manufacture the outer housing from alloy steel or cast iron.

In addition to positive qualities, surface pumps also have negative aspects:

Quite a lot of noise is created from the switched on unit.Semi-submersible method

The installation principle of a semi-submersible pump is based on partial immersion in the pumped liquid. With this installation, the pump itself is immersed in the liquid, and the electric motor remains on the surface. Basically, this type of equipment is used for pumping liquids from shallow depths.

To use when the depth of the tank is sufficiently large, it is necessary to mount a floating platform like a raft. Then, when pumping out liquid, the platform itself will lower following the liquid level. The cost of such pumps is higher than that of surface pumps.

During manufacturing, it is necessary to use alloy steel not only for the pump impeller and grinder disk, but also for the pump body.

When choosing a semi-submersible type of equipment, you need to pay attention to the following points:

- Electric motor power.

- Created outlet pressure.

- Volume of pumped liquid per hour.

The positive aspects of using this type of equipment include the following:

- Opportunity mobile operation.

- Opportunity operation in small volumes of liquid, where it is impossible to operate surface or submersible pumps.

Negative qualities include the following:

- Seasonality of operation.

- If necessary pumping liquids with a large reservoir depth requires additional equipment.

Immersion method

This type of equipment belongs to the most difficult segment of pumps to produce. When producing this type, it is necessary to use special steels for all parts included in the equipment.

In addition to protection from aggressive environments, it is necessary to ensure the tightness of all connections to prevent liquid from entering electrical part pump The insulation of the supply electrical cable must also withstand exposure to aggressive environments.

Taking into account all the production requirements, this type of equipment is the most expensive. This type is used only permanently.

To install a submersible sewer with a grinder, you must perform the following steps:

- Securely fasten load-bearing beam above the tank. The beam must be selected taking into account the weight of the pumping unit and the outlet pipe. The beam must pass through the center of the tank.

- On a surface connect the outlet pipe to the outlet pipe.

- Connect the pump with a beam using a steel cable or chain. The length of the cable or chain must be equal to the installation depth of the unit.

- If necessary provide a lifting mechanism to remove the unit from the tank for repairs or replacement.

- Supply the feeder electrical cable from the distribution board to the installation site.

The positive aspects of using a submersible unit include the following factors:

- Opportunity operation all year round.

- Absolutely no noise produced during work.

The negative aspects include the following:

- Difficult to install.

- The need to remove the unit from the tank for repairs.

- High price.

How to choose the right equipment?

To select the right equipment for a particular facility, you need to consider several important points:

To select the right equipment for a particular facility, you need to consider several important points:

- Frequency of use.

- Tank location.

- Volume pumped liquid.

- Liquid lifting height or, in the case of surface or semi-submersible units, suction lift.

Let's look at an example:

If it is necessary to periodically pump process water in small quantities, then it makes sense to use a mobile surface option. Also, it is perfect for use in enclosed spaces. This type of equipment can be mounted directly to a storage tank located in the basement of the building.

In case of periodic operation at different points, a semi-submersible type of equipment is better suited. This type of unit can be multifunctional. It is suitable for collecting water from a shallow reservoir and for periodically cleaning household sewer pits.

For stationary use in large-volume sewer pits, it is better to use submersible fecal dumpers with a grinder. Especially if they are located far from housing. With proper organization of use, these units can be used in fully automatic mode.

The best models and their costs

Manufacturer Rona (Slovenia) model WQD 1500

Characteristics:

- engine power: 1.5 kW;

- productivity 1.2 m3/h;

- head: 20m;

- Max. immersion depth: 9m;

Price – approximately 6600 rubles.

Manufacturer Aquatica (Ukraine) model 773414

Characteristics:

- power: 1.5 kW;

- productivity: 24m3/h;

- head: 23m;

- Max. immersion depth: 5m;

Approximate price 11880 rub.

Manufacturer Optima (Poland) model V1500-QG

Characteristics:

- electric motor power 1.5 kW;

- maximum head 0 (m);

- throughput 18.0 (cubic m/hour);

- Max. immersion depth: 5m;

Estimated cost 11880 rub.

Manufacturer Dnepr-M (Ukraine) model NDC 2 PN

Characteristics:

- rated power – 2.6 kW;

- productivity – 25 m3/h;

- lifting height – 16 m;

- immersion depth – 5 m;

Estimated cost 6600 rub.

Manufacturer HERZ (China) model WRS32/11–180

Characteristics:

- electric motor power 1.1 kW;

- maximum head 18.0 (m);

- throughput 16.8 (cubic m/hour);

- Max. immersion depth: 8m;

Estimated cost 16,500 rubles.

- Before purchasing equipment carefully study the place of future operation.

- Choosing technical specifications it is necessary to add 10–20% of power for possible unaccounted loads or future development.

- Before use check the functionality of the protective automation.

- Do not forget periodically carry out preventive flushing of equipment. This will help extend the service life.

Areas of application for domestic and industrial sewage pumps with grinders. Fecal pumps with choppers: the principle of operation of the devices and the main types of household units

Owners country houses The problem of draining contaminated wastewater cannot always be solved by connecting to central communications. Good decision The problem in this case is a fecal pump with a grinder, using which it is convenient to pump out wastewater.

Sewage pump with grinder for sewage in a private house

Sewage pump with grinder for sewage in a private house A fecal pump with a grinder is indispensable in cases where, for any reason, it is problematic to equip a septic tank, and the owners of country houses have to make do with a cesspool. Special pumping units help solve the problem of cleaning cesspools.

After all, these devices are not afraid of pebbles, grains of sand and any kind of solid debris, easily pumping out any water: with the remains of silt and dirt, clogged with household waste.

The pump with grinder makes it easy to maintain the sewer system and perform pumping dirty water

The pump with grinder makes it easy to maintain the sewer system and perform pumping dirty water With their help it is much easier:

- maintain toilets and storm drains;

- empty the outdoor pool for the winter;

- clean containers and pits from sediment;

- eliminate spring floods in basements and basements.

It is mandatory to install a fecal pump with a grinder in houses where the internal sewerage distribution is made with pipes having a small diameter. Keeping track of which family members inadvertently or deliberately throws small objects into the toilet is quite problematic.

A household fecal pump with a grinder installed behind the toilet will easily grind all the solid particles that get into it, forcing the wastewater to be discharged into a centralized riser.

Installing a sewage pump behind the toilet in the house

Installing a sewage pump behind the toilet in the house The installation of industrial sewage pumps also helps to solve the issue of ensuring uninterrupted operation of sewage systems in public places, where the daily flow of visitors often leads to a serious load on the system.

Unfortunately, not all people have an understanding of the culture of behavior and an understanding of the rules for using showers and toilets, throwing objects into the toilet that can clog the pipes. Thanks to the ability of industrial sewage pumps to pump water with inclusions the size of which reaches 35 mm or more, solving this problem will not be difficult.

How the device works

A fecal pump with a grinder is a unit in the form of a small container, inside of which a cutting device is installed and the pump itself is mounted. When wastewater enters the container, the automation system starts the grinding mechanism. The particles, crushed by a knife to a gel-like state, are discharged into the pipeline under the action of a pump along with water.

Diagram: operating principle of a fecal pump

Diagram: operating principle of a fecal pump The blade block of the fecal pump can be one of several ways:

- The impeller has a conical screw shape with sharpening along the outer part of the blades. It creates centrifugal pressure of the liquid in the working chamber.

- The impeller blades fit against the bottom wall of the cylinder, creating a scissor effect.

- When the knives are installed in a separate block before entering the working chamber, but their axis coincides with the impeller itself.

Unlike drainage analogues, fecal pumps are equipped with special devices for grinding various types of inclusions and a mesh filter that retains solid elements. Therefore, such devices are ideal for cleaning cesspools filled with wastewater containing solid particles.

Household and industrial models: what is the difference?

Installations for domestic and industrial use are available on sale. Both are designed for constant contact with alkalis, acids and various types of aggressive liquids.

Industrial sewage pumps

Industrial sewage pumps Important: In household fecal pumps, the components and parts are made of impact-resistant plastic that is resistant to chemical influences. In industrial pumps, the housing and working chambers are made of stainless steel and solid cast iron. Thanks to this, they are characterized by higher performance parameters and a long service life.

But still, the main difference between household and industrial pumps is the performance of the units, which largely depends on their power. Therefore, when choosing a device, you should focus on the number of people living in the house, as well as the maximum depth of the cesspool and the distance to the point where the sewage will be drained.

This approach will prevent unnecessary costs, since the difference in cost between industrial pumps with grinders and their household counterparts is quite large.

Types of pumping units

Grinder pumps are available in submersible, semi-submersible and surface type. They can be permanently installed, or temporarily installed for one-time work.

Submersible option

The unit is a monoblock designed for complete immersion in a liquid medium and installation at the bottom of a storage tank. Submersible sewage pumps with a grinder are used for periodic pumping of wastewater, for example: cleaning a toilet and cesspool.

Submersible sewage pump

Submersible sewage pump They are characterized by high productivity, due to which they are widely used not only in private households, but also in industry. They are unrivaled in terms of waterproofing and resistance to adverse environments.

Important: Household units with a power of 40 kW can easily lift up to 400 liters of liquid per hour to a 20-meter height.

Their installation involves the arrangement of a “seat” equipped with metal guides, allowing the pump to be positioned in the desired direction. A rope or strong cable is provided to lower the unit. The pump is simply immersed along the guides, “seated” on the pipe.

The only drawback of such devices is the limitation of temperature conditions. Since the submersible pump motor is cooled by the pumped liquid itself, its temperature should not exceed 40°C. To prevent engine overheating from dry running, many models are equipped with a system automatic shutdown, actuated by a float switch.

Semi-submersible models

Such devices are mounted on the surface using a special float. Only the pump part is immersed in the drains, and the engine remains outside the cesspool. The immersion depth of the unit is limited by the length of the hose.

Operation of a submersible sewage pump

Operation of a submersible sewage pump Important point: The diameter of the channels in household semi-submersible pumps is somewhat smaller and, for this reason, they are rarely equipped with a cutting mechanism. This factor significantly limits the scope of their application.

Basically, such units are used for removing oily and liquid waste, as well as cleaning toilets from fecal matter with solid inclusions, the diameter of which does not exceed 20-50 mm.

Unlike submersible models, semi-submersible pumps are made from materials that do not effectively resist corrosion. But, if you focus on the operating principle of such devices, you don’t need to focus on this parameter.

Surface aggregates

For surface models equipped with a grinder, the cutting mechanism is located near the outer edge of the sump pit, and only the suction hose is immersed in the liquid. External household pumps are easy to install. Among the main advantages of such units it is worth highlighting:

Surface pump for sewerage in a private house

Surface pump for sewerage in a private house - Low cost compared to other types of fecal pumps;

- Possibility of use for cleaning cesspools and toilets located at a distance from each other;

- Ability to pump liquid whose temperature reaches 100°C. The maximum size of solid inclusions is 75 mm.

- The engine of the unit is cooled by air and contact of the pump with the pumped liquid is eliminated, which helps to extend the service life of the unit.

- But still, surface devices are the least widespread, since their use is associated with the risk of clogging the receiving sleeve with waste even before it reaches the shredder knives.

In terms of technical characteristics, they are significantly inferior to semi-submersible and, even more so, submersible analogues. The suction height of external pumps does not exceed 8.5 meters.

Such units are not intended for stationary use, since their housings do not have waterproofing.

For the same reason, they cannot be used at sub-zero temperatures. For the operation of surface pumps, it is advisable to equip an additional shed.

Sewerage installation with a pump: video

Creating comfortable living conditions in a private home is by no means limited to equipping heating, ventilation and air conditioning systems, ensuring an uninterrupted supply of water and electricity, performing high-quality finishing and saturating the premises with comfortable furniture and modern household appliances. You definitely have to think about the “dirty” side of the issue, invisible in Everyday life, but this does not lose its extreme importance. We are talking about the problem of collecting and recycling various waste that inevitably accumulates in the process of family life.

One solution is to order a sewage disposal truck to pump out accumulated sewage as the cesspool fills. But in some cases it is quite possible to do it on your own by finding the possibility of waste disposal. But in this case, special equipment will be required, in particular, a fecal pump with a grinder for cesspools. How to choose such a device and what functions it can perform is described in this publication.

General structure of a fecal pump with a grinder

First, let's define the types of fecal pumps, which depend on the location of their installation.

- Surface fecal pumps are self-priming devices capable of lifting a viscous liquid with a significant amount of contaminants from a certain depth through a hose lowered into the waste pit. The sewage disposal machines familiar to most private home owners are equipped with just such a surface self-priming pump.

There are practically no advantages to such a scheme in terms of domestic use. Such pumps are usually very large and heavy, otherwise they will not be able to cope with the suction of viscous liquid from depth. Such bulkiness entails the need for a permanent installation, which, in turn, will require the creation of certain conditions - protection from precipitation and negative air temperatures. Most often, surface pumps are used in wastewater treatment plants, factories or agricultural complexes. Purchasing such a device for a private home is an extra hassle, although it will certainly cope with the task of cleaning an ordinary cesspool.

In addition, the operation of the electric drive is always accompanied by noise, which is also amplified by the cooling of the pump - an air circuit is used here, that is, a fan placed on the motor axis, covered with a casing.

- Semi-submersible sewage pumps are almost always permanently installed equipment that requires special installation. The idea is that the electric drive (motor) is located on top, in the air, and the working chamber of the pump is immersed in the waste storage tank. They are connected by a long shaft to transmit torque.

Such pumps have proven themselves well at large facilities, for example, at livestock farms, where regular, almost daily pumping of accumulated waste is required. They also find application in a branched sewage system connected to one volumetric storage tank, which also has to be emptied quite often.

But in a household setting, the use of such equipment, which is bulky, difficult to install and requires space, is completely unreasonable.

- The best choice for household use- This is a submersible sewage pump. They are small in size, easy to use periodically or continuously, unpretentious, and operate without noise. They do not require air cooling, since during operation they are in a liquid medium that removes heat well from the electric drive.

Despite the very wide variety of models on sale and the significant range in prices, almost all submersible fecal pumps are configured approximately the same.

All such pumps are a vertically located cylinder. Top part– electric drive unit, protected by a housing (item 1), metal, less often – plastic. The power cable (item 2) enters the housing from above, ensuring complete sealing of the entry point. To carry the pump and hang it in a cesspool on a cable, a metal handle (item 3) is rigidly fixed to the body. Special eyes may also be provided to secure the suspension.

Inside the housing there is an electric drive - a stator (pos. 4) and a rotor (pos. 5) which is mounted on a vertical shaft (pos. 6) to transmit rotation to the pump part. The shaft rests on groups of bearings (item 7).

Between the electric drive and the working chamber of the pump there is an oil chamber (item 8) - a sealed cavity filled with special technical oil. It performs three functions at once - it ensures a tight fit of the sealing collars to the rotating shaft, ensures constant lubrication of the bearings and serves to remove heat, that is, cool the friction units.

Below is the pump itself - the pumping part. This is a body (item 9) of a certain configuration - a “snail”, in which the working chamber is located. The bottom of the chamber is usually closed with a lid (pos. 10), providing access to the pumped liquid in the center. Often the special shape of this lid also plays a certain role in grinding waste.

Inside the chamber there is an impeller (item 11) with an impeller. The rotation of the wheel creates a powerful centrifugal acceleration of the liquid, a significant increase in pressure at the periphery of the chamber with a vacuum in the center, which leads to the formation of a flow with high pressure, which is discharged through a special pipe (item 12). The pipe can be stationary, directed upward or perpendicular to the axis of the pump, or it can have a flange connection, and then the direction of the output flow can be changed if desired - upward or to the side. The coupler may have a groove for attaching a hose with a clamp, or a locking part - for special hoses, like firefighters, which, by the way, can also be included in the pump kit - as shown in the illustration.

Fecal pump

At the bottom of the pump is attached either a support platform with holes for the passage of liquid to the working chamber (item 13), or special legs for reliable installation of the pump on a solid base.

As already mentioned, quality fecal submersible pumps are exposed by a cutting mechanism. Wastewater does not contain large concentrations of fibrous waste, paper, fabric, plastic bags, kitchen cleaning and so on. In order not to impede the operation of the pump impeller and to prevent the creation of plugs in the hose when pumping liquid, the cutting mechanism will crush these inclusions to sizes that will no longer pose serious interference.

Cutting mechanisms may vary slightly.

- One of the varieties is where a sharpened impeller with knife blades is placed on the shaft in front of the chamber entrance.

- Another type is an impeller blade, the blades of which are tightly ground to the outer plane of the lower cover of the pump’s working chamber.

Essentially, exactly the same principle as in a regular home meat grinder

- The next variety - the knife has a cylindrical shape and is equipped with two cutting edges, and two protrusions are made at the entrance hole into the chamber. When rotating, the cylinder edges and protrusions work like scissors.

- The knife can stand motionless, and the working pair to it, to create the effect of scissors, is created by the edges of the impeller blades.

- Finally, the impeller itself can have a very intricate shape with blades turning into sharply sharpened knives.

It is difficult to say which type is better. When choosing a pump, it would probably be useful to clarify whether it is possible to purchase spare parts for repairing the chopper, and how much they will cost.

Many pumps are immediately equipped with a water level switch with a built-in switch. This allows them to be included in automated system pumping out storage tanks. The control unit will turn off the pump when the container is drained to a specified level, and turn it on when the water rises again to a certain level. The presence of a float switch does not in any way prevent the pump from being used in normal, “manual” mode, however, the cost of such devices will be slightly higher.

Undoubtedly, various models Leading pump manufacturers may have their own design features, but the design principle outlined above will still remain the same.

What is the functionality of a fecal submersible pump?

The direct purpose of the fecal pump is clear, but it is not limited to this. Its unpretentiousness and high performance open up many other possibilities for use in the most different cases that owners of their own homes have to face.

- If the site is located in a lowland or on marshy soils, then the accumulation of moisture in the basement or basement is often a common occurrence. If you equip them with pits for collecting water, then as they fill, you can pump them out using the same submersible fecal pump. Often the pump is installed permanently in such pits and operates automatically using a float switch.

- If the farm has a submersible sewage pump, then it will always help cope with the consequences of the elements - basements or living quarters, wells, low-lying folds of the site, etc., flooded due to floods, heavy rains, sudden melting of snow or man-made accidents. The presence of a shredder allows you to not worry that dirt or debris that gets into the pump will hinder its operation.

- If the site has a storm and (or) drainage system, then the pump can serve a good purpose here too. With its help, it is possible to prevent wells or collectors from overflowing, for example, during periods of prolonged rain, when the drainage capacity of the wells is simply not enough. It may also be useful for emptying the last chamber of the septic tank - with its help, water is pumped out to filtration fields or even for some useful purpose.

Special bioactivators will help in purifying water in septic tanks and cesspools.

It is in vain that many owners of private houses ignore the use of special biological additives for autonomous sewers.

- are able to quickly process organic waste into water and harmless mineral sediment, improve the drainage capabilities of storage wells, and eliminate unpleasant odors. More details about this can be found in a special publication on our portal.

- Artificial reservoirs created on the site require periodic cleaning and replacement of water. And in this case, a submersible fecal pump may well come to the rescue, which is not afraid of mud deposits at the bottom.

Finally, in the case where a natural reservoir - a lake or river - is located in the immediate vicinity of the site, a pump can also be used for irrigation purposes. Of course, with its very high productivity, there is no point in supplying water directly to irrigation installations, but filling watering containers will not take much time. In a word, this useful device

There will definitely be a use, not even considering its main purpose.

How to choose a fecal submersible pump?

If you decide to purchase a fecal submersible pump for a cesspool, your choice should be guided by a number of certain criteria.

- Pump supply voltage and power consumption. Almost all household-grade submersible fecal pumps are designed to operate from a conventional 220 V 50 Hz network. Power indicators predetermine the remaining operational characteristics of the equipment - its productivity, the pressure created, the potential for pumping liquids of high viscosity or with a large amount of contaminants.

For country conditions, a pump with a power of up to 500 W is usually sufficient. But if you plan to regularly maintain the autonomous sewer system in the house permanent residence, then it is better to choose a device with a power of about 1 ÷ 1.5 kW.

As power increases, energy consumption also increases, of course. But if the pump has good performance, then long-term operation is not expected - usually even for pumping large volumes of several cubic meters of water, 5 ÷ 10 minutes are enough, and in such a short period of time it will not “wind up” the electric meter to any degree.

- The performance of a submersible pump is its ability to pump a certain volume within a unit of time. Typically for drainage and sewage pumps this figure is expressed in liters per minute. Even the most “weak” pumps, as a rule, cope with a volume of about 150 l/min. The performance of pumps with a power of 1.5 kW or more can reach 500 ÷ 650 l/min! Half a ton per minute – even a large container won’t take much time!

- Created pressure. This is a measure of the fluid pressure created by the pump at the outlet. Typically, for pumping equipment of this class, this value is expressed in meters of water column. This pressure should be enough to lift liquid waste from depth and deliver it along a horizontal section of the pipe (hose) to the disposal site. We must not forget about the horizontal section, especially since we often have to work with viscous waste, and the hydraulic resistance of the pipe can be quite large. For an approximate calculation, you can focus on the following ratio - 1 meter of created pressure will ensure the movement of liquid along a 4-meter horizontal section.

Typically, household-grade submersible fecal pumps are capable of creating a pressure of 10÷15, sometimes more, meters.

- Case material. Preference should still be given to metal models - they are more reliable. But it must be either cast iron or high-quality stainless steel. Wastewater- this is a very aggressive environment from a chemical point of view, and ordinary steel will not last long in such conditions.

Pumps in different housings - cast iron, stainless steel and plastic

Pumps in different housings - cast iron, stainless steel and plastic Cast iron, of course, is cheaper, but its pumps are quite massive, and this will need to be taken into account when choosing a suspension - rope, cable or chain. In addition, cast iron should be handled with a certain degree of caution - the alloy is brittle and can crack under an accentuated impact.

Stainless steel pumps are lighter and look prettier (if that matters in this case...). But such improvements certainly affect the cost of the model.

Plastic pumps cause a lot of controversy, and have not yet won full trust from users. It is clear that modern polymers often even surpass metals in their strength properties, but certain concerns still remain.

- If you plan to automate the pumping process, or to insure yourself in case of your own carelessness, it is better to choose a pump immediately equipped with a float water level sensor with a switch.

Automation connected to the float switch will prevent the pump from running dry after the well or pit is emptied

Automation connected to the float switch will prevent the pump from running dry after the well or pit is emptied If you plan to use the pump only in manual mode, then you can save money on this option.

- The pump cannot be lowered to any depth relative to the water surface - this parameter is also specified in technical specifications products.

- For any pumps intended for pumping dirty water, and for fecal ones in particular, the permissible size of solid inclusions is important. It is usually indicated in millimeters, for example, up to 30 mm - this is considered a good indicator.

- If hot wastewater is to be pumped, the pump must be designed for such operating conditions. Typically, most fecal submersible pumps are designed for cold water– with temperatures up to 35 °C.

- The pump is cooled externally by the liquid in which it is immersed. But as it is pumped out, the power unit may protrude above the water and begin to heat up. Therefore, built-in pump overheating protection is never superfluous - when the stator windings reach a certain critical temperature, the electrical circuit will be interrupted.

If there are frequent interruptions in the stable power supply in your area of residence, then the model should have protection against power surges or an extended range of permissible

- The reputation of the equipment manufacturer is important. Of course, it is best to choose models from well-known brands, foreign and domestic, and be sure to clarify how the region is organized service maintenance and how actions will be taken in the event of a complaint about the purchased pump - immediate replacement, refund, sending to the factory for repair, etc.

Unconditional authority is enjoyed by fecal pumps of the brands “Wilo”, “Grundfos”, “Unipump”, “Dzhileks”, “Pedrollo”, “Herz”, “Vikhr”, “Metabo”, “Calpeda”, “ESPA”, “Quattro Elementi” , “Sturm”, “Sprut” and others. But this must be a truly original product, and not a cheap knockoff. Therefore, it is necessary to purchase such equipment exclusively in specialized stores, after carefully reading the accompanying documentation.

Below will be given short review popular models of submersible fecal pumps

Review of fecal pump models

| Model name | Illustration | Brief description of the model | Approximate price level |

|---|---|---|---|

| "Dzhileks Fekalnik 255/11 N" (Russia) | Products of a Russian company, from development to production. Stainless steel body. Pump power – 1100 W. The created pressure is 11 m of water. Art. Productivity – 255 l/min. Permissible immersion depth is 8 m. Float switch. Overheat protection. Weight – 7.5 kg. Stepped connection pipe for ¼, ½ or 1 inch hoses. The permissible size of solid inclusions is 35 mm. | 8200 rub. | |

| "STURM WP9709SW" (brand – Germany, assembly – China) | A fecal pump with a grinding device that has earned a lot of high ratings from users. Cast iron body. Power 900 W. The created pressure is 12 m of water. Art. Immersion depth – up to 5 m. Float switch. The permissible size of inclusions is up to 36 mm. Weight – 17.6 kg. Outlet pipe – 2 inches. | 8500 rub. | |

| "Whirlwind FN-1100L" (brand – Russia, assembly – China) | High-quality fecal pump developed in Russia. Combined body – stainless steel + cast iron. Power – 1100 W. The created water pressure is 9 m. Productivity – 233 l/min. Grinding mechanism. Float switch. Internal anti-air valve. The pipe is 2 inches. The weight of the device is 17.6 kg. | 11600 rub. | |

| "QUATTRO ELEMENTI PROF Sewage 1100F Ci-Cut" (brand – Italy, assembly – China) | An excellent model developed by a famous Italian company. The body is a combination of stainless steel and cast iron. Power – 1100 W. Productivity - 233 l/min. The created pressure is 7 m of water. Art. Knife chopper. Float switch. Built-in overheat protection. The maximum size of solid fractions is up to 15 mm. Weight – 19 kg. It is famous for its durability and low maintenance requirements. | 14,000 rub. | |

| "Herz WRS25/11-180" (Germany) | High quality pump designed for the most extreme operating conditions. Body – stainless steel + cast iron. Power – 800 W. The created water pressure is 14 m of water. Art. Capacity – 260 l/min. Maximum immersion depth is 8 m. Knife chopper made of tool stainless steel. The maximum water temperature is up to +40 degrees. Weight – 28 kg. The outlet pipe is 2 inches, on a flange that allows changing the flow direction. | 13000 rub. | |

| "Pedrollo BC 15/50" (Italy) | One of the leaders in quality and high performance. The body is stainless steel, the working chamber is cast iron. Supply voltage – 380 A, drive power – 1100 W. The created pressure is 14 m of water. Art. Increased productivity – up to 800 l/min. The maximum diving depth is 5 meters. Float switch, all degrees of protection. The upper permissible temperature limit is +40 degrees. The pipe is threaded, 2 inches. Pump weight – 15 kg. The permissible size of solid inclusions is up to 50 mm. | 28800 rub. | |

| "Wilo Drain TP 50/TP 65" (Germany) | Top quality model, German design and production. The power unit housing is stainless steel, the working chamber is cast iron. Drive power – 1000 W. The created water pressure is 9 m of water. Art. Productivity -433 l/min. Maximum diving depth is 10 m. Float switch is optional, it is possible to purchase a model without it, but a special plug is provided for connection. The permissible size of solid inclusions is up to 44 mm. The impeller is single-blade centrifugal or free-vortex. | 25,000 rub. | |

| "Grundfos SEG 40.09.2.1.502" (Denmark) | Fecal submersible pumps of the highest quality category. The body is cast iron. Drive power – 1300 W. The created pressure is 15 m of water. Art. Capacity -250 l/min. Flange adapter for 2" pipe. All modern levels of protection. Built-in water level switch that does not require an external float system or external automation unit. Possibility of quick adjustment of the gap between the impeller and the housing. Shortened shaft, reducing loads on the bearing block. Efficient waste shredding system. | 47,000 rub. and higher |

Video: operation of a fecal pump with a grinder - “Grundfos SEG”

A little from personal experience

First, briefly about the background of the issue.

The scene is the city of Bendery, Moldova, Transnistria. The distance from the house to a fairly large river by European standards, the Dniester, is about 500 meters, but the height difference is quite significant, about 6 meters.

We bought the house 14 years ago - in September 2002. Before that, no one lived in it for a couple of years. Among the “conveniences” there was only a tap in the house - there was no toilet, no bath, no shower. The drainage pit is located in the yard, 3.5 meters deep, concrete walls and free drainage from below. The top is closed with a cast iron hatch. By the time of purchase, it was, of course, practically empty.

In the very first month of residence, all communal amenities were created, including a bath, toilet, washbasin, and an automatic washing machine was installed - all of them were tied specifically to this pit. The only exception was the kitchen - due to the peculiarities of the location of the premises of the house. The drain from the kitchen was led into another hole, which serves as a storm well and is located near the gate to the courtyard.

Why is this being told? The fact is that over 12 years, the intensive use of water by a family of 4 people has never led to an overflow of the sewage pit. Moreover, someone took a bath - almost every day. But two years ago, while carrying out small-scale work in the bathroom, I decided at the same time to call a sewer truck and clean out the cesspool. There was no good adviser nearby at that time - DO NOT TOUCH THE PIT until it copes with its drainage functions. And I wasn’t smart enough to read forums on the Internet - the ladies were given a lot of recommendations of the same kind in this regard.

In a word, after the pit was pumped out to the bottom, serious problems began. Just a couple of months later, water began to seep up through the hatch. Call the car again - and history repeats itself with enviable regularity. Apparently, the hydrological balance of the well and the surrounding soil was disrupted, and drainage qualities dropped several times.

It’s also a shame that the arriving car literally pumped out only water, since there was a minimum of solid waste. I have been using bioadditives for a long time, and the bacteria work well, so that practically no sludge accumulates.

Paying a lot of money for pumping water is, of course, unreasonable. Each call costs 200 of our rubles (the approximate ratio to the Russian ruble is 1:5.5, that is, one pumpout costs about 1,100 rubles). And after a year and a half of torment, it was decided to distill the water from the sewage pit into the storm pit, into which, as already mentioned, the kitchen sewer was also drained. From there, the water goes into the drainage “with a whistle”, and an approximately stable level is always maintained in the hole.

Laying pipes for overflowing water by gravity was considered unprofitable, since the entire yard is paved concrete slabs(still from the old owners). And so a fecal submersible pump was purchased.

The model cannot be called a brand name, but this is the peculiarity of our unrecognized region - it is very difficult for high-quality equipment with a factory guarantee to reach here. The packaging indicated that it was made in Russia, Chelyabinsk, but no accompanying documents were included, although the pump was purchased at the largest specialized plumbing store in the city.

However, the price of the issue was very satisfactory - exactly 1000 of our rubles (in Russian rubles, therefore - 5500 rubles).

And with the help of this pump, water has already been pumped from one pit to another four times - that is, 800 rubles for calling a sewer truck have already been “recovered.”

The last time this was done was this morning, June 4th. There were heavy rains for more than a week, and the cesspool “made itself felt.”

The pumping process has already been worked out and can be completed by one person in literally 15–20 minutes.

| Illustration | Brief description of the operation performed |

|---|---|

| Here it is - the cast-iron hatch of the cesspool. Located in the center of a paved courtyard. |

| The yard has a fairly significant slope towards the gate, and in front of the gate there is a storm drain covered with a grate. It leads to the second pit, where we will pump water from the first. The straight line distance between the pits is about 12 meters. |

| The slight “debacle” was caused by the fact that work had begun on installing a new plastic hatch on the storm pit - there was a wooden one there, already pretty rotten. Work was temporarily suspended due to prolonged rains. The hatch frame has already been installed, but is not yet fully embedded in the mortar. |

| This is the hatch itself, awaiting final installation. |

| From the very beginning it was decided not to use a long flexible sleeve, in order to avoid twisting, fraying, etc. A set of three-meter sewer pipes 50 mm - and it turned out to be more profitable in terms of money. The cat appears in the frame for the second time: this is not because I like to “post cats” - this weasel just loves to “help”, no matter what I do. |

| For direct connection to the pump, a 50 mm piece of flexible hose was used, the length being the depth of lowering the pump into the pit. By the way, the standard clamp with a bolt that came with the pump turned out to be of little use - it was replaced with a worm clamp. On the other side, the hose ends with a 90° bend - this time for connection to the pipe. |

| During the second pumping, a small emergency occurred - a strong pressure at the point where the flow direction changed tore off the outlet from the socket of a straight section of the pipe. At that time, it was still possible to avoid an “odorous shower,” but then measures were taken - the connection is fixed with self-tapping screws: they do not take long to remove or screw into the drilled holes. |

| Assembling a straight section is a matter of one minute... |

| A flexible sleeve is also used on the opposite side. This is due to the fact that it is necessary to insert the pipe into the storm drain channel. This measure is temporary, and after the hatch is ready, a straight structure ending in a rectangular outlet will be used. |

| The storm grate is raised and the pipe is inserted into a channel that goes into a storage and drainage well (pit). |

| To suspend the pump in a cesspool, the most inexpensive option is used - a 12 mm nylon rope - this will be quite enough. For ease of lowering and lifting, knots are tied on it. The loop will be suspended from a piece of steel angle placed on top of the open hatch. |

| Everything is prepared - you can open the hatch. Yesterday the water came out. Today the level has dropped somewhat, but is still critical. Any use of even 50 liters of water will result in overflow. |

| Carefully releasing the rope (under no circumstances - not by the power cable!), lower the pump into the sump pit. |

| Fully ready to start pumping. The procedure was initially planned to be carried out in visual control mode, so we did not bother with the float switch. |

| We plug in the power cable and watch the process. |

| The hum of the pump is practically inaudible, only a slight vibration. The water level is rapidly falling before our eyes. |

| At the other end of the “main”, the flexible hose was inflated from the pressure of the pumped water. |

| The pumping lasted 8 minutes. About three cubic meters of water (the hole expands much from the neck down) were transferred to the drainage well. Now for 2-3 months there will be no problems. |

| It is advisable to flush the pump immediately. Place it in a container with water and turn it on for 10÷15 seconds. At the same time, we supply water into the container through a garden hose. The inside of the working chamber of the pump and at the same time all the hoses and pipes are washed. |

| The cesspool hatch is in place. We disassemble the pipe connections and put them in the garage for storage until next time. |

| We rinse the pump and the hose attached to it from above thoroughly with water pressure, and can also be sent for storage. |

So, the whole procedure took about 15–20 minutes, without the involvement of assistants, and this also takes into account pauses for photography. By the way, driving a sewage disposal truck into the yard and its work sometimes took even more time.

Conclusions:

- First, I don’t regret purchasing a submersible fecal pump, since I got the opportunity to periodically clean the cesspool of water on my own. The call for a sewage disposal truck is postponed until a very distant future, until the moment when circumstances force the pumping out of bottom silty sediments. But, judging by observations, such a need is not expected in the next few years.

- And the second one. Guided by my own experience, I will take the liberty of giving advice - do not pump the cesspool dry with a sewage disposal machine while it is able to cope with water drainage on its own! I won’t let sewage trucks near my second, “working” well at any cost!