Round wood and copper crafts are good to make on a small home lathe. What do a lathe and a drill have in common? For an ordinary person, far from production, nothing. But for the modern Kulibin, this is a real Klondike of ideas. A person with imagination and skillful hands can easily make his home lathe from a drill.

Purchased or homemade lathe - which is better?

The cost of small factory-made lathes makes one think of an alternative solution to this problem. A self-assembled turning machine can be much cheaper. To bring your idea to life, the most expensive thing you need to buy is a drill or a hammer drill that has the function of a drill. Consider the option of manufacturing a lathe from for a private home business. The simplicity of manufacturing such a necessary and useful equipment is amazing. The simplest lathe can be made in one day "on the knee". In the manufacture of the most unpretentious lathe, you will need wooden bars, plywood, tin, good glue and other materials.

Materials for the manufacture of a lathe

Before thinking about how to make a lathe, you need to calculate whether the cost will turn out necessary materials more than the cost of the factory device? To do this, it is better to look at a list of all the necessary materials and equipment, determine what is available and calculate how much you need to spend on the missing items.

A set for a lathe from a drill is as follows:

- electric drill;

- a sturdy table or workbench;

- at least three clamps;

- self-tapping screws;

- bolts, screws and nuts;

- files;

- incisors;

- sandpaper.

But if your home business has grown to require high productivity and precision steel fabrication, then you need to fork out and get an industrial lathe with a powerful electric motor, a rigid bed and tooling mounted on it.

What is a lathe made of?

Any lathe has the following main components in its design:

- Lathe bed. Foundation in machine tool building.

- Headstock with a power unit, in this case a drill.

- Rear grandma. Its location along the axis must correspond to the axis of the headstock. Otherwise, marriage will come out during work.

- A stop is required to install the cutting tool. Its location should be as close as possible to the workpiece set for processing. It is desirable to make such a support table that will allow you to safely work on a homemade lathe from a drill.

- The machine bed determines the main location of the lathe units and ensures the reliability of the entire unit. A powerful bed, equipped with reliable legs with correctly installed and coaxial nodes, is a full-fledged lathe. A small bed can be installed on a massive table or workbench. The assembled lathe from a drill on a bed of this type is easy to carry and transport.

- Purchased factory equipment will make it easier to work on a lathe from a drill.

It should be noted that the processing of materials on the resulting device will be limited. On such a home-made device, you can process wood, copper, aluminum and its alloys, that is, any soft materials. On a do-it-yourself lathe, a steel part cannot be machined from a drill.

Work process

A piece of thick plywood works well as a bed. It has a flat surface, which will help in coaxial installation of the headstock and tailstock. The drill can be fixed by any available method. The main condition is that it must be hardwired. In our case, consider an example using clamps.

Let's prepare the main element of power traction. For the convenience of assembling a homemade lathe from a drill, we will prepare a clamping fixture for fixing the drill. Let's take a metal clamp, having previously altered it a little.

It is necessary to fix the clamp, which will later clamp our drill. Let's fasten it to the frame. Clamp the drill with a clamp attached to the clamp. Thus, a rigidly fixed headstock with a power unit was obtained.

Support for lathe

In a similar way, we will make the tailstock of the lathe from a drill. It is necessary to install the tailstock using a second clamp, always in the same axis as the front. For ease of operation, a bearing with a pressed-in axle, sharpened under a cone, is perfect for the tailstock. A cartridge can also be used as a fastener for a part.

We need the third clamp for the support table. This is the so-called caliper by professional turners.

For the convenience of moving the caliper along the axis of the part, it is desirable to make a rigid groove on the base of the bed. The manufacturing method is as follows:

- Two even strips are cut out of plywood along the length of the lathe.

- Then they are rigidly attached to the frame.

- A caliper base is inserted between them, ensuring its reliable movement along the axis.

Such a simple and reliable fixture will provide ease of processing parts.

