Lighting our apartments or houses can be done in many ways. Each method is to use various types lamps. As you know, most people use standard incandescent bulbs.

Also, many inhabitants of the planet switched to the use of fluorescent lamps.

Recently, however, the newest type of lighting, which we call LED, has just burst into our lives, and which can be used both as a primary and as an additional one.

The essence of LED lighting

Light-emitting diode

This type of lighting differs from all others in that the main light source is not a tungsten filament or inert gases, but an LED.

This LED is a semiconductor element that has the ability to emit light when an electric current passes through it. I would like to draw attention to the fact that various types of semiconductor elements can be used to create LEDs. Moreover, each type can emit light of a different spectrum, that is, a different color.

As a result, LED lighting can be used not only as the main lighting of the house or any room, but is also a very powerful tool for creating and emphasizing the original interior.

Thanks to the existence of LEDs, designers have been able to stylishly decorate various areas of apartments, houses, as well as landscapes and gardens.

Summing up what has already been said, we note that one of the principles for organizing this type of lighting is the supply of light either to the entire room (general lighting), or to individual parts of the room (local or local).

Also, experts use the combined method, i.e. a combination of general and local ways of supplying light.

In order to understand how beneficial LED lighting is, consider its positive and negative sides.

Advantages

Benefits include:

- High level of energy efficiency. A one watt LED can produce up to 120 lumens. Most LEDs on the market put out 50-60 lumens on average. For comparison, a one-watt fluorescent lamp can produce a maximum of 100 lumens, and a one-watt incandescent lamp can produce 24 lumens.

- If you create the right power supply circuitry, use high-quality components and ensure proper temperature conditions, then such lighting can work from 36 to 72 thousand hours. This indicator is 4-15 times greater than that of a fluorescent lamp and 50 times the operating time of an incandescent lamp.

- There is no need to use filters to obtain spectral characteristics.

- There is no inertia during the on and off processes (this is very important for installations with dynamic light supply).

- LED lamps and tape do not contain harmful substances (for example, mercury). This provides a very high level of security during use.

- Small sizes.

- High resistance to impacts and various vandalism.

- High strength.

- Lighting devices with low power do not emit heat.

- Such lighting is characterized by the absence of ultraviolet and infrared radiation. As a result, paint and furniture upholstery will not fade.

- The dependence of brightness on current strength, not voltage. This means that when the mains voltage changes, the LEDs will not flash.

Flaws

Like everything in the world, LED lighting, which can be used not only at home, but also on the streets, has its drawbacks. They consist in:

- high price;

- high requirements for the quality of the heat sink. To the greatest extent this applies to powerful LED lighting. High temperatures reduce its reliability. They also generate heat during their operation. However, its small size does not allow for its complete dispersion (to a large extent this applies to situations where powerful LED spotlights are used for indoor lighting). As a result, high-power LEDs need an external heat sink for their cooling;

- if the temperature exceeds 100 degrees Celsius, the LED will not work;

- the need for less voltage necessitates the use of a DC power converter. As a result, the lamp gets large and needs additional protection;

- most LED lamps that are produced for mains voltage cannot be operated through dimmers for incandescent lamps. Of course, there are those that can work through these dimmers, but their price is 10-30 percent more. At the same time, their brightness will change abruptly. Therefore, there is a need to purchase special dimmers.

Summing up, it can be noted that LED lighting for various types of premises has a very large number of advantages. Many disadvantages arise only when it is characterized by high power and must be used in specific conditions that are not inherent in the home environment.

Use of LED lamps

LED lamp in a standard base

Above, we noted that the creation of light in the house using LEDs can be both general and local. The first option involves the use of lamps.

Depending on the area of the room, you can use one lamp, which will be located in the center of the ceiling, or many lamps, which will be dispersed over the ceiling area. These lamps are equipped with LED bulbs.

Manufacturers equip such lamps with standard bases, making their installation an elementary procedure. However, this is not the main difficulty. It lies in the correct selection of the lamp, or rather in its power.

Next, we will point out what needs to be considered in order to provide high-quality indoor lighting using LED lamps. Experts note that the main criterion in this is the luminous flux, which is also called light intensity or brightness. This value is measured in lumens.

Our main task is to determine the maximum number of lumens, i.e. the required level of light intensity in the room. Further, starting from this figure, we will choose the LED lamp itself.

One bulb creates from 1200 to 1300 lumens. Let's take a smaller value - 1200 lumens. The total lumens requirement is 2400.

As noted above, a one watt LED can produce 120 lumens. However, lamps of this quality are very expensive and hard to find on the market. Usually they sell lamps that can give out 50-60 lumens per watt. We will consider 50 lumens.

As a result, it turns out that in order to illuminate the aforementioned room, which can be located in any building, you need to buy an LED light bulb with a power of 48 watts (2400/50 = 48).

Of course, you can use either one powerful bulb or four bulbs with a power of 12 watts. This already depends on you.

We will also emphasize that this is the most simplified way to organize the process of creating light in a house using LEDs.

Helpful Hint: In practice, this process requires taking into account reflection light, light emission angle, luminous flux, operating temperature, and wall and ceiling color. It is difficult and it will be better if this work is entrusted to specialists.

Features of LED strips

As for the local lighting of the room, it can be done using LED strip.

Useful advice: the use of such tapes cannot be a full-fledged replacement for LED-based lamps. These tapes are able to highlight a certain space and create a very good visual effect. They are not characterized high level power.

In addition, they need low voltage, which can be either 12 or 24 volts. Also on the market you can find 36 and 48 volt tapes, but they are used very rarely. Looking at this, they need a power supply.

LED strip in reel

The tape itself is flexible printed circuit board, on which manufacturers place LEDs, limiting resistors and connecting wires. The maximum length of the tape can be five meters. All LEDs are divided into groups. Each consists of three units.

Such a group is indivisible and it is impossible to cut the LED strip in the middle of the group. You can only cut in certain places. Each manufacturer designates these places.

This type of lighting strip can produce both white light and other colors of light. In the latter case, such a tape is called an RGB tape. Unlike a simple tape that has two tracks, an RGB tape boasts four tracks.

Selection of a power supply

It is worth noting that the organization is a simple procedure and you can easily do it yourself.

To carry out this process, you also need to stock up on a power supply and connectors (they are used to connect several LED strips), as well as a cable with a socket.

In order for such lighting to work effectively, the power supply must have the same power as all the tapes connected to it + some more margin. To select this block, you need to determine the length of the required strip with LEDs.

Each manufacturer of such tapes indicates the total power of the LEDs, which are placed on one meter.

You also need to multiply the required number of meters by the power of one meter. This way you will know the total power of your local lighting. Next, the resulting figure must be multiplied by 1.5 (we take into account the power reserve). In the end, you will get the number of watts that the power supply itself should have.

Implementation of local lighting

When you have the necessary elements, you can start creating LED lighting in the house with your own hands. This process includes the following steps:

- Connecting to the power supply of the LED strip with the required length.

- Connecting a cable with a socket to the power supply.

- Installation of all components in the right place.

- Connecting the block to the network.

Useful advice: it is recommended to connect no more than five meters of LED strip to one power supply. Of course, you can take a very powerful unit that can withstand 10 meters of such a tape. However, this is not desirable, since at the beginning of the tape the diodes will overheat, and at the end they will receive less current. As a result, they will glow with less brightness. Therefore, it is recommended to use two less powerful power supplies.

In the case when you need to connect two parts of the tape, then they are connected in parallel. For this, connectors are used.

Using RGB Tape

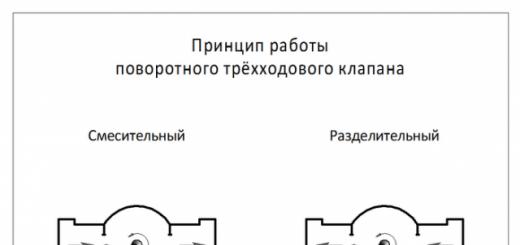

In cases where you use an RGB tape, you must use an RGB controller that connects to the power supply. Further, an RGB tape is connected to this controller. It has four wires, three of which represent the three primary colors: red, green and blue. Actually, they are painted in these colors.

There are four outputs on the controller, which are labeled V +, R, G and B. Red, green and blue wires are connected to the last three. The remaining wire is connected to the fourth output V +. This controller is controlled by remote control.

You can also learn about the features of creating such lighting from the video:

The article is intended to show all the pitfalls and costs in the use of LED strip as the main lighting.

Initially, for the main lighting of one of the rooms where overhaul, an ordinary chandelier was planned. But recently, I came across a super-bright Ultra 5000 LED strip with smd 5630 LEDs from the Arlight brand. The decision was made quickly, finally and irrevocably - I want such a tape as the main light in the room.

Theoretical brightness

The manufacturer claims that the Ultra 5000 smd 5630 tape provides a luminous flux of as much as 1200 lm per meter. For comparison, the luminous flux of a 100-watt incandescent lamp is about 1600 lm.

In my case, 15 meters of tape laid around the entire perimeter had to be used for a room of 14 m 2. The resulting luminous flux, it seems, cannot be calculated by simply multiplying lumens by meters.

I decided to wonder how to correctly calculate the total luminous flux, but, after googling, I realized that this task cannot be solved with a swoop. I need to spend n-th time studying the theory of lighting calculations using the luminous flux utilization factor method and somewhere to find some data unknown to me:

- reflectivity of walls, ceiling, other objects;

- honest luminous flux of one LED tape;

- characteristics of the profile diffuser in which it was planned to place the tape;

- voltage drop along the tape and the dependence of the LED luminous flux on it.

In the end, I decided that I would just do it and see what happens. But, just in case, I also bought a dimmer for LED strips. Suddenly it will be too bright 🙂

Theoretical spectrum

Bright LEDs are, of course, cool. But, one thing is brightness, and another is the spectrum of light.

If again compared with an incandescent lamp, it is good because it emits light in a wide range, its spectrum is relatively uniform and in some part close to the spectrum of sunlight. Such light is familiar and pleasing to the eye, it does not irritate or tire.

The spectrum of white LEDs is significantly different from the spectrum of an incandescent lamp, and not for the better:

White LEDs in this case are of the phosphor type, two humps on the spectral characteristic are formed from the emission of a blue LED (blue region of the spectrum) and a phosphor (yellow region of the spectrum).

In my lower brain, I knew that I should be careful with the use of LED lighting and leave the usual chandelier as well. Who knows how the eyes will react to such a spectrum. It is also hardly possible to calculate this in advance.

By color temperature, I chose the tape middle of the three options offered by the manufacturer - the so-called. Day White, 4000 K. Just seemed the most pleasant.

Accessories

Profile

I have a simple stretch fabric ceiling, without any multilevels and cornices, and since it was planned to place the lighting perimeter tape under the ceiling in plain sight, it was necessary to ennoble its appearance, but make it as inconspicuous as possible. Wondering which profile to use, straight or angled? It turned out that the intensity and uniformity of illumination did not visually change from the direction of the glow of the LEDs of the tape located near the ceiling. What is down, along the wall, what is along the ceiling, what is at an angle to them - the same. This is understandable, the passport glow angle of these LEDs is 120 °, but in reality it turned out to be close to 180. Therefore, the angle of the tape was not important, and I chose a straight profile as the most compact:

Ribbon

Tape Ultra 5000 is supplied from the factory on spools of 5 meters, the tape cutting ratio is 10 cm, the store cuts for sale in multiples of a meter. In my case, I didn’t have to cut, I took three whole packages:

The width of the tape is 12 mm, it does not fit into the selected profile quite normally, but it fits:

Power supplies

Passport power consumption of 15 meters of tape - 240 watts. Calculated by real measurement - 180 W (measured on a 3-meter segment, the current consumption was 3 A).

But, in addition to power consumption, there is also a factor of voltage drop along the tape, which leads to a gradual decrease in the brightness of the glow towards its end. Power supplies for LED strips (all or not - I don’t know, but those that I took - yes) allow you to power one common load in parallel. To equalize the brightness along long powerful tapes, instead of one power supply at one end, two less powerful power supplies are turned on at both ends of the tape, and in especially difficult cases, also in the middle of the tape. In my case, the perimeter is closed, I divided it in half, and simply took two 130 W power supplies and connected 7.5 meters of tape to each separately:

The choice of sealed power supplies was due to the fact that they have significantly smaller dimensions compared to open ones and do not have coolers, that is, they do not make noise, which is important. In addition, I planned to place them all in a sealed (for fire safety) shield, located in a hidden place inside the closet, where there are problems with heat dissipation.

Dimmer

The dimmer that I liked the most in terms of functionality from those that were available was originally designed for wall installation:

This dimmer has both mechanical brightness control and remote control. Moreover, in addition to smooth adjustment, the remote control has four buttons for preset brightness levels (25%, 50% 75% and 100%), and four more buttons for programming user levels.

But for connection, it requires four wires, which I did not have in the walls. So I made the decision that Dimmer I will install in the shield along with power supplies. By mechanically adjusting the brightness level, I will only set the starting level when the tape is turned on, and I will adjust the desired brightness with remote control.

But this will require soldering IR receiver:

take it out on the wire from the shield and place it in a convenient, inconspicuous place. Will it work like this? Checked it works:

Looking ahead, I note that the dimmer has one significant drawback.

The role of the memory of the brightness level set before turning off is performed by a potentiometer. When 12 volts is applied to the dimmer, the tape turns on at the brightness level that was set by the potentiometer. After that, the brightness can be changed both from the remote control and the potentiometer. But, regardless of how the potentiometer was installed, in the first moment when turned on, the dimmer does not immediately start the PWM, and a clean 12 volts comes out. At the moment of switching on, the tape necessarily flashes for a fraction of a second at maximum brightness, and then it is set to the specified one. It hurts badly in the eyes.

Amplifiers

The dimmer power was not enough for my tapes. I had to buy extra amplifiers- one for each power supply:

Shield mounting

In addition to the main lighting, I decided to use another 3 meters of the same tape for local lighting above the cabinet, with a separate wall switch and limit switches in the sliding doors. And I also planned decorative lighting from a simple LED strip and a night light on duty on a short segment of a dim tape with switching on from a photo relay. All this is not directly related to this article, but since it was necessary to place an additional three different power supplies in the shield, this should be mentioned. Initially, the photorelay has a rather large size and an unaesthetic appearance, so I also wanted to hide it in a shield so that it does not loom before our eyes:

I did the same with him dimmer- soldered the sensor and brought it out on the wire, after checking that this would also work:

I found a sealed shield of suitable sizes:

Zatar corners and fasteners:

And proceeded to install:

The shield is ready:

Mounting profile and tape

To increase the light output, it would be desirable to mount the tape not close to the ceiling, but a little lower, at least 5 centimeters. In this case, the reflection of the light from the tape from the ceiling will be better. But I didn’t have such an opportunity for some subjective reasons, so I mounted it close to the ceiling.

On the left is a piece of profile for the local lighting tape above the cabinet, mounted on the lower end of the eaves, behind which the decorative lighting tape will be located:

It is easy to cut a profile with a hacksaw for metal with a fine tooth exactly at an angle of 45 ° if you use a miter box, for example:

The profile was fastened with gypsum-tapping screws 32 long directly into the drywall, without dowels (the drywall is glued to the walls on Perlfix), having previously drilled holes in it (in the profile) with a step of half a meter:

Then he laid the tape in a profile, soldered the power wires. The perimeter profile has not yet been closed with a diffuser (the store has not yet delivered part of the diffuser), only the local lighting profile above the cabinet has been closed:

First power on

So - let's turn it on!

Wow! It's awesome!

Of course, I'm not blind from the brightness. Bright, yes, but not overwhelming. And very beautiful!

Flash photo:

Without Flash:

View from the street (4th floor):

I tried to photograph the difference in illumination between the tape and the 200 W incandescent lamp, which I still hang instead of a chandelier. I fixed the camera settings with one light source, launched the camera for a series of shots, and in the meantime switched the light source. Here's what happened.

First, I tuned in to the light of an incandescent lamp and launched a series, the first photo is a lamp, the second is a tape:

Now, on the contrary, the first is a tape, the second is a lamp:

An interesting effect - under the light of the tape, there are almost no vertical shadows. This can be seen, for example, by the shadow from the horizontal pipe and the missing shadow from the vertically located regulator knob on it.

These pictures show that 15 meters of tape shines brighter than a 200 W incandescent lamp. But it seems like not much. In fact, the comparison is certainly not entirely correct. The light bulb is a point source, and the tape is a distributed source. Under the light of a lamp, the corners of the room are much darker than in the center, and under the light of a tape located around the perimeter, it is equally light everywhere.

I measured the illumination with a luxmeter:

Here are the results in numbers:

As can be seen from the table, the illumination under the light of the tape differs slightly between different measurement points in the room, near the floor, at eye level, in the corners or in the center - the difference is no more than 2-3 times. Of course, this is a consequence of the uniform distribution of a large number of point light sources along the perimeter of the room. What is not observed in a light bulb that hangs in the center of the ceiling - the difference at different points reaches almost 30 times.

When turned on at the same time, both the lamps and the tapes of their illumination were simply summed up.

If someone explains to me on the fingers why the lumens do not add up directly (or add up?), And the lux add up (maybe this is a consequence of the large difference in the spectral characteristics of the LED and the lamp in the long-wave region?), And how with a declared light intensity of 1200 lumens per meter when measured at a distance of 1 meter from a piece of tape 4 meters long, the illumination is only 530 lux, I will be very grateful.

On a small segment, I put a diffuser on the profile, took a picture of the difference at a short shutter speed:

I measured the illumination at a certain distance: without a diffuser 600 lx, with a diffuser 520 lx at the same distance. Absorbs more than 10%. It is a pity that there is no diffuser for the entire perimeter yet, so as not to assess the overall decrease in illumination.

Voltage drop

The voltage along the tape drops significantly.

At the beginning, it was 11.5 V, and at the end of a segment of 7.5 meters it was already 8.5 V. Total - 0.4 Volts per meter.

The drop in brightness is not striking, but if you specifically compare it, you can see that in one corner the tape is much brighter than in the other.

Measurements with a luxmeter at a distance of about 30 cm in opposite corners of the perimeter gave results of 1600 and 600 lux, a difference of more than 2.5 times. Measurements at other distances gave the same difference of 2.5-3 times. Therefore, the value of 530 lux in the table for measurements at a distance of 1 meter from the tape is a certain average value, measured at a distance of about 2 meters from the beginning of the tape.

Tape heating, shield temperature

The tape heats up, and heats up noticeably.

At the beginning of the tape, the temperature of the aluminum profile was 55 ... 57°C, but at the end it was already quite cool, about 30°C. When the diffuser is installed on the profile, the temperature does not differ significantly.

Inside the sealed shield at maximum load (which is unlikely to happen in reality), the temperature also did not rise above 57 ° C after a 4-hour run. This is slightly higher than the passport operating temperature of the power supplies, but it didn’t stink of burning, everything worked. In normal operating mode, when only the perimeter tape is turned on, the temperature in the shield was set exactly at the level of the power supply rating of 45 ° C. Quite satisfactory.

Summary

I am quite satisfied with the technical side of the LED lighting system. Convenient and easy installation, high-quality components, turning on the light without delay (which is not provided by all power supplies for LED strips), silent operation, moderate heating, low consumption with high light output. There are only two minuses, but both are in principle solvable - the voltage drop along the tape (although the total illumination in the room is already quite enough), and the incorrect operation of the dimmer at the time of switching on (you can solve it by introducing a delay circuit for turning on the tape after turning on the dimmer, but then instead of flashing it will be this is the delay, I don’t know which is better).

It's too early to talk about the operational side, it takes time.

The first impression is that this light is completely different. And you can't say it's better or worse. Just different.

For several days I was engaged in assembling furniture while lighting the tape, I did not feel any discomfort. In general, while I like everything.

I did not like the financial side - the whole system cost me about 20 thousand rubles. The cost of a meter of tape in the profile is approximately 1 thousand rubles. Plus power supplies and other equipment. It's not known exactly how long this will last. For LEDs, a service life of about 100 thousand hours is declared, by which time they lose up to 30% of brightness. If you use the tape an average of 5 hours a day, then it should last for 50 years. We'll see.

HOUSE AND PLOT WITH YOUR HANDS

The ceiling illuminated by LEDs is, in principle, a well-known technology for a long time. As soon as LEDs appeared on the market, and this was already in the seventies of the last century, cunning radio amateurs began to enthusiastically experiment with lighting design. The imperfection of the LEDs themselves slowed down the widespread use of LED ceiling lighting. In particular, a very sharp spectrum and a rather small selection of colors. The first LEDs were quite bright and their light hurt the eyes.

Today you can find LEDs of any color, with a soft light that is gentle on the eyes. Even special assemblies of LEDs for lighting design are produced in the form of strips with fixed LEDs. They also come with special power supplies, as well as controllers that regulate the brightness and color of the radiation.

To engage in lighting design now, special education and even just special knowledge are not required. There are simply a myriad of options, but the article will consider the most popular and, at the same time, the most technically difficult - the illumination of stretch and suspended ceilings. If you can do this, working in lighting design will not present any particular difficulties for you.

LED backlight can be of the following types:

Here are four possible ways to illuminate a false ceiling:

1. Contour diffused illumination. In this case, the light sources (LEDs) are located on the shelf, the light is directed upwards. The illumination is obtained by a continuous strip of light.

2. Backlight directional. The LEDs are mounted on a slope, the lighting is directed along the ceiling.

3. Spot lighting (also called "starry sky") LEDs mounted on the ceiling are directed straight down. This is already more complicated and LED strip is indispensable here. However, too global technical knowledge is not needed here either.

4. Curly illumination. LEDs are placed in ceiling lamps specially designed for this purpose. Here only technical knowledge is indispensable, it is desirable to have the skills and abilities of a home master.

How to make ceiling lighting with LED strip?

Directional or contour illumination of the ceiling with LED strip - simplest way lighting design, while giving incredible scope to your imagination. Technical points - the choice of tape, power source, some installation nuances. First, let's talk about technology, then about installation.

Choice of LED strip.

First of all, color. Without a doubt - a full-color RGB tape is required with a controller. In terms of price - the ribbon costs the same as a single color, the controller itself is cheaper than ribbons of complementary colors. You are undoubtedly interested in why single-color ribbons are needed at all. The answer - in order to carry out the backlight at a great distance, when the price of equipment matters. That is, when highlighting shop windows, banquet or other large halls, trees.

Emitter density. It can be on tape 30, 80 and 120 per meter. If you are going to make contour lighting, the density should be more - 60 or 120, for directional lighting - 30 or 60. If the installation niche is of sufficient size, then it is better to install a pair of tapes on the shelf - 60 and 120, and on the slope 30 and 60. True, with such an installation, four power sources are needed, of course with controllers, but the range of lighting effects will be simply the widest, because in this case the tapes can be turned on and adjusted together. You can invent a lot of lighting effects - intersecting rays, double light border and the like.

Tape power. LED strips are designated by the letters SMD, as well as four more numbers. For example SMD 3028. The first two digits indicate the power that the tape consumes. For example, SMD 3028 tape is less powerful than SMD 6035. And twice. Also, the power of the tape meter must be indicated in its passport. It is easy to calculate further. For backlighting along the contour, 8 W / m is enough, for directional - 5 W / m. It is better to attach tapes for 7 and 12-14 W to the shelf, and 5 and 7 W to the slope. This will make it easier to adjust the light and make it possible to get by with cheaper controllers that do not have brightness control.

Total backlight power. This parameter depends on the length of the light strip. The required footage is measured with a tape measure, multiplied by the power of one meter of tape.

Power supply. we select the controller based on how much power is required to illuminate a certain light strip. Be sure to check that the supply voltage is correct. The operating voltage of light strips can be 5, 12, 24 Volts. Accordingly, the power source should give the same amount, and the controller should be designed for the same voltage.

Mounting diagram for directional and contour lighting

A few tips for installing LED strip in a plasterboard ceiling.

1. Mounting on adhesive tape

The LEDs are mounted on adhesive tape, where the adhesive layer is only on the reverse side and is covered with a protective film. Before you start mounting the tape, you need to find a PVC corner that fits the shelf and slope in size. Fix it with small self-tapping screws in a niche. Velcro will stick to PVC forever, and it can peel off from drywall over time. This must be taken into account. If the backlight is mounted on stretch ceiling, you can’t do without a PVC corner, because for anyone, even the most minor repairs the backlight will have to be removed.

2. Soldering

Solder the wires to the tapes very carefully and carefully. Both the LEDs and the plastic base do not like overheating. Flux is best suited for soldering - paste, solder POS - 61 or the same type, so that the melting point is no more than 160 degrees. You will have to solder "with one touch". If you've never soldered small parts before, don't risk it. Invite the master.

3. Connecting to the controller

It is not necessary to connect the tape with segments of more than 3 meters. Tracks for conducting current in a plastic base may simply not withstand a large current. Connect each three-meter section to the controller with separate wires.

4. Observe polarity

If you are doing the wiring yourself, remember to accurately observe the polarity and purpose of each wire. That is, "+" from the power source to the "plus" of the controller, respectively, "minus". From the controller to +V,R,G,B to the corresponding tape terminals.

5. How to cut the tape

Cut or cut LED strips, if necessary, only along the cutting lines that are marked in advance by the manufacturer. In addition to the last section, but it is necessary to cut with wire cutters - side cutters or very sharp scissors, strictly in the middle between the diodes, in one motion.

So it turns out that do-it-yourself LED lighting is quite achievable and does not require special knowledge. But the aesthetic effect is great. Once you have gained experience, you can enhance it even more by using other types of lighting.

Based on materials from the site: http://svoimy-rukamy.ru

Useful tips on how to make LED lighting in the kitchen

A good design idea is always complemented by the choice of optimal room lighting.

It is especially important to think it over in the kitchen. The right choice of light sources and their location is the key to a comfortable pastime on it. Among the many options, the choice often falls on the use of diode backlighting.

LEDs themselves are semiconductors. The passage of electricity through them provokes the emission of light, the brightness of which depends on the composition of the diodes. Such lighting cannot be mounted directly.

This will cause the tape to kink and break.

LED ceiling lighting: from tape to "starry sky"

It is also necessary to use stabilizers.

To understand how to make diode lighting in the kitchen, you need to figure out what purposes it is designed for, what types of tapes and their specifics are, what tools and additional materials are needed. Only after that you can start installation, guided by the instructions below.

Advantages of LED backlight

The choice of this kind of lighting for the kitchen is due to its resistance to mechanical stress and durability.

So, the service life of the tape can exceed 14 years, even if it worked for more than half a day. LED backlight provides good bright illumination and does not require warming up. Also, the advantage of its use can be considered the presence of a diverse color palette, including infrared and ultraviolet tones.

LED backlighting is quite affordable, safe and environmentally friendly.

It does not require a special temperature regime of the environment. The tape can be used with different beam angles.

The main options for using diode lighting in the kitchen

LED lighting is used for many purposes, namely:

- for zoning space or highlighting individual niches, cabinets, etc .;

- lighting of various kinds decorative elements(for example, paintings);

- decoration of glass shelves and stained-glass windows;

- internal lighting of cabinets and drawers;

- highlighting the kitchen apron (best suited to the glass version);

- illumination of multi-level ceilings;

- creating the effect of "floating furniture" with the help of lighting from under the cabinet, bedside table, etc .;

- bar counter design.

The number of crystals in it affects the color scheme of the ribbon.

If they are of different brightness, then 15 million shades can be achieved. Warm tones are more suitable for classic designs, while cool tones are more suitable for high-tech.

Types of tapes and their features

Often used are SMD LEDs, which can be divided according to several criteria:

- by glow - monochrome and full color;

- by the number of crystals - 1-4;

- in size - from 1.06X0.8 mm to 5.0X5.0 mm.

When choosing a tape, you need to clearly define the purpose of using the backlight.

If this is a decoration, then a single-chip SMD 3528 is enough. For brighter lighting, it is better to choose a three-chip SMD 5050 tape.

LED strips are small LEDs that are located in the same plane. The brightness of the lighting and the amount of energy consumed depend on the density of their placement. There are options 30,60,120,240 pieces/meter.

According to moisture resistance, several groups of tapes can be distinguished:

- IP20 - unstable (do not choose for the kitchen);

- IP65 - medium level of resistance (possible kitchen use);

- IP68 - full resistance to moisture (suitable even for lighting pools).

LED lighting of the kitchen work area

For such lighting, a tape with an average level of resistance to moisture is sufficient.

Its special coating protects against contaminants, vapors, and all sorts of liquids. Wet cleaning can be carried out, including light bulbs.

For installation, you can use an aluminum profile, which will hide the wires. There are also self-adhesive tapes. If you want to change the colors of the backlight or its brightness, you can install additional equipment.

The best option for decorating the work area would be ribbons that give white light.

Otherwise, the color of the food may be distorted.

You can also use LED lighting as an additional source. To do this, it is better to choose a tape with complete resistance to moisture. They will be attached with double sided tape. By combining ribbon options, you can successfully decorate the work area.

Necessary materials and tools

Installation of LED backlight should begin with the preparation of the necessary components and tools:

- complete set (12 W tape reel, electric cable with a diameter of 0.74 mm2);

- 12 W power supply and switch (sometimes with a control panel);

- soldering iron;

- electrical tape or a special tube;

- scissors;

- roulette;

- double-sided tape;

- aluminum profile;

- if necessary, a drill and mounting brackets.

Do-it-yourself backlight installation instructions

After all preparations, you can proceed to direct installation.

Since we want to make the correct and beautiful LED lighting of the working area in the kitchen, it is necessary to follow the given sequence of actions:

- From the standard length of the tape (5 meters) you need to cut off too much.

To measure the required length, you can use a tape measure. You can only cut in a certain place.

- It is necessary to expose the extreme contacts 1.5 cm from the silicone coating.

- Solder two cables to them.

It is necessary to solder in the designated place (marking +/-) for no more than 10 seconds at temperatures up to 260 ° C.

- Insulate with tape or heat shrink tubing (cut off a piece of the tube (2 cm), determine the soldering point and fix it using a building hair dryer);

It is better to use a tube, as it is more reliable and looks more aesthetic.

- On the outside of the profile, you need to attach adhesive tape, and on the inside - cleared of protective film tape.

Glue the latter on a fat-free, clean surface.

- A power supply unit is installed near the backlight attachment point. The cleaned wires of the tape must be soldered to it from the low voltage side.

On the other side of the power supply, an electrical cable with a plug is attached.

- The wires are connected in parallel and lead to the power supply.

- It is necessary to hide the wires in a plastic box (fix them with wiring brackets).

- Connect the switch and carry out the final installation of the power supply.

Thus, different LED strips can not only illuminate the working area in the kitchen, but also decorate it with different colors or functionally separate it.

And using the above instructions and tips, you can easily mount the diode backlight from A to Z with your own hands.

|

Proper lighting is one of the components of a spectacular design of any room.

It is especially important in the kitchen, where the correct distribution of the light flux turns cooking into a pleasant and comfortable process. All that is needed for this is a project and calculation of lighting.

How to make comfortable lighting in the kitchen?

One of the most interesting options in modern interiors, which you can do with your own hands, is the illumination of the LED strip.

LEDs are special semiconductors that emit light when electrical energy passes through.

LEDs can have different chemical composition, due to which the brightness of the light generated by them differs. There is one more nuance - the installation of LED backlighting is never carried out directly, because this way the tape can overheat and break.

A prerequisite for connecting LEDs is the presence of a stabilizer.

Benefits of LED lighting.

LED backlighting has a number of obvious advantages:

- Resistance to mechanical external damage;

- Durability - kitchen lighting tape is able to work for 14 years or more even when working more than 15 hours a day;

- A variety of colors - lighting in the kitchen under the cabinets can be made in white, red and orange, green and blue, purple and yellow.

You can also choose LEDs that work in the infrared and ultraviolet spectrum;

- Excellent lighting brightness, and the device does not require time to warm up;

- Affordability (due to distribution and popularization);

- Possibility to use a tape with a different angle of radiation;

- Safety;

- Environmental friendliness;

- Undemanding to room temperature.

Ways and places for interior lighting in the kitchen.

The number of crystals directly affects the number of colors in the ribbon.

In general, LED strips can provide 15,000,000 shades - if they combine crystals of different brightness.

You can make LED backlight for the following purposes:

- Combined lighting for zoning, allocation of cabinets, niches;

- Highlighting paintings or other decorative elements of the interior;

- Highlighting a kitchen apron, the backlight looks especially impressive if the apron is made of glass;

- Lighting inside drawers and cabinets.

- Highlight stained glass or clear glass shelves.

- By installing the backlight at the bottom of the bedside tables, that is, under the cabinets, you can create the effect of "floating furniture".

- Illumination of several levels of the ceiling.

- LED bar lighting creates the atmosphere and style of a real bar.

Installation of warm spectrum LEDs is carried out for classic interiors, and in a high-tech style, cold light will be more appropriate.

Choosing the right LED strip - classification and comparison.

Most often, the installation of LED backlighting is carried out from SMD LEDs. They are classified according to a number of criteria:

- The number of crystals - from 1 to 4;

- Glow type - full color or monochrome;

- Dimensions - in the range of 1.06x0.8 to 5.0x5.0 mm.

Before you buy an LED strip, you need to decide what type of lighting you want to make.

- The SMD 50x50 strip with three-chip LEDs is perfect for lighting the work and dining areas and can provide a uniform bright light.

- For decorative lighting, a single-chip SMD 35x28 tape is suitable.

Light-emitting diode strip (LED) is a series of small light-emitting diodes located within the same plane.

It can also have several varieties depending on the density of the LEDs:

- 30pcs/meter;

- 60pcs/meter;

- 120pcs/meter;

- 240 pieces/meter.

The power consumption and the level of brightness of the generated lighting depend on the number of LEDs.

The tapes are divided into groups and according to the degree of moisture protection:

- IP33 - not suitable for the kitchen, because it does not withstand high humidity;

- IP65 - medium level of moisture protection, can be used in the kitchen;

- IP68 - full moisture resistance - even a pool can be illuminated with such a tape.

How to choose a power supply for LED lighting.

Power supplies come in different capacities, and hence the size.

We need to determine the best option so that the transformer has enough power with a margin, but at the same time, so that it is not too large.

But since we need a margin, we will also take into account the coefficient equal to 1.25 - it turns out 1.25 × 60 = 75, therefore, we need to buy a transformer for 75 watts.

How to light up a kitchen countertop.

For the working area, a device with an average degree of moisture protection is suitable - it has a special protective layer that protects against vapors and pollution, water and other liquids.

This means that if necessary wet cleaning you will be able to wipe the cabinets along with the lamps.

Mounting the tape to the table involves attaching a special aluminum profile. It is necessary to hide the wires and give the lighting aesthetics. You can also make backlight from self-adhesive tapes.

By the way, by installing additional devices, you can create a backlight that will change brightness and / or color.

Advice!

For the desktop, a warm one is optimal White color LED strips because it won't change the natural colors of the food.

From LED strips to working area you can make additional lighting. It also requires structures with high protection against moisture. Tapes here are installed with double-sided tape. You can use multiple ribbons to create an expressive decorative effect.

What you need to install kitchen lighting.

Self-installation of LED backlight will require the use of the following tools and accessories:

- The kit itself: a tape reel (12W), an electric cable with a cross section of 0.74 mm2;

- Transformer - 12W power supply and dimmer with control panel (if any);

- Solder with rosin;

- soldering iron;

- Scissors;

- Double sided tape;

- Insulating tape (or heat shrink tube with a building hair dryer);

- PVC corner and or aluminum profile for mounting LED - if necessary;

- Drill - if necessary;

- Electrical mounting brackets - if required.

Installation of lighting in the kitchen.

Installation is carried out in the following sequence:

1. In the reel, the tape is most often 5 m long.

Most likely, you need less, so cut off the excess. The required length is measured with a tape measure and cut off in a strictly defined place, after which the extreme contacts must be carefully exposed from the silicone coating by about 1.5 cm.

Solder 2 cables to the contacts (preferably) or connect them using connectors (not recommended).

3 . Then perform insulation (tape or tube). To isolate the wires with a heat shrink tube, you need to cut off a small piece 2 cm long, put it in the soldering place of the wires and fix it with a building hair dryer.

What to choose - a tape or a tube - is up to you, but a tube is better, as it is more reliable and looks better.

4 . An adhesive tape is attached from the outside on a corner or profile, and a tape is fixed from the opposite part after removing the protective film.

A transformer must be mounted near the backlight. This place needs to be thought out in advance. The cleaned wires of the cut tape are soldered to it from the low voltage side. On the opposite side, a plug with an electric cable is attached. The LED strip is attached to a pre-cleaned and degreased surface.

The wires are connected in parallel and lead to the installation site of the power supply.

7 . The installation of a plastic box for wires is certainly carried out, where the wire is fastened with electrical mounting brackets.

And then the dimmer is connected, that is, the switch and the final installation of the power supply. A dimmer and amplifiers will be required if you plan to change the brightness of the backlight during operation.

These devices are mounted together with the power supply.

Installation of LED strip in the kitchen is ready.

Questions and discussion on the forum:

Auxiliary information.

Once we were ordered a closet, and the client was thinking about how to effectively illuminate the areas with clothes hanging on hangers. We suggested that he run the LED strip in a special light cable, as we usually do in dressing rooms. But the question arose about how to turn it on. The customer did not want to install a conventional switch, and turning on the light every time after opening the door is not very convenient.

A separate touch sensor inside the closet also meant pulling wires to it and laying a cable channel. It's all bulky and not very pretty inside the closet. It is advisable to install the sensor not one, but on each door, since there are three clothes rails in each compartment.

After some thought, the client himself suggested solving this problem with the help of Ikeevskaya lighting.

We read the specifications on the Ikea website, found out the dimensions of the lamps themselves and included them in the wardrobe drawing.

At first we agreed that we would buy everything we needed from Ikea and install it.

But then the client decided to do it himself. He asked us to run electrical wires to the places where the fixtures were attached and hide them in the cable channel. We have done everything.

A few months later we again got to the old customer in the apartment. Now we made a closet in the hallway.

We asked the client about the result of his work on lighting. It turned out that everything looks very good.

Really good lamps. They shine quite brightly, yellow, warm light.

LED lighting in the interior: do-it-yourself options and installation

The sensor turns on the light when the door is opened, no additional sensors and extra wires are needed. The wires that come from the lamp are thin enough to be able to disguise them, put them through the small holes in the shelves that we have prepared.

These lamps are called in the Ikea store - "*Striberg". (*Ikea later renamed the fixture "Norrfly")

The dimensions of this LED backlight are as follows: 350mm, 420mm, 550mm, 670mm, 920mm.

The width of each cover is 38mm.

It has a micro switch that has three positions - automatic, on, off.

Following from the names - "automatic", this is the work of the sensor.

The door opened, the light turned on.

"On" is when you want the light to stay on all the time.

Well, “off”, respectively, when you need to turn off the light.

Be careful when buying "Striberg", the price is for the lamp itself and the power supply, excluding the cost of the wire for connecting to the network, as well as the connecting cable if you need to connect the lamps to each other.

Study the annotation on the Ikea website, or consult the seller.

The beauty of these lamps is the absence of separate sensors and additional wires. They are very easy to install and connect to the mains. No difficulties should arise.

There are practically no cons.

There are size restrictions, well, someone may seem overpriced.

If you need to highlight one section in the closet, then the option with a "streeberg" is very suitable.

Below you can watch a video in which we show these very “streebergs”.

And here is the closet itself, which we did before this lighting.

Below is another video in which we show how we installed such a backlight in the dressing room.

Below is a video - How to put the backlight from Ikea yourself.

All articles

Today, “special” repairs are in fashion, which provide for non-standard solutions. These include the original ceiling lighting with LED strip.

Today, “special” repairs are in fashion, which provide for non-standard solutions. These include the original ceiling lighting with LED strip.

The room in which such an LED strip on the ceiling will be mounted will have a very unusual look.

Also, such a tape can sparkle in all sorts of colors, which allows you to use different design effects in the room.

How to install LED strip on the ceiling - you ask? And it’s very easy - even someone who is little familiar with electrics or with it “for you” can do this work at home.

What is LED strip?

An LED strip is a flexible mounting strip on which small LEDs are located at the same distance from each other.

The thickness of the tape, as a rule, is two to three millimeters, and the width is eight to ten millimeters. It is realized in the form of a coil with a length of five meters. You can buy on the market or in a hardware store as many meters as you need.

There are a variety of LED strips that differ in special parameters.

They give preference to the type of tape, depending on the location of the necessary lighting, its color and the humidity of the room.

The following parameters are recognized:

- Ribbon glow color. There are LEDs in every color of the rainbow. And in the case when it is not easy to choose a color, then you can buy an RGB tape with an RGB controller that will modify the tones depending on the setting.

- The type of LED affects the brightness of the LED: SMD-5050 and SMD-3528 differ in radiance.

- The number of LEDs may vary - from thirty to two hundred and forty LEDs.

More of them per 1 meter of tape will give more intense light and more energy will be consumed.

- The degree of moisture protection. Yes, also a necessary parameter, the LED strip is susceptible to moisture. As a result, if it is supposed to be installed on the ceiling in the bathroom, then you need to buy a waterproof type (from IP-65 to IP-68).

Preparation before installation

First you need to predetermine the desired length of the LED strip.

They measure the total perimeter of the ceiling plinth / cornice, on which the tape with LEDs will be mounted.

DIY LED lighting

Illumination tone and light intensity are selected individually. Excessively saturated (dazzling) LEDs do not need to be purchased so that they do not glow through the plinth, as stated above.

After that, you can take up the “correct” selection of the power supply of the required power.

If multi-color backlighting and color change control are planned, then an RGB controller is required. This point needs special attention.

Installation of LED strip in the ceiling plinth

For those who do not want to reconfigure the ceiling and put a plasterboard cornice on it, the method of mounting the LED strip on the plinth on the ceiling will do.

In this case, you need to opt for wider, thicker ceiling plinths, because the LEDs shine quite strongly and a thin foam plinth can shine through.

All the time you need to install the LED strip on a surface that is free of grease, smooth and not crumbling.

1. First, the ceiling plinth is strengthened with a special method: it should not reach the ceiling, that is, there should be a small gap so that it is possible to stretch the LED strip.

1. First, the ceiling plinth is strengthened with a special method: it should not reach the ceiling, that is, there should be a small gap so that it is possible to stretch the LED strip.

On the opposite side, the LED strip has an adhesive backing. This protective layer must be removed and the tape can be glued. This feature allows you to extremely quickly strengthen the LED strip.

3. Prior to gluing, it is necessary to check that there is no dust or construction waste on the ceiling plinth. Otherwise, soon the tape may simply peel off.

If the length of the tape is not suitable, it can be cut off. This must be done in specially prepared places, according to notes.

5. If there is a need to connect several parts of the tape, then everything is done using special connector connectors.

Of course, you can solder two connectors using other wires, however, the temperature in the soldering iron cannot be more than two hundred and sixty degrees, and soldering should not last more than ten seconds.

Next, the delivered tape is connected to the power supply. For this purpose, there are wires soldered at the factory at the ends of the tape. It is very important: do not confuse “plus” and “minus”, “input” and “output”, be sure to carry out this work strictly according to the instructions.

7. If a multi-color or controlled LED strip is used, then the power supply and strip must be connected with the controller.

The power supply is powered by a 220 volt network through conventional terminal blocks. "Zero" must be connected to N-, and the phase to L +. In the case of backlighting without a controller, the voltage to the PSU is transmitted through a conventional switch.

9. It is better to hide the PSU and the controller behind a plinth, in some niche, but be sure to make sure that the niche is ventilated.

It is not allowed to install the PSU in a closed space, that is, where there is no air.

Installing LED strip in plasterboard cornice

First, the cornice itself is erected using the plasterboard ceiling technology.

However, at the same time, the ceiling is not completely sewn up, but only part of it. Of course, the ways to install the LED strip are very diverse, but in our example we will consider the following option, which you can do with your own hands without much effort and with little desire.

At a mark below the ceiling fifteen centimeters around the perimeter, the UD (PN) metprofile is fixed to the wall. Further, at a mark ten centimeters below the cornice, a similar profile is strengthened on the ceiling, on which pieces of the CD profile (PP - 27-60 mm) of fifteen centimeters are placed every forty to fifty centimeters.

To combine the design, pieces of the CD profile are cut off along the exact width of the cornice and thrown eight to ten centimeters over the side.

On the sides of the CD profile, cuts are made for the sides, after eight to ten centimeters. They are embedded in the UD profile on the wall, parallel to the CD profiles, and combined with each other using fasteners. The sides are wrapped, fixed in the corners with self-tapping screws and they get a hidden drywall shelf to accommodate the LED strip.

Then the tape with LEDs is installed on a hidden shelf and connected.

Next, you need to think about the wiring for the fixtures and the tape itself, run the wires in necessary places and with the help of drywall, sew up the cornice from all sides, strengthening the drywall and onto the hidden shelf. Then they glue the LED strip on a hidden shelf and connect it.

LED LIGHTS

APPLICATION - UNDERWATER - ARCHITECTURAL

Widely used today, LED lamps of various types originate from the 60s of the last century. It was then that the first lighting device was developed, which used a special type of semiconductor.

Its peculiarity lies in the fact that when passing through such a conductor of electric current, it generates light radiation.

Depending on the scope and design, there are two main types of LEDs:

Lighting.

Used with different tones of white light. Act as an element of lighting lamps.

They have two wires. Indicator.

They have more colors. They are used for decorative purposes or to indicate the state of machinery and equipment. There are four wires connected to the device. An example is the IR diode on wireless remote controls.

LED APPLICATIONS

Due to a number of unique features, LED backlighting has found application in various fields.

Luminaires based on LEDs are used as the main or additional light source in residential buildings, office and shopping centers.

The technology is widely used for decoration purposes. With the help of diodes, original lighting effects are created in the design of an apartment or to decorate cars.

LEDs are additional elements of LCD TV screens, computer monitors, information boards. They allow you to highlight the picture, providing it with deeper colors.

Color solutions in LED lighting.

A special polymer crystal acts as a semiconductor in LEDs. Most of these crystals are completely transparent in their inactive state. They create a certain color of glow only if an electric current is applied to them. To enhance the brightness of individual versions, a colored diffuser is used.

The variability of the colors of the glow of diode lamps is quite wide. There are options with white, green, yellow, red, blue illumination. Moreover, white lamps include several different tones. Also a separate segment are ultraviolet LEDs.

Features of organic LEDs.

Organic LED backlighting or OLED backlighting is one of the directions for further development of the technology. In fact, the design of such devices is the same as that of the standard options.

The only difference is that the polymer crystal here is made using separate organic compounds, which react more actively to electricity.

Most often, such diodes are used in LCD screens of TVs, laptops, phones and other equipment.

The main advantages of LEDs.

Such a wide application of LED backlighting has acquired due to an impressive list of advantages. The main ones include:

- economy in use due to low electricity consumption;

- high strength and resistance to mechanical stress;

- resistance to action low temperatures;

- instant operation without long warm-up and no flicker;

- no toxic emissions during work;

- ease of disposal.

UNDERWATER LED LIGHTS

Decorative lighting is used not only in the interior, but is also one of the most important elements of landscape design.

At the same time, not only decorative garden elements, flower beds and paths are illuminated, but also gazebos, terraces and other recreational areas and decorative areas.

The presence of a reservoir, fountain or pool on the site is also isolated by specialized lighting, which emphasizes all the beauty in the dark.

Underwater lamps can be attributed to the main elements of such specialized lighting.

Such lighting elements are based on LED technology and are considered the most optimal for use for this purpose. Among the tasks of underwater LED lamps are:

- focusing on the object (shapes, architecture, materials and color performance);

- giving effect to water and decor, which is under water.

Types and features of underwater lamps.

Among the varieties of underwater lamps, one can single out both monochrome and color LED strips, as well as individual lamps with the effect of dynamic lighting, a gradient.

Particularly interesting are special lamps with a remote control that allows you to change the intensity of light, the color of the light beam, focusing, depending on your own preferences, time of day, season.

Underwater LED lights are good because they are safe for humans (a special power supply unit converts the usual voltage from the network to 12 V), designed and created in such a way that they perfectly tolerate external influences (shocks, precipitation, temperature changes).

In addition, LED-devices are economical and consume much less energy (compared to ordinary light sources).

Do-it-yourself LED strip lighting

The use of underwater lights.

There is a place for such lighting not only in an outdoor pool: especially resourceful people use them as decorative and functional lighting for home aquariums. Diodes in the water column shine more softly and diffusely, beneficially affecting the local flora and inhabitants.

On the plot, underwater lamps are used for:

Illumination of artificial waterfalls.

Light sources, installed directly behind the falling stream of water or next to the source, allow you to create intricate highlights on the trickles of a decorative waterfall.

Illumination of decorative ponds.

In this case, two types of lighting are often used - static and rotary LED lamps for local illumination of a specific area. Illuminated outdoor pools.

In this case, stationary and rotary lamps on the walls and bottom are also used.

The advantages of choosing LED lighting for swimming pools, fountains and ponds include a durable body of devices that is resistant to corrosion due to special processing and ease of installation, which greatly facilitates self-installation.

LEDS IN ARCHITECTURAL LIGHTING

Not always the usual street lighting is enough to decorate the facade of the building, so designers resort to the use of LED lighting as an additional light source and decorative element of architectural structures.

With it, you can decorate various elements of the building - the roof, door and window openings, the porch.

Benefits of using LEDs in architecture:

- original decoration and the possibility of emphasizing individual elements of the architectural complex;

- the ability to hide visual flaws in the design of a building or room;

- creating a light, joyful atmosphere, which is well suited for the holidays;

- a way to emphasize the status of the institution;

- territory delimitation.

Operation at low temperatures makes it possible to use LED lighting devices outdoors.

LED lamps do not contain harmful, toxic substances, and therefore are environmentally friendly.

Kinds of decorative LED ornaments.

Light-emitting diode (LED) garlands for the street are a fairly common way of lighting a building. One of the varieties of such products is LED duralight, which is an elastic light cord with many light bulbs inside.

Due to its high quality characteristics (resistance to temperature extremes, water resistance, flexibility), duralight is the most popular led product for interior decoration.

LED rain is well suited for interior decoration. Possible attachment points are above door and window openings, in niches.

LED curtains (curtains) are often used to decorate doors and windows.

The basis of such a device is a cord, usually made of plastic or silicone, to which wires (sometimes of different lengths) with LED lamps are attached.

Lamps come in different colors, their mode of operation can be adjusted to your liking. It is possible to fasten several curtains to create a large structure.

© 2012-2018 All rights reserved.

All materials presented on this site are for informational purposes only and cannot be used as guidelines and normative documents.

Making a 220 V LED lamp with your own hands is an interesting activity that requires patience. Additionally, you need a little knowledge of physics, and the ability to solder. The main task is to create a circuit for an AC-to-DC 12 V converter that powers an LED lamp.

LED lamp

Represents a small luminous diode element, powered by direct current, mainly 12V. To create lamps, they are assembled several times, depending on the required light intensity.. The advantages of such lighting:

- meager electricity consumption;

- service life from 100,000 hours;

- can work for days without shutting down;

- There is a wide range of different models available for sale.

The main disadvantage is the high cost of finished LED lamps. Sellers are not well versed in the issue and can not competently answer your questions. In the very characteristics of the lamp losses due to the passage of light through the scatterer are not taken into account, frosted glass and reflector properties.

The packaging of the luminaire contains calculated data based on the characteristics and number of LED elements. Therefore, in fact the luminous flux of the purchased lamp is significantly lower than required and the lighting is poor. The lamps themselves and the parts for creating circuits cost a penny. Therefore, it is easiest for craftsmen to do everything with their own hands.

Use of LED lights

In houses and apartments, constant lighting of a place is often necessary. It can be stairs and children's rooms, toilets where there are no windows, and a child lives in the house who cannot reach the switch.

Dim light and low energy consumption make it possible to install lighting in entrances and on the porch, in front of the gate and garage doors. Luminaires with a soft glow due to glare damping, used to illuminate desktops in offices and kitchens.

Making an LED lamp with your own hands

Many are tormented by the question of how to make an LED lamp with your own hands and is it possible. There are many schemes for creating LED lighting powered by 220 V AC, they all solve a number of common tasks:

When creating LED lighting with your own hands, you also have to solve problems:

- where to put circuits and LEDs;

- how to isolate the lighting structure;

- correct heat transfer.

Schemes of LED lamps

Aligning variable sweat and creating the necessary power and resistance for LED fixtures is solved in two ways. Schemes can be conditionally divided into:

- with diode bridge;

- resistor, with an even number of LED elements.

Each option has simple schemes and its own advantages.

Scheme of a converter with a diode bridge

The diode bridge consists of 4 diodes directed in different directions. Its task is to turn a sinusoidal alternating current into a pulsating one. Each half wave passes through two elements, and the minus changes its polarity.

In the circuit, for an LED lamp, a capacitor C10.47x250 v is connected to the positive side of the bridge from the AC source. A resistance of 100 ohms is placed in front of the negative terminal. Behind the bridge, parallel to it, another capacitor is installed - C25x400 v, which smooths out the voltage drop. It is easy to make such a scheme with your own hands, it is enough to have the skills to work with a soldering iron.

LED element

The board with LED elements is used standard, from a failed lamp. It is necessary to check before assembly that all parts are working. For this, a 12 V battery is used, it can be from a car. Non-working elements can be replaced by carefully unsoldering the contacts and putting in new ones. Pay close attention to the location of the anode and cathode legs. They are connected in series.

When replacing 2 - 3 parts, you simply solder them in accordance with the position that the failed elements occupied.

When assembling a new LED lamp with your own hands, you need to remember a simple rule. Lamps are connected 10 in series, then these circuits are connected in parallel. In practice, it looks like this:

- Put 10 LEDs in a row and solder the legs of the anode of one with the cathode of the second. It turns out 9 connections and one free tail at the edges.

- Solder all chains to the wires. To one cathode ends, to the other anode.

In texts, verbal designation of contacts is often used, icons on diagrams. Reminder for novice electricians:

- cathode, positive - "+", joins the minus;

- The anode is negative - "-", joins the plus.

When assembling circuits with your own hands, make sure that the soldered ends do not touch others. This will lead to a short circuit and burn out the entire circuit that you managed to make.

Schemes for a softer glow

In order for the LED lamp not to irritate the eyes by blinking, several details must be added to the assembly diagram. In general, the current converter consists of:

- diode bridge;

- 400 nF and 10 uF capacitors;

- 100 and 230 ohm resistors.

To protect against power surges, a 100 ohm resistor is placed first, and then a 400 nF capacitor is soldered. In the previous version, they are installed at different ends of the entrance. Behind the capacitor after the diode bridge, another 230 ohm resistor is installed. It is followed by a series of LEDs (+).

Resistor circuits

The most simple circuit for those who want to do everything with their own hands, it consists of two 12 k resistors and two chains with the same number of LED elements, lamps connected in series with different directions are soldered. From the R 1 side, one strip is soldered by the cathode, the second - by the anode. Another layer to R 2 is the other way around.

The most simple circuit for those who want to do everything with their own hands, it consists of two 12 k resistors and two chains with the same number of LED elements, lamps connected in series with different directions are soldered. From the R 1 side, one strip is soldered by the cathode, the second - by the anode. Another layer to R 2 is the other way around.

This creates a softer glow of the lamps, since the LED elements are lit alternately and the pulsation of the flashes is almost imperceptible to the eyes. Such lamps can even be used as local lighting when working at a table, thus replacing an ordinary table lamp.

Experts who have made more than one lamp with their own hands recommend collecting at least 20 LEDs for this circuit. 40 is more commonly used. This provides good lighting and the circuit is easy to assemble. For a larger number, it is difficult to produce high-quality soldering of the circuit without hitting adjacent contacts. Yes, and it is difficult to collect it in the case.

You can make a lamp from 4 or 6 more powerful LEDs. To calculate the schemes, use a special calculator that can be found on the Internet.

When creating various circuits with your own hands from LED devices and others, you can use an online calculator for the correct calculation. It is easy to find on sites that are dedicated to electrical appliances and descriptions of how to make them. Its use will greatly simplify the process of calculating the current strength, resistance and will allow you to check the correct selection of parts.

Housings for LED lamps

For convenient inclusion of a do-it-yourself LED lamp in ordinary lighting devices, use:

- socles of conventional incandescent lamps;

- housings from energy-saving lamps;

- halogen lamps;

- homemade fixtures.

Each specialist, making an LED lamp with his own hands, chooses the most suitable option. The base makes it possible to screw the lamp into a conventional cartridge and at the same time provides heat transfer. Overheating, the LED lamp fails faster.

Base with incandescent lamps

Carefully separate the glass flask and remove the spiral. Then a circuit is placed inside the base and lamps are attached to the top of the board. The disadvantage of such a base is in an unsightly appearance and poor insulation.

Energy saving lamp housing

The most convenient and practical option for creating an LED lamp with your own hands. Methods for mounting diodes can be different. First, the burned-out lamp is carefully disassembled. Then the converter board is removed from it. Next, there are options.

It can be placed in the holes of the lid, which are made for glass flasks. This is in the version of the lamp with three arc-shaped light elements. The circuit is located inside the base providing heat transfer. LEDs are inserted into ready-made holes and mounted in them.

The finished board with LEDs can be placed in the base using a simple plastic water bottle cap. You can use a self-made circle and drill holes for the diodes in it. As a result, it is convenient to use and aesthetically pleasing.

Some craftsmen, making their own hands, use the body of a halogen lamp. The inconvenience of this option is the absence of the usual opportunity for a base to screw the lamp into a cartridge. This option is more suitable for creating do-it-yourself indicators and DC lamps.

Most of all, the LED strip is suitable for stretch and plasterboard ceilings.

What is LED strip

An LED strip, or, as it is also called, duralight, has the form of a flexible conductive board with LEDs and resistors placed on it, which are responsible for the resistance.

Such a tape has a width of 8 to 10 mm and a thickness of 2 to 3 mm. If we are talking about a multi-color tape (RGB), then a controller is also attached to it, which will allow you to adjust the intensity of the glow and switch the lights, creating an atmosphere in the room that suits the mood.

How to make LED lighting with your own hands

When installing an LED strip, in addition to the strip itself, you will also need a power supply and connectors to connect the strip.

When choosing a power supply, you need to focus on its power. To do this, you need to make the appropriate calculations using the data given in this table:

To calculate the required power, it is necessary to multiply the power of one meter of the LED strip by its total length:

W/m x L tape = W

After the calculation, it is necessary to add another 20% to the result, because the “end-to-end” power supply will not be enough for the power supply and some margin is needed for its full and safe operation.

And now a little about connectors. As mentioned above, they will be needed to connect the tape to the power supply, as well as to other tapes, since many users are not limited to the standard tape size of 5 meters and add the same or even several tapes to it.

To connect with the connector, you do not need to resort to any tricks, you just need to move the clip, putting the connector on the edge of the tape and returning the clip to the opposite position. After that, you just need to correctly connect the wire from the connector to the power supply.

In some cases, a soldering connection method can be used, which, by the way, is much cheaper than buying connectors. The connection is very reliable and durable.

Important! When soldering contacts, it is very important to heat the soldering iron to a maximum of 250 degrees and solder no more than 10 seconds.

Connecting the LED strip

There are two types of LED strips:

Single color ribbon

Multicolor (RGB)

The principle of their connection is somewhat different, so it makes sense to consider their installation separately.

How to connect a single color LED strip

To connect a regular tape 5 meters long, you need to connect the wires of the power supply to the wires of the tape. There is a standard wire marking, indicating “+” in red and “-” in black. If there is no marking, you can measure the polarity with a multimeter, however, even if the polarity is not observed, nothing will happen to the tape, it simply will not glow.

If you need to connect more than one tape, then you need to place them not in series, but in parallel, because when connected in series, the tape can overheat and burn out.

This is how the connection diagram of one LED strip looks like:

This view has a parallel connection of two tapes: