To Category:

Technology of woodworking production

Circular and band saws for sawing logs and beams

Circular saws. The device of machine tools and their characteristics. Circular saws are divided into log sawing machines and beam sawing machines.

Log sawing machines can be single-saw, double-saw and multi-saw. Single saw machines are designed for sawing beams, sleepers and boards. They belong to heavy-duty machines, they consist of a cutting mechanism and a feed mechanism in the form of a mechanized trolley moving along rails. The cutting mechanism of single saw circular saws is simple in design. It consists of one or two shafts on which the saws are mounted.

Rice. 1. Scheme of a two-way light and sound alarm for double-deck sawmills: 1 - light and sound red signal from below "Do not release the brakes", 2 - response signal from below "Start", 3 - red signal from above "Start", 4 - control button of signals 2 to 3, 5 - the door of the guard of the parcel mechanism, 6 - the door of the guard of the connecting rod

Modern single-saw circular saws are equipped with a loading device, consisting of a transverse storage conveyor and mechanisms for piece-by-piece delivery of logs to the cart, and a remote control. These machines include the TsDT6-4 machine. The maximum cutting height of this machine is 800 mm, the maximum saw diameter is 1250 mm.

The main purpose of two-saw and multi-saw machines is sawing thin logs. The machines differ in the design of the loading device, for which some of them use longitudinal conveyors, on the chain of which stops are installed, pushing the logs to the end. To hold the log, the upper or lower part of the conveyor is shaped like a chute.

For longitudinal sawing of beams and segments, multi-saw circular saws are designed. They usually have a roller material feed and are equipped with a front-stay table. The saw blades of the cutting mechanism are mounted in movable and fixed blocks on one saw shaft. Machines differ in the number of saws and power.

Rice. 2. Circular saw machine TsDT6-4 for sawing logs: 1 - cutting mechanism, 2 - dial indicator for measuring the transverse feed of logs, 3 - trolley, 4 - rack, 5 - rail track

Work on machines. Single-saw circular saws model TsDT6-4 have remote control from the remote control, taken out of the zone of possible departure of the sawn material.

First, a log is piled on a cart and unfolded. This operation is carried out with the help of the piece-by-piece issuance of logs installed on the accumulative platform, and the mechanism for turning logs, which are controlled from the same control panel as the machine.

After installing the log on the trolley, the machine operator turns on the machine. When the saw blade reaches full speed, the machine operator turns on the cart feed. Having finished the cut, the machine operator puts the trolley on reverse and returns it to its original position. By turning on the mechanism of the transverse movement of the log on the cart and setting the log for the next cut, he repeats the cycle.

The material intended for sawing on the Ts8D-8 machines is fed to the storage platform located on the side of the front machine table. With the help of the chain sections of the storage platform, the material moves to the non-drive rollers of the table, where it is oriented relative to the saws with a guide ruler. The material is fed into the machine by means of a drive roller, which descends on the material after it has been installed and the guide bar has been retracted. The control of the machine table and the machine is concentrated on the control panel at the machine table.

Machine productivity. Circular saws have significant productivity. The speed of the working stroke of the trolley for the TsDT6-4 machines is 80 m/min, and the idle speed is 120 m/min.

Band saw machines. The device of machine tools and their characteristics. Band saws are designed for sawing large-sized, mostly low-quality raw materials and logs of valuable species. On fig. 52 shows a diagram of a band saw for sawing logs.

The vertical band saw machine has a bed on which two pulleys for a saw band are located. The lower pulley is the leading one. The brake device of the machine is connected with it.

Upper pulley - driven; it can move vertically, due to which the tension of the saw is ensured. The saw blade is put on the pulleys and stretched using the load linkage 9, which causes the top pulley to rise. The working branch of the saw band runs in two guides designed to reduce the free length of the working section of the saw and increase its lateral stability when sawing. The more stable the saw blade is in operation, the better the cut. The lower guide is fixed fixedly on the foundation

Rice. 3. Scheme of a band saw plant for sawing logs: a - equipment layout plan. 6 - diagram of a band saw; 1 - vertical band saw machine. 2 - roller conveyor, 3 - rail track, 4 - trolley, 5 - trolley drive, 6 - platform with control panel, 7 - device for accumulation, piece delivery and pile of logs on the trolley, 8 - lower pulley, 9 - cargo mechanism, 10 - upper pulley, 11 - saw blade, 12 - mobile racks with grippers, 13 - mobile cart frame, 14 - saw blade guides

stove. The top guide can move vertically and be set depending on the diameter of the sawn log.

An integral part of the band saw installation is a trolley on which the sawn log is fixed. The trolley is equipped with mobile racks with grippers (hydraulically driven) for fixing the logs. The racks move in the transverse direction with respect to the trolley frame along the guides for installing the log relative to the sawing plane. Rack drive mechanical (reducer, electric motor, rack and pinion). When the trolley reverses, its frame with uprights and a log moves away from the cutting plane.

The trolley moves along the rail track with a winch driven by a hydraulic motor with stepless speed control over a wide range.

A mechanized device is installed in front of the machine for accumulating, piece-by-piece issuance, piles of logs on a trolley, as well as for turning logs. Behind the machine there is a roller conveyor for receiving sawn boards.

One of the most important parameters of band saws is the diameter of the pulleys, which determines the largest diameter of the sawn logs, the thickness and width of the saw, and the power of the machine. Increasing the thickness and width of the saw allows you to increase the feed rate and at the same time maintain a stable position of the saw during sawing, which is necessary for high-quality sawing of logs.

On band saws it is possible to cut logs with a diameter of up to 1.5 ... 2 m. The thickness of band saws does not exceed the pulley diameter Vlooo, and the width is 350 ... 400 mm.

Modern band saws models LB125-1 and LB150-1 have a pulley diameter of 1250 and 1500 mm, respectively. The machine LB150-1 is designed for sawing logs with a diameter of 20 ... 125 cm. The speed of the working stroke of the trolley for these machines is 80 ... 125 m / min, the reverse - 125 m / min. On the LB150-1 machine, saws with a thickness of 1.6 and a width of up to 230 mm can be used.

The main advantage of band saws is less (compared to sawmills and circular saws) waste of wood into sawdust and high productivity.

The considered band saw machines belong to single saw machines for individual sawing of logs, since sawing of logs is carried out on them in successive cuts. For group sawing, band saw lines are created on the basis of double, quadruple, etc. band saw machines, which are distinguished by high cutting performance of raw materials.

At present, the LBL150-1 line has been created for cutting logs based on dual band saw machines with program settings. The line consists of a store for creating a stock and piece-by-piece issuance of logs, a device for receiving, turning and centering logs, a mechanism for clamping a log and feeding it into sawing, a double bandsaw sawing machine for sawing logs by sequential pair heating of slabs and boards, a roller conveyor for removing sawn timber from the machine and the line control panel.

Pulley diameter 1500 mm, working speed 5 ... 60, idle - 80 m / min.

Work on the machine. The band saw machine, including the trolley and near-machine mechanisms, is controlled by one person from the central console located on the platform.

First of all, the mechanisms that feed the log to the trolley and turn it are turned on, then the trolley mechanisms that ensure the installation and fixing of the log. After that, the trolley drive is turned on to feed the log for sawing.

When the log passes the machine, a command is given to reverse / trolley to return it to its original position. Then the mechanisms that move the log to the thickness of the sawn part are turned on, and the cycle repeats. For the transverse installation of the log, a servo drive on non-contact selsyns is used. When the log approaches the predetermined position, the travel speed is automatically reduced, which ensures more accurate installation.

The sequence of operation of the LBL150-1 line is as follows. The logs arriving at the command of the operator from the store are turned by a tilter around the axis and are clamped in the movable rods with the help of a pneumatic cylinder. At this time, the saw blocks are set to the required cut size, and the stops of the roller conveyor are set to the working position.

After the first pass, the log stops, the saw blocks are automatically retracted from the cut line by 10 mm and the mechanism

log feed returns to its original position. For the next pass, the saw unit is shifted by the thickness of the sawn board.

At the end of sawing, the core board is dropped onto a roller conveyor, and the spread bars return to their original position to clamp the next log. Sawing is controlled by the operator from the remote control.

The productivity of the machine depends on the diameter of the sawn logs and the number of cuts in the log. It is advisable to use the machines when sawing logs of large diameters (over 50 cm) and with a small number of cuts in a log (for example, when sawing out beams).

The number of cuts that can be made on band saws per unit of time (for example, per hour) depends on the qualifications of the worker, the degree of mechanization of near-machine work, and the condition of the equipment. The performance of the machine is determined in the same way as a circular saw with a trolley; line LBL 150-1 - as a circular saw machine with roller feed.

Wood, like natural stone, is one of the oldest building materials. Despite the huge selection of various artificially created materials that exists today on the construction market, timber products are still very popular. In order to obtain high-quality lumber, a log must be sawn into boards. In this article we will talk about how to cut a log into boards.

Types of sawing logs

Sawing a log into boards is carried out in two main ways:

- radial

- tangential.

In addition, additional methods are possible:

- mixed

- semi-radial (rustic)

- central.

Radial sawing is a type of sawing, during which the axis of the cut runs through the core of the log and, as a result, the annual rings in the section of the board form an angle of 76 - 900. The lumber obtained by this sawing has a uniform color and texture. Timber almost does not undergo deformation during shrinkage and does not swell when moistened, because the dimensions of the wood change mainly along the line of the rings (across the fibers). In radial sawn lumber, annual rings are arranged in thickness. Such materials have the highest performance in comparison with other types of lumber.

Tangential sawing is carried out along the tangents to the lines of annual rings at a small distance from its core. The surfaces of the resulting boards are distinguished by a pronounced texture and a bright wavy pattern of annual rings. Such lumber is characterized by higher coefficients of shrinkage and swelling from moisture, compared to radial sawn boards. As a result, they are strongly deformed under the action of moisture. Such boards are in demand for use in dry conditions.

Rustic (semi-radial) and mixed types of sawing have signs of two main types of sawing at the same time: radial and tangential. Therefore, they show average shrinkage and swelling ratios. Rustic sawn boards are distinguished by straight lines of annual rings, which are located at angles of 46 - 75 degrees. to the layers. Mixed sawn lumber is distinguished by the fact that the lines change from straight at the edges (in width) of the board, to arched towards the middle.

The central cut is made right in the center of the trunk and contains its core. Taking into account the fact that the core of the trunk is the wood with the lowest strength values, center sawn lumber is characterized by a structure that is not uniform in strength.

Wood balance when sawing

|

Log diameter |

Volume output,% |

||||

|

sleepers |

boards |

general |

sawdust |

piece. otkh. |

|

Log cutting tools

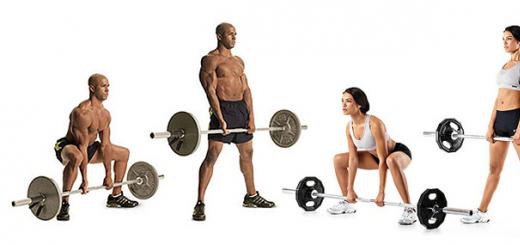

Tools and cutting methods depend on the total volume of logs, such indicators as length, thickness. In addition, the quality of the future lumber must be taken into account. Sawing logs involves working with different tools and specialized equipment. In order to get a small amount of lumber at home suitable conditions manual method of processing logs using a chainsaw or traditional hand saw-hacksaws with teeth for the longitudinal type of cut.

The sawmill is perhaps the most famous type of sawmill equipment. This is a woodworking machine in which there are frame saws. At the sawmill, longitudinal sawn lumber is obtained, for example, edged boards or timber. Sawmills allow processing logs with a diameter of 15 to 80 cm and a length of up to 7 m.

Sawing logs into boards using circular saws is carried out by means of a circular saw. Such equipment can be single-saw (single-disk) and multi-saw (multi-disk). Devices containing a single disk are suitable for working with small-sized and low-quality raw materials. With the help of multi-disc machines, it is possible to cut round workpieces of large diameter.

Band sawmills are the most popular today. They are of two types: vertical and horizontal. The cutting tool in such equipment is a tape that is put on the pulleys. Work on tape machines guarantees the production of quality longitudinal and mixed lumber, such as boards and beams. This generates the least amount of waste.

Band sawmills are the most popular today. They are of two types: vertical and horizontal. The cutting tool in such equipment is a tape that is put on the pulleys. Work on tape machines guarantees the production of quality longitudinal and mixed lumber, such as boards and beams. This generates the least amount of waste.

On large industrial enterprises use lines for sawing wood. They allow to achieve very high surface quality and precise geometry of the final products. Such lines are characterized by the highest productivity.

In addition to all of the above equipment, such types of highly specialized sawmill equipment are also used, such as debarking, edge trimming, band-cutting and other types of machines.

Very often there are situations when you need to make a very small amount of boards or beams for your own needs. Of course, buying machines in this case is absolutely not an option. Having certain knowledge and skills, it is much more profitable to cut logs with your own hands, using an electric or gasoline chain saw. Despite the fact that this work is quite laborious, the result is quite justified.

Most experts believe that a chainsaw is better suited for this purpose. Such equipment has high power and can operate without interruption for a long time. In addition, the operation of the chainsaw does not require electricity, so you can work far from the power supply, for example, right on the plot.

In order to cut a log into boards with a chainsaw, you will also need special tools, such as a mechanism for fixing the log, a frame attachment for a chainsaw, and a guide for cutting. The attachment frame must be attached to the chainsaw bar so that it is possible for them to adjust the gap between it and the chain. This will make it possible to create boards having different thicknesses. The chain should be purchased special, for longitudinal sawing. It has a special sharpening angle of the teeth. A guide ruler can be made from a metal profile of the required length or a flat rigid board.

In order to cut a log into boards with a chainsaw, you will also need special tools, such as a mechanism for fixing the log, a frame attachment for a chainsaw, and a guide for cutting. The attachment frame must be attached to the chainsaw bar so that it is possible for them to adjust the gap between it and the chain. This will make it possible to create boards having different thicknesses. The chain should be purchased special, for longitudinal sawing. It has a special sharpening angle of the teeth. A guide ruler can be made from a metal profile of the required length or a flat rigid board.

Before starting work, you need to remove all the bark and remaining branches from the blanks, as well as carefully examine the log for various flaws. In this way, you will be able to choose the most suitable cutting pattern and, consequently, reduce the amount of possible waste.

If you are ripping trunks, you need to make sure that the resulting lumber is of the same density across the entire width. Since the density of wood from the northern part of the log is much higher than from the south, the cut is carried out in a plane directed from east to west (or vice versa).

The first step is to remove the slabs from two opposite edges of the log. As a result, a two-edged beam will be obtained, which is then cut into boards or other lumber of equal thickness, according to the planned sawing pattern. The end product is an unedged board, from which the edges are necessarily removed.

For many centuries, timber has been the most popular raw material for housing construction. Today, primitive processing methods have been replaced by modern equipment. For example, for cutting timber and processing them to the desired size, craftsmen use a sawmill. The disadvantage of such a machine is the cost. For this reason, many people make mini sawmills based on chainsaws.

April 04All photos from the article

The construction market is replete with a huge amount of modern materials, which, unfortunately, do not differ in naturalness. That is why wood is still the most popular - due to its versatility and availability, it is used in various construction industries. Any lumber, whether it be timber or boards, is made from logs, so our task today is to understand how to make the necessary building material out of it.

Instead of a preface

- Logs can be sawn with hand tool, or on various professional equipment used on an industrial scale.

- The cost of finished lumber has a direct impact on its characteristics, namely the thickness of the materials and the amount of waste remaining as a result of the production process.

At enterprises engaged in the production of lumber, sawing lines are used. This equipment is highly productive and allows you to get a quality product.

Sawmill - a machine for cutting logs into boards

One of the types of sawmill equipment is a sawmill - a woodworking machine on which frame saws are installed. After processing, a timber and an edged board are obtained as a result.

Logs of only a certain size can be used as raw materials:

- length should not exceed 7 m;

- the diameter size range is much wider and ranges from 150mm to 800mm.

Round timber is also sawn on circular saws called circular saws or circular saws. These machines are divided into:

Most often, logs are processed on band sawmills, which allow sawing round timber both horizontally and vertically. Due to the high quality of sawing logs, very little waste remains after obtaining the final material.

But this is not the whole list of equipment used for large-scale production of lumber. There are also highly specialized machines that are used only in certain branches of woodworking.

The main types and methods of cutting wood

The method of sawing logs is selected depending on the type of wood and what kind of workpiece should be obtained as a result.

Take into account:

- parameters that determine the size;

- form;

- surface quality;

- requirements.

Logs can be sawn according to the location of annual rings.

In total, there are three types of sawing:

- Radial - along the radius of annual rings, while the work is carried out with particular clarity.

- Tangential - the log is sawn to the growth rings tangentially, parallel to one of the radii.

- Parallel-forming - cutting occurs parallel to the direction of the fibers.

Depending on the direction in which the logs are sawn, the methods of sawing them are also divided:

- In collapse - involves sawing a log in several places along its entire plane. At the same time, they should be parallel to each other. This is the easiest processing method, which ultimately allows you to get a pair of slabs and an unedged board.

- With slabs, it allows you to first get side boards and a beam, which, if necessary, is sawn into identical edged boards. This method allows you to cut a little more than half of all raw materials. The disadvantage is that the processing of round timber requires the use of two sawmills.

- Segmented - a beam will be cut from the center of the log. This name is due to the fact that two segments remain on the sides of the log, which are subsequently cut into tangential boards.

- Sector - round timber in this case is sawn into sectors. At the same time, their number depends on the diameter of the log and varies from 4 to 8. Further, the resulting fragments are sawn into radial or tangential boards.

- Circular - designed for individual cutting of logs. In this case, healthy wood is separated from the affected one.

Tip: sawing off the next board, the trunk must be rotated 90˚ around the longitudinal axis.

It should be noted that the last three methods, unlike the previous two - the main ones, are used quite rarely.

Sawing at home

It is unprofitable to purchase sawmills for use at home both from an economic point of view, the price is quite high, and from a practical point of view. For these purposes, a conventional chainsaw is quite suitable.

However, you can also use electric, but gasoline is much more powerful and does not require electricity, which is very useful when working far from civilization. Despite the complexity of this process, with certain skills, labor costs can justify themselves.

All work related to cutting requires special tools:

- a device that fixes the log in a stationary state;

- nozzle frame designed for a chainsaw - if you want to get boards of different thicknesses, they are fixed on the tool tire, but in such a way as to be able to adjust the distance remaining between the nozzle and the chain;

- guide lines. It can be successfully replaced with a metal profile or an ordinary board of the required length, as long as it is even and rigid.

Tip: for a chainsaw, you need to purchase a special chain that allows you to make longitudinal cuts. Her distinctive feature is a special sharpening angle of the teeth.

Process

The operating instructions will be as follows:

- Free the logs from bark and branches. The less waste you get, the more finished material will be.

- Determine the cutting pattern that will be the most optimal. Why inspect the log for possible defects.

- Saw in an east to west direction or vice versa. This is due to the fact that obtaining high-quality material is possible only if the density of the boards is the same across the entire width. Please note that the density of the tree trunk on the north side is much higher than on the south.

- Remove the slabs located opposite each other.

- Saw the double-edged timber formed as a result of this operation into lumber.

- Remove the edges from the resulting .

Tip: if any defects are found in the log, for example, a false core, it can be rotated as in circular sawing by 90 and 180˚.

Conclusion

If you decide to dissolve the log at home, you will have to use a sawmill, a chainsaw, or a regular saw. The first two options will show the best results, in addition, the process will be much faster and better.

Before starting work, it is advisable to draw a diagram for sawing round timber. The video in this article will provide an opportunity to find additional information on the above topic.

Wood is the most popular material given to humanity by nature itself. Furniture is made from it, houses are built and even dishes are made. But in order to use wood as a building or finishing material, special machines are required for its processing.

The most popular material from wood it is a bar with boards, from which many construction blanks are made, but this requires sawing a round tree. It is for this purpose that band sawing machines (sawmills) exist.

Band sawmills

This type of sawing machine makes it possible to obtain building material from roundwood in the form of boards and timber of various cross-sections and sizes with minimal waste. The board may not be edged, the edges of the board have a curved line, and edged (the edges make up a straight line). The bar can be square or rectangular.

The modern tool market today offers a variety of woodworking machines manufactured by domestic and foreign manufacturers. Among them are a large number of machines designed specifically for longitudinal sawing of round wood.

One of these is the tape model of the Taiga sawmill., which is by far the most demanded among entrepreneurs manufacturing lumber for construction, furniture industry and for other industries.

Band sawmill "Taiga"

Peculiarities

Distinguishing properties

"Taiga T-1"

This sawmill model It has small dimensions and is driven by an electric motor. It is used for sawing round logs, as well as large timber into boards.

This sawmill model It has small dimensions and is driven by an electric motor. It is used for sawing round logs, as well as large timber into boards.

It has a durable metal frame. When sawing, there is no oscillation of the saws (waves). Sawing logs of small diameter. Differs in the low price, and low consumption of the electric power. Small overall dimensions allow it to be transported even in a minibus.

"Taiga T-2"

It's practically an inexpensive machine. , whose power is only 7.5 kW. Its metal frame has a large margin of safety, which is designed for quite a long operation. The performance of the model depends on the type of product being processed, and can be approximately 5-10 cubic meters per meter. in shift.

Can be additionally equipped electronic ruler type Micron - 4, with the help of which full automation of control of almost all production operations is carried out.

The use of Micron - 4 helps the operator accurately, without errors, make a sawing map, mathematically calculate and make corrections for the thickness of the cut. In this case, all calculations are stored by an electronic ruler, which has 8 memory cells.

"Taiga T-2B"

According to their technical properties and performance, this model can be considered unique equipment. It is equipped with an economical drive from a four-stroke gasoline engine with a power of 10 kW (13 l / forces). When fully loaded, the engine consumes only about 1.5 liters of AI-92 gasoline.

According to their technical properties and performance, this model can be considered unique equipment. It is equipped with an economical drive from a four-stroke gasoline engine with a power of 10 kW (13 l / forces). When fully loaded, the engine consumes only about 1.5 liters of AI-92 gasoline.

To warm up the engine before the expected load, idling is provided, thereby extending its service life.

The design of the sawmill consists of a standard frame of the Taiga sawmill, but it provides fasteners for installation electric motor instead of petrol engine.

The T-2B machine can work in the field directly on a deforestation plot, where, of course, an electric line cannot be present.

Depending on the diameter of the sawn logs, Taiga-2B can cut about 10 cubic meters per one shift.

"Taiga T-2M"

This model of the band sawmill has a fairly powerful 11 kW electric motor, thanks to which it is possible to saw large-sized logs with dense wood.

Its design has a fairly large margin of safety, therefore it is designed for long-term, multi-shift operation with a capacity of up to 10 cubic meters / m. in one shift.

At this sawmill, as well as on the T-2 model, an electronic ruler of the Micron-4 type can be installed, which automates many work processes.

"Taiga T-3"

The T-3 sawmill is designed for multi-shift work with wood of any density. Power

its electric motor is 11 kW, has a reinforced design of the sawing carriage, due to which the diameters of the sawing pulleys are increased up to 60 cm, which increases the life of the tape blades several times.

The design of this model is designed for fairly high loads, with minimum fast settings. This allows you to work without long breaks to adjust the equipment.

The performance of the T-3 model is, when cutting large round timber, about 12 cubic meters / m. in one shift.

The function of moving the sawmill along the log being processed can be separately configured and additionally equipped to automate the workflow with a multifunctional electronic ruler of the Micron-4 type.

The design of tape models "Taiga"

The basis for the sawmill can be a concrete platform or thick wooden beams laid on a flat area of dense soil. Rails are laid on the bars or a prepared platform, which are rigidly fastened to each other. They also have a system for attaching processed logs.

The basis for the sawmill can be a concrete platform or thick wooden beams laid on a flat area of dense soil. Rails are laid on the bars or a prepared platform, which are rigidly fastened to each other. They also have a system for attaching processed logs.

The rails can be extended with an additional section, which makes it possible to cut logs, the length of which can exceed 8 meters.

The frame of the sawmill can be mechanically or electrically driven vertically and run on rails. with support rollers in manual mode. The saw cut is removed manually by one or two auxiliary workers.

The movement of the sawing mechanism along the vertical plane is carried out using a two-row chain transmission simultaneously with a lowering / lifting drive gearbox, and is controlled by a metric scale located on the frame. Thanks to this, the sawing mechanism is fine-tuned in height and firmly fixed on the frame of the sawmill.

On the sawmill of the T-1 series, the sawing mechanism is moved manually by rotating the gearbox with a special handle. And on the rest of the machines, the vertical movement of the sawing mechanism is carried out by an automatic switch, but if it becomes necessary to adjust the saw in height, then it is done using a manual closer.

The sawing mechanism is equipped with two balanced rollers (leading and driven) on which the cutting saw is fixed. The drive roller is driven by a belt drive from an electric motor pulley. The driven roller is attached to the tension system and rotates from the movement of the belt.

The speed of the band saw can increase with the increase in the diameter of the pulley, which can be a maximum of 520-600 mm. This improves the quality of the cut surface of the log and increases the service life of the cutting blade.

After installing the band saw, its tension is made with a special key with a dynamometer. Tension control is carried out on a scale located on the dynamometer sensor mounted on the tension wrench.

Constant tension and prevention of oscillation of the saw blade is carried out by the damping rollers of the sawing mechanism. The saw blade is equipped with a special lubrication system so that the saw blade does not get caught in the cut of the log, which can be caused by wood resin accumulated on the band. The system has a lubricant flow regulator, which simultaneously cools the cutting blade.

All moving and rotating parts of the sawmill are protected by a metal protective casing, and the machine is controlled through the sawmill keypad, which is installed on the saw frame.

Purpose and consumer groups

Preventive Maintenance

Preventive maintenance of sawmills consists in daily cleaning them of sawdust, lubricating the resting rollers and periodically inspecting all working mechanisms.

During service, worn parts are changed, mainly resting, as well as driving and driven rollers.