The ideal caliper for a lathe from a drill is one when the caliper has the ability to move both along the axis of the lathe and across it. With it, the turner will be able to freely hold the cutter during processing. The caliper is brought close to the part, which ensures complete safety in operation. If the stop is far from the workpiece, then the turning tool can be pulled out of your hands.

Tool required to machine the part

You can process a part fixed in a lathe with cutters. This is especially true for those parts that consist of various alloys. The cutter is securely mounted on a support, which allows you to grind copper, brass products and parts from other soft metals. As a cutter for processing a wooden workpiece, a sharpened locksmith's file - a rasp is suitable. Will cope with the work and file. A well and properly sharpened piece of an automobile spring also works great as a cutter.

How to fix a large diameter workpiece on the machine?

To attach large-diameter workpieces to a lathe, you will have to stock up on a plan with a washer, which is attached to the chuck of an electric drill. Its use makes it possible to grind parts of large diameters.

On a home-made machine, you can carve balusters for stairs, make wooden dishes with your own hands and at your discretion. The machine is perfect for the manufacture of round candlesticks, and indeed any round wooden product and products made of soft types of metals.

How to replicate wooden products from blanks?

To replicate balusters to a staircase under construction, for example, you can use a copier. What is a copier and how to work with it? Everything is ridiculously simple. The necessary product for the stairs is being made. An additional device is made from a drill to a compact wood lathe, on which a baluster made in exact dimensions is attached. The second copy is made according to existing sizes.

Many have seen craftsmen working on duplicate keys. A "native" key is inserted into the copier, and all the bulges on the workpiece duplicate its bulges. There is no need to constantly measure the part. The machined part is an exact copy of the original. The principle and approach are the same.

Drawings of a lathe from a drill

By adding a homemade lathe with just a few details, you can significantly expand the functions of such equipment. With it, you can paint a part or carve a twisted mesh along the entire length of the workpiece. You can use the unique capabilities of a drill not only in a lathe. It is possible to make on the same frame and which will work no worse than the factory one. The diameter of the drill depends on the chuck in the drill. Adapters or drills with shanks suitable for the cartridge will help to increase the diameter. Making a milling machine, having learned and understood the capabilities of a drill, will not be difficult.

Electricians will appreciate the use of a homemade lathe when winding windings for transformers at home.

In conclusion, we can state: a seemingly simple power tool with competent and correct use can expand its capabilities and become an indispensable equipment in home production. The main thing is that before you try and learn how to make a lathe, you need to be patient.

Inexpensive and powerful enough mini wood lathe for making small souvenirs or minor repairs you can do it yourself. The basis will be a conventional two-speed drill with a power of at least 500 watts. The following is step-by-step instruction manufacturing a machine that can produce products with a maximum size of 160x400 mm.

Machine capabilities

There are many uses for a drill machine besides turning:

- fixing the emery stone, using the stop, you can sharpen knives, drills, chisels with your own hands;

- at a right angle along the edge, you can process parts made of plexiglass, plexiglass or wood. It is necessary to install a plywood circle with sandpaper in the cartridge, and instead of the stop, a wooden stand is attached, on which the part is placed;

- using a rubber wheel and a set of sandpaper, you can polish and grind any parts made of wood or metal;

- if you fix the felt disk, any metal utensils are polished to a perfect shine.

Housing and headstock

The rack (body) for the machine is easy to make from a board or thick plywood. A round slot is made in the body for the drill itself (the size must be such that the tool fits snugly) and for the tightening bolt. After that, a groove is sawn with a width of not more than 2 millimeters.

The rack is attached to the base with metal corners. A drill is inserted into the slot and tightly tightened with a screw.

More reliable racks for attendants are obtained from textolite or metal sheet. When assembling the case, it is necessary to achieve alignment of the slots in both racks.

The central part of the headstock is made of a metal rod tapering into a cone at one end. An M8 thread is sawn in front of the cone for 15 mm. A nut is screwed onto the rod, a cone and a small segment of the rod peep out of it.

Tailstock with fixed center

A wooden blank of the same shape as for the headstock is needed. The middle is made of hardened steel grade U8. A sleeve is machined from it with its own hands, inside which a thread is made with parameters M14x1.5. On the side, a move is made for a locking bolt with an M6 thread. An M24x3 thread is made from the edge of the sleeve to install a nut that will hold the sleeve. A suitable flywheel is removed from the water tap.

Components of the incisal stop are made of steel. A bracket is made from a 6x10 mm metal strip. A cylindrical mandrel is made with a diameter of not more than 15 millimeters, and the edges of the bracket are welded to the tube. Also, an emphasis in the form of a corner is attached to the rack. The mechanism is bolted to the workbench. To screw in the bolt, a special nut with a wide shoulder is made, which is attached to the bottom cover of the workbench with screws.

Workpiece clamping

In order for the product to turn out to be of high quality, the wooden blank must be dried. Before mounting in a lathe, it should be trimmed or turned, leaving about 3 mm for processing in the machine. Two small recesses are made at both ends, the edges of the nut are inserted into them. The blank is placed between the middle of the attendants and is firmly pressed with a stopper.

When the workpiece is installed, do-it-yourself incisal stop is placed with an interval of no more than 2 cm to the workpiece. The working surface of the cutter should be located at the height of the center of the blank.

For woodworking on a do-it-yourself machine, the following types of cutters are suitable:

- peeling or semicircular for preparatory work;

- flat for fine finishing;

- cutting and cutting.

Instead of incisors, sharpened wood chisels are suitable. You can make them yourself from files, which are brought to the required profile shape with the help of a grindstone.

- It is better to process wood on a homemade lathe by turning on the drill at low speeds.

- During operation, the cutter should be at an angle of 25-30 degrees to the blank.

- The final shape is achieved in several approaches.

- Grind and polish the finished product at maximum speed using sanding paper (numbers over 60 for grinding, over 200 for polishing).

- The polished product is varnished or painted directly in the lathe. And only the dried up is cut and removed.

The desire to make useful things for the interior of an apartment with your own hands can be realized in a small workshop. Some of its equipment is easy to make yourself from a standard set of conventional tools that almost every owner of a private house has.

Consider one of the design options for such a device. We hope that our tips will help the home craftsman make a homemade woodworking lathe from an electric drill, use it reliably and safely.

Based on my own experience, it can be argued that many teenagers like to engage in the creative process on a lathe, turn simple kitchen utensils, tool handles, as well as sports nunchucks, nesting dolls and even chess out of wood.

The design of a lathe from a drill

The first such device was made by me more than twenty years ago based on the materials of one of the Do-It-Yourself magazines. Only photographs remained from him, from which I present the drawings with my comments.

They are additionally illustrated by pictures of finished parts, photographed from different angles. They will allow you to better understand the process of making lathe parts from a drill.

To work, you will need to make:

- the headstock into which it is inserted;

- tailstock with a movable locking center;

- stop for the cutter;

- tip-clamp for fastening the workpiece in a drill;

- machine bed;

- clamps or other fasteners.

The main thing is a clear, reliable fastening of all parts on a common stable frame. It will ensure the correct rotation of the workpiece, it can be made of metal or wood. I used a thick, wide workbench board. It is permissible to mount all parts with clamps on a solid table, as shown in the drawing.

In the picture, a single red axis of rotation is specially highlighted. Its observance in the horizontal direction will ensure optimal processing of the workpiece without beats and unnecessary swings.

It is set by the position of the height and direction of the axis of rotation of the drill chuck with the center of the tailstock, as well as the correct fastening of the wooden workpiece.

Headstock

It was decided to use multilayer birch plywood and aluminum corners as the material for its manufacture, as shown in the drawing. You can also use thick getinax or fiberglass plates. Their total thickness should ensure that the drill is securely held by the socket for attaching the additional handle.

To do this, a hole is cut in the center of the workpiece. It can be drilled with an annular drill. I cut in multilayer plywood with a regular hand jigsaw after fastening the boards with corner screws. Then I finished the surface a little with a round file.

On one side of the headstock, a slot about two mm wide is made with a saw. It is needed to fix the drill in the socket due to compression with a pin. For the latter, you will need to create a cavity: drill in a vertical direction or simply cut it with a knife, having previously disassembled the mount.

The fixing screw of the stud in the body of the headstock is inserted through the drilled hole, and the corners are fixed to the base board with screws.

Tailstock with adjustable center

The body of the mount is made using the same technology as before. Only the central hole is cut along the outer diameter of the movable center sleeve. It must move freely along the axis due to the rotation of the handwheel handle and be locked with the screw of the locking handle, as shown in the drawing.

However, the locking unit in my headstock design is somewhat different: not lateral, but horizontal compression of the thread with a lock nut is used. She just has to push wrench.

Compare both methods and choose the one that suits you best.

A home craftsman cannot make a center and a sleeve with his own hands without a metal lathe. I ordered it from the turner in size.

The center surface is the base base for the rotation of the wood workpiece. It needs to be ground and hardened, you can even lubricate a little. This will reduce friction losses.

Instead of a manual spindle rotation wheel, as shown in the drawing, I installed an ordinary valve handle from an old water faucet, grinding off a seat from the end of the thread under it with a file.

You can even just weld a bar into the center, but then the fastening design will become non-separable.

Ways of fastening the workpiece in a lathe

Turned parts can be long or short, wide in the form of a bowl. They are installed in different ways.

Fixing long workpieces

The installation method is shown in the very first drawing. A tip of a special design is inserted into the drill: a rod with a diameter of 8 ÷ 10 mm with a trident at the end.

For its manufacture, you can use a threaded stud, a simple and wing nut, which are tightly crimped on the threads with a wrench. The end of the stud is ground into a cone. 10 ÷ 15 mm recede from it to the edge of the lamb.

This part will be included in the end of the workpiece. In it, a hole is drilled in the middle to a depth of about 10 ÷ 15 mm to center the workpiece with a pin and a cut is made, which includes the lamb ears that transmit the rotation of the cartridge.

It is quite acceptable to simply make a central slot in the hairpin and weld a flat trident there.

On the reverse side, a long workpiece, when rotated in a lathe, is held by the center of the tailstock.

Mandrel for short parts

The upper part is clamped in the drill chuck, and a wood blank is inserted from the back of the mandrel. Through the drilled holes, it is fixed with screws in the tubular cavity.

It must be taken into account that when the workpiece is fastened through the center of the mandrel without a tailstock, lateral loads act on the bearings of the drill. Therefore, it is impossible to create big efforts.

Such a design of the mandrel allows you to cut out even the internal cavities of parts, make goblets, bowls, salt shakers and similar utensils.

Cutter stop design

The corner is welded to the bar and inserted into a vertical tube-rack, in which it is rigidly clamped with a locking screw. A thick wire bracket is welded to its lower part. It is fixed in the base with a clamping bolt and nut inserted through the hole in the tabletop.

Due to the length of the bracket, the stop can be moved to different points of the base, and the loosened stopper of the upper shelf allows it to be adjusted relative to the axis of rotation of the lathe.

Preparation of blanks

Wood should be well dried and selected without cracks. Good products are obtained from deciduous trees: birch, apple, pear, oak and other fruit trees. The hardness of the material affects the speed of its processing.

Before installing the workpiece in a lathe, it must be given a cylindrical shape with an ax, planer, knife. This will significantly reduce the processing time, reduce the load on the electric motor.

Under the centers of rotation of the headstock and tailstock in the workpiece, it is necessary to drill holes along the ends of the prepared cylinders, and for the trident, make a cut.

Short blanks for fastening in the mandrel with screws must be made with a protrusion that fits snugly into its cavity.

Tools

To process a rotating workpiece, you will need a tool - cutters. At first, you can get by with ordinary chisels, achieving their good sharpening.

With the acquisition of experience, cutter designs will be required:

- semicircular - peeling, roughing;

- flat for precise processing: trimming, cutting, alignment.

They are easy to do with your own hands on an emery machine or just buy a ready-made kit in a store.

Lathe Features

Initially, I used a Soviet-made drill with a thyristor speed control and a power of only 300 watts. She worked for me until the wear of the collector mechanism for more than 30 years under various loads, including extreme drilling concrete slabs. Perforators at that time simply were not on sale.

For unhurried small crafts, this power is enough. But for normal operation, it is better to use the design of a modern drill for at least 800 watts. The difference will immediately affect.

For many types of work, high rotation speeds are not needed: you have to use the regulator. In this mode, the load on the engine increases, and the reserve of its power, and of the entire structure, is simply necessary.

In order to increase the efficiency of the lathe, I installed instead of a drill.

This made it possible to grind long and durable workpieces like shovels and other garden tools.

To fasten a wooden blank to the engine, it was necessary to make a sleeve with fixation with a locking screw on the rotation shaft and an E-shaped tip inserted into the center of the wood saw cut.

All the photographs show that my lathe was made a long time ago, and is stored in a workshop where moist air penetrates. Within a few years, there were clearly visible signs of corrosion. Do not allow such cases with your instrument.

If you think about creating a design for a woodworking lathe not from a drill, but due to an asynchronous motor, then it is better to use a three-phase voltage of a standard value of 380 volts to power it. Power loss will be minimal.

For a single-phase network of 220 V, you can connect, embedded in the design of a three-phase asynchronous motor. Such devices are commercially available at a reasonable price. They are convenient to use on different engines.

equipping workplace turner, pay increased attention to safety measures and the selection of electrical protection. Be sure to connect the electric motor only through those associated with short circuits and overloads.

Determine according to local conditions. But in critical situations, protection is not superfluous.

The design of the tailstock can be improved by including a thrust bearing in the center, for example, size No. 607. The friction spent on the rotation of the workpiece will immediately decrease, and its combustion will be excluded.

The carved figures created by the hands of a master on a lathe delight, and I want to do something similar. A lathe from a drill mounted on a bed from a foot sewing machine will allow you to get a souvenir from an inconspicuous bar. The tree is easy to process. For metal processing homemade machine should be more thorough. A do-it-yourself lathe from a drill will not be left without work.

The carved figures created by the hands of a master on a lathe delight, and I want to do something similar. A lathe from a drill mounted on a bed from a foot sewing machine will allow you to get a souvenir from an inconspicuous bar. The tree is easy to process. For metal processing homemade machine should be more thorough. A do-it-yourself lathe from a drill will not be left without work.

Lathe device

Even before the advent of high-speed electric machines, wood lathes already existed. Rotation could be transmitted to the spindle from the pulley by belts. The big wheel was even rotated by hand. A lathe from a drill, driven by an electric motor, became high-speed, but the principle of operation, invented several centuries ago, remained the same. On a massive welded frame with a well-thought-out reliable fastening, the machine can process even soft metals - copper, aluminum and similar alloys.

Even before the advent of high-speed electric machines, wood lathes already existed. Rotation could be transmitted to the spindle from the pulley by belts. The big wheel was even rotated by hand. A lathe from a drill, driven by an electric motor, became high-speed, but the principle of operation, invented several centuries ago, remained the same. On a massive welded frame with a well-thought-out reliable fastening, the machine can process even soft metals - copper, aluminum and similar alloys.

The wooden blank inserted for processing into the lathe must have a round shape. The ribs must first be folded so that the cutter runs smoothly on the surface.

For processing wood and plastic, you can make a simple design that is easier to hide in a secluded corner, even in an apartment.

The diagram shows a homemade wood lathe from a drill. On a stable platform with an axial through slot, made in any convenient way, equipment is installed. A plate fixed to a suitable structure is called a bed. This is the basis of the future machine. The size of the bed depends on the length of the workpieces, and the place to place the work units:

The diagram shows a homemade wood lathe from a drill. On a stable platform with an axial through slot, made in any convenient way, equipment is installed. A plate fixed to a suitable structure is called a bed. This is the basis of the future machine. The size of the bed depends on the length of the workpieces, and the place to place the work units:

- headstock or leading center,

- tailstock,

- caliper or handbrake.

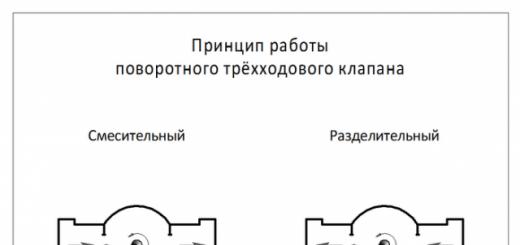

If the engine that provides rotation of the leading part is used in the form of a drill, then the tool must be firmly fixed with special clamps. A holder in the form of a faceplate is inserted into the chuck, with which the end of the workpiece is attached. The headstock can have one freedom of movement - along the axis. On lathes from a drill for metal, the headstock is welded tightly to the frame.

The center of the tailstock and the front are at the same height above the bed and along the axis. The installation accuracy is important and controlled in relation to the slot on the table plane. The tailstock necessarily has one degree of freedom. The inserted workpiece between the centers is clamped, and after that the rear assembly is fixed.

The center of the tailstock and the front are at the same height above the bed and along the axis. The installation accuracy is important and controlled in relation to the slot on the table plane. The tailstock necessarily has one degree of freedom. The inserted workpiece between the centers is clamped, and after that the rear assembly is fixed.

It is important to set the workpiece in the center so that it does not hit during rotation.

The handpiece is called the middle insert, which is fixed under the workpiece. Sawdust flies into it, but the main purpose of the assembly is to support the cutter on the working side. The master brings the cutter to the rotating rod, leaning on the edge of the handbrake, which is located almost close to the line of rotation. The stop must have freedom of movement perpendicular to the longitudinal axis, it is removed when the workpiece is installed.

The handpiece is also therefore adjustable vertically, it should be as close as possible to the surface to be machined so that the turning tool rests on the rib. With a large lever, it is difficult to hold the tool and it can be pulled out with serious consequences. When turning conical surfaces, the handpiece is set at an angle, parallel to the cone.

When working on a lathe, you need to remember your own safety. Be sure to use protective goggles. Clothing should fit snugly. But the hands must be open to feel the instrument.

A lathe from a drill with a commutator motor is not a very good design. Without a constant load, the motor picks up speed, goes "peddling". Therefore, an electronic unit is provided to maintain a constant rotation speed. If there is no such device, a gearbox is installed for safety reasons. Sometimes designs with high-speed mechanisms are connected through a belt drive. On the basis of a drill, factory-made lathes cost about 5,000 rubles.

Let's create a machine with our own hands

On a solid, stable base such as a workbench, a turning attachment for a drill is attached, representing the headstock. It should create conditions for installing the spindle so that the holes with the back are coaxial. As an example of creating a basis, you can use the drawings of the proposed nodes.

An electric drill, which simultaneously serves as a headstock and an electric rotation drive, is fixed on such a surface with a clamp and a clamp fixed on the neck of the tool. However, it is possible to mount the drill on a hill above the bed, and then the second attachment point rises to the same height. There are many options on how to make a lathe from a drill. The main thing is that the principle of axial centering and reliable fixing of the workpiece is observed. It is for the stabilization of each node that it is important to think over the fasteners of clamps and drills.

An electric drill, which simultaneously serves as a headstock and an electric rotation drive, is fixed on such a surface with a clamp and a clamp fixed on the neck of the tool. However, it is possible to mount the drill on a hill above the bed, and then the second attachment point rises to the same height. There are many options on how to make a lathe from a drill. The main thing is that the principle of axial centering and reliable fixing of the workpiece is observed. It is for the stabilization of each node that it is important to think over the fasteners of clamps and drills.

In the process of work, you need to remember about the possible heating of the tool and stop the motor for a rest during the work.

Each job requires a certain amount of equipment power. Therefore, to create chess figures, you need a miniature machine, and to create a figured sideboard lining, the dimensions of the bed and the energy drive will have different parameters.

Is it possible to create a metal lathe from a drill

In practice, more monumental equipment is used for metal processing. It is important to have a welded stable frame, since the forces acting on a rotating metal rod are much greater. The emphasis on the machine is on a reliable, screw-moving caliper. It is he who serves as the fulcrum for the cutter. A solid fastening of the drill with clamps creates a reliable attachment point for the workpiece in the chuck.

The entire structure is welded, including the tailstock. Only such a monolith can reliably take loads during metal processing. On a lathe from a drill with your own hands, it is permissible to work with small workpieces made of soft grades of metal. The material is processed using gentle methods - a file, a needle file, sandpaper. If you need to work on deep processing, to create a profile with cutters, you need an adjustable support.

The entire structure is welded, including the tailstock. Only such a monolith can reliably take loads during metal processing. On a lathe from a drill with your own hands, it is permissible to work with small workpieces made of soft grades of metal. The material is processed using gentle methods - a file, a needle file, sandpaper. If you need to work on deep processing, to create a profile with cutters, you need an adjustable support.

It is better to understand how to make a lathe for iron with your own hands, the video will help:

What can be done with a lathe

Even at the design stage of the machine, turning attachments for a drill can be provided. One of them may be a copier. It is used to exactly repeat all the curly cuts on a wooden cylinder exactly according to the pattern. The problem is rewinding the engines, and the attachment to the drill will cope with this task. You can use a drill fixed on the bed for grinding, put a polishing pad on it.

Even at the design stage of the machine, turning attachments for a drill can be provided. One of them may be a copier. It is used to exactly repeat all the curly cuts on a wooden cylinder exactly according to the pattern. The problem is rewinding the engines, and the attachment to the drill will cope with this task. You can use a drill fixed on the bed for grinding, put a polishing pad on it.

Use the rotation of the workpiece to apply paint. With centrifugal spreading over the surface of the decorative layer, an unpredictable color mosaic is created. The first machine will awaken interest in creativity and your imagination.

Using improvised inexpensive materials, you can create an assistant with whom to sculpt exclusive things for your home. Art crafts made by one's own hands have been valued at all times.

Universal homemade drill machine - video

What kind of devices were not made from ordinary hand drill! This power tool is so versatile that you can save yourself the expense of buying multiple handheld machines.

Making a lathe from a drill over the weekend

Let's make a reservation right away - there are industrial designs that are sold in electrical equipment stores.

Having spent a certain amount of money, you can purchase a finished copy and process wood and metal products in a home workshop.

But domestic Kulibins are not looking for easy ways, and strive to make a home-made machine from improvised materials.

Primitive lathe from a drill

I must say that despite the apparent complexity, this is one of the most affordable devices in the manufacture. The technological level of the design is unlimited, and is determined by the materials that you managed to find.

What is the simplest lathe

Drawing for the manufacture of a homemade lathe

Machine bed (base)

It is the basis of any stationary power tool. It determines the relative position of the main parts of the machine, and ensures the stability of the structure.

If the bed is massive enough and has its own legs, the tool is installed on the floor and actually becomes stationary. The compact bed is mounted on a table or workbench, and then the machine can be easily moved to any convenient place.

Headstock

Responsible unit on which the spindle or chuck with a rotary drive is mounted. As a rule, in compact models, this unit can move along the bed, but only for setting the relative position of machine components or centering.

During operation, the headstock must be securely fixed. On large stationary lathes, this part is generally integral with the bed.

tailstock

A movable assembly that provides clamping of the workpiece to the spindle (chuck). Main principle- perfect alignment with the headstock. This component of the machine must move freely along the bed, allowing you to set the workpiece of any length.

A properly made tailstock has fine adjustment of the stop cone. After fixing the knot, you can adjust the clamping force.

handcuff

Acts as a caliper for a lathe. On a compact device, it is a stop for cutters held in the hands of the operator. It must be able to move along the frame and be securely fixed in the working position